Mantle/Concave/Bowl Liner/Spare Parts/Wear Parts for Sandvik Cone Crusher

Shanghai Kinglink Industry Co., Ltd.- Certification:ISO 9001:2000, ISO 9001:2008

- Standard:GB

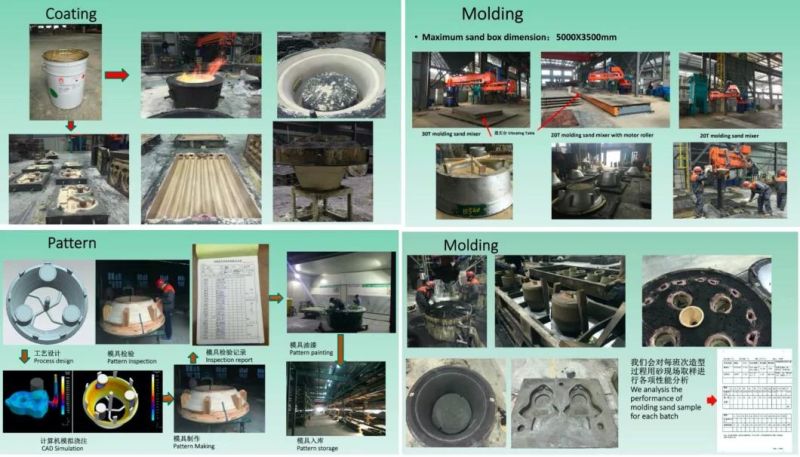

- Surface Treatment:Spray-Paint

- Manufacturing Process:Casting

- Material:Cast Steel

- Transport Package:Export Standard

Base Info

- Specification:Steel Maganess Chrome

- Trademark:kinglink

- Origin:China

- HS Code:84749000

- Production Capacity:1000sets Per Year

Description

Basic Info.

Specification Steel Maganess Chrome Trademark kinglink Origin China HS Code 84749000 Production Capacity 1000sets Per YearProduct Description

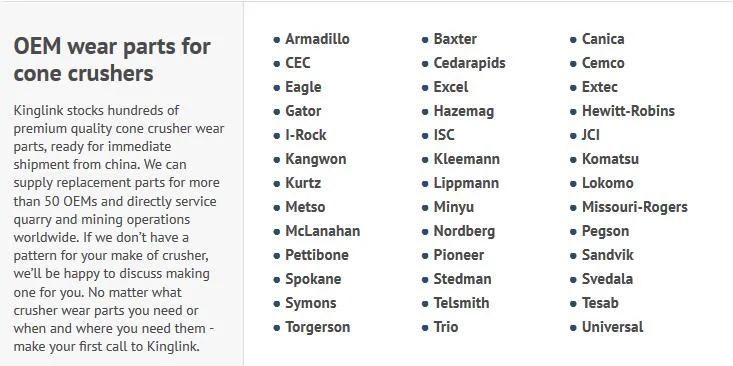

OEM for Metso and Sandvik Cone crusher wear parts

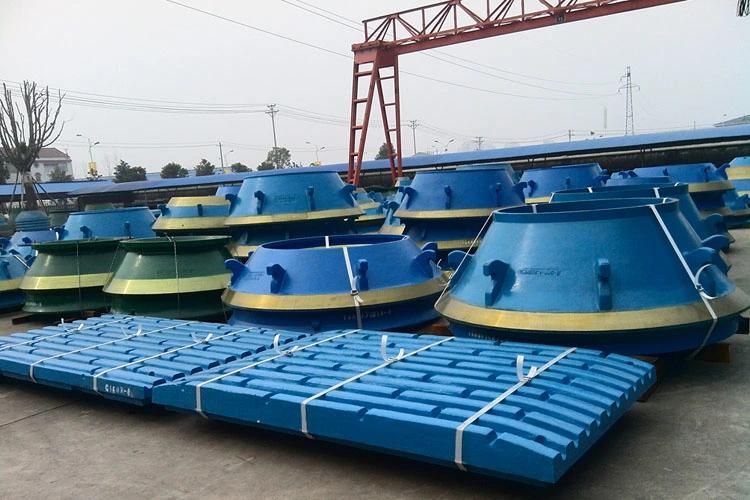

Our cone crusher wear parts are based on high-quality products with superior finish, supported by in depth knowledge of every aspect in the crushing process. Our mission is to work together with our customers to achieve the optimal crushing chamber application in terms of performance, cost-effectiveness and results.

Benefits

Based on data and comments provided by our customers worldwide, Kinglink offers the following benefits in many crushing applications:

- High quality and longer wear life

- Lower cost per ton of material crushed

- Savings in labor, backing material and downtime

- Long-lasting manganese steel and durable parts increase crusher uptime

Applications

Nordberg® GP Series™ Cone Crusher is designed to be the crusher of world advanced level. HP cone crusher is widely used in metallurgical, architectural, water and electricity, traffic, chemical industries.GP cone crushers are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc.

FAQ

1.Q: What products do you offer?

A: Kinglink provides parts are tailored with your requirements. It ranges mainly from METSO/Sandvik crusher parts, totally replacement parts, we also welcome OEM offer from you.

2. Q: What materials can you make?

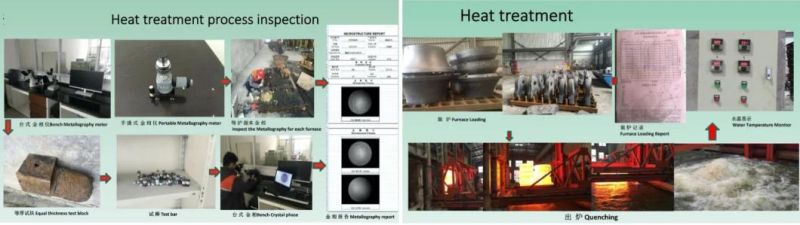

A: Our speciality is high manganese steel(Mn13, Mn18,Mn22 or customized formula), we also produce alloy steel,cast iron, high or medium chromium cast iron and bronze.

3.Q: How about the capacity?What's the max weight of workpiece that can be casted?

A: The capacity is 110 tons per workday. The heaviest workpiece we have casted is 18 metric tons.

4. Q: What information should we provide to you to confirm our order of parts?

A: For standard part, you only need to provide the part number than we will define the part. But others, you should provide the technical drawings of your parts.

Manufacturing Process

Our Parts

For any of your requirements on Metso and Sandvik Crusher parts, please feel free to contact us.