Grewin-Tungsten Carbide Mining Button Bits

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- Certification:ISO 9001:2008

- Standard:GB

- Surface Treatment:Polishing

- Manufacturing Process:Pressing

- Material:Tungsten Carbide

- Name:Tungsten Carbide Buttons

Base Info

- Matarials:Tungsten Carbide

- Wc:94%

- Co:6%

- Grain Size:0.8

- Hardness:91

- Trs:3800

- Surface:Polishing

- Tolerance:0.01

- Used for:Medium Rock,Hard Rock, Very Hard Rock

- Good for:Welding

- MOQ:1kg

- Quality:Super High

- Stock:Yes

- Fast Delivery:Yes

- Transport Package:Box Inside, Carton Ouotside

- Specification:SQ1015

- Origin:China

- HS Code:8208101900

- Production Capacity:10 Tons,Month

Description

Basic Info.

Matarials Tungsten Carbide Wc 94% Co 6% Grain Size 0.8 Hardness 91 Trs 3800 Surface Polishing Tolerance 0.01 Used for Medium Rock/Hard Rock/ Very Hard Rock Good for Welding MOQ 1kg Quality Super High Stock Yes Fast Delivery Yes Transport Package Box Inside, Carton Ouotside Specification SQ1015 Origin China HS Code 8208101900 Production Capacity 10 Tons/MonthProduct Description

Tungsten Carbide Buttons For Mining Drilling for Hard RockProducts description

Tunsten carbide buttons are mainly used for high and low pressure DHT drill and hydraulic Screw-in drill and so on. They are suitable for hot insert or cold pressing bit inserting process, With some of the materials used in the welding process. These products are stable in quality,Excellent in performance, can meet or exceed the domestic advanced level.

We are developing carbide grades use in crushing and recycling industry. Tire, plastic, metals and trashes that needs to break down and recycle. Weariness, toughness and resistance to acidy working environment are essential properties. Specific develop grades working with different crushing materials improves the runtime of your equipment.

Advantages:

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

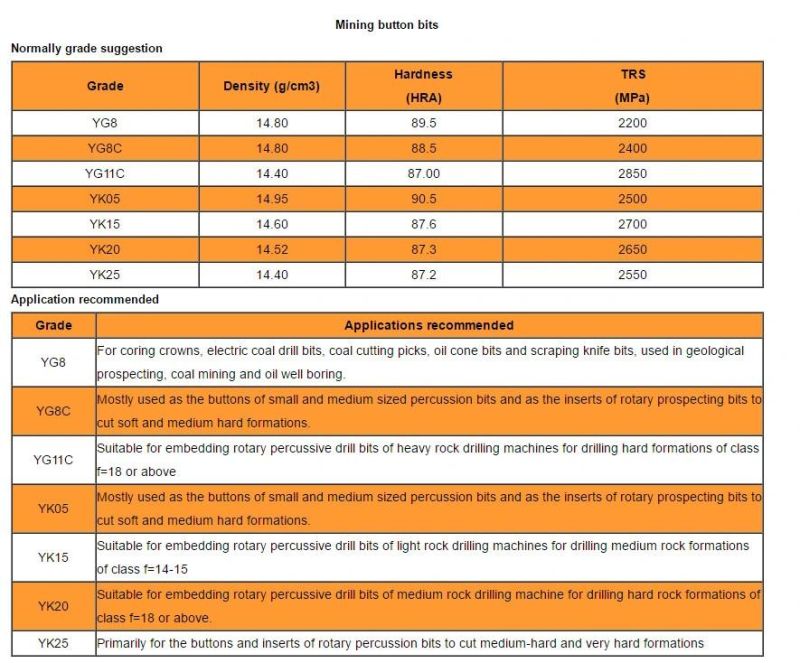

Grade Introduction:

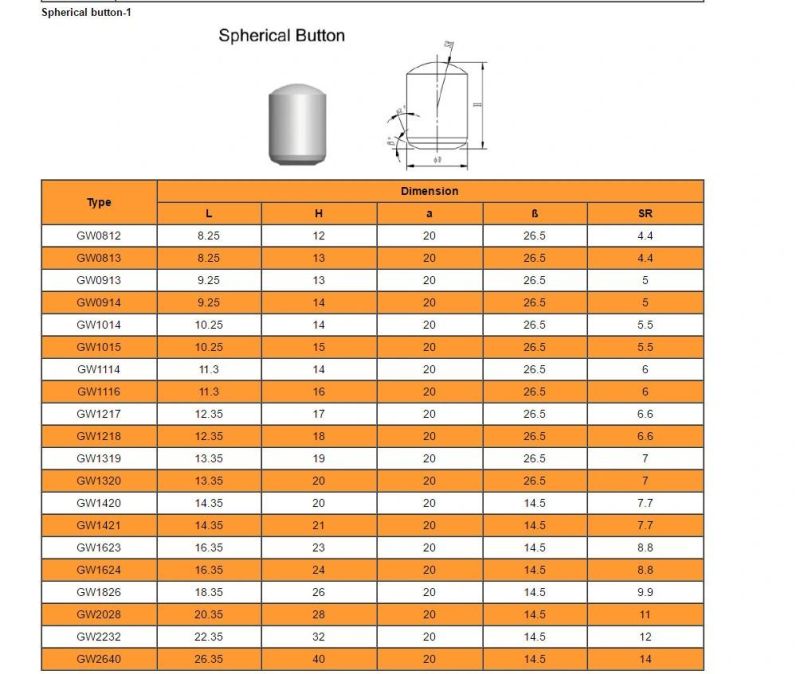

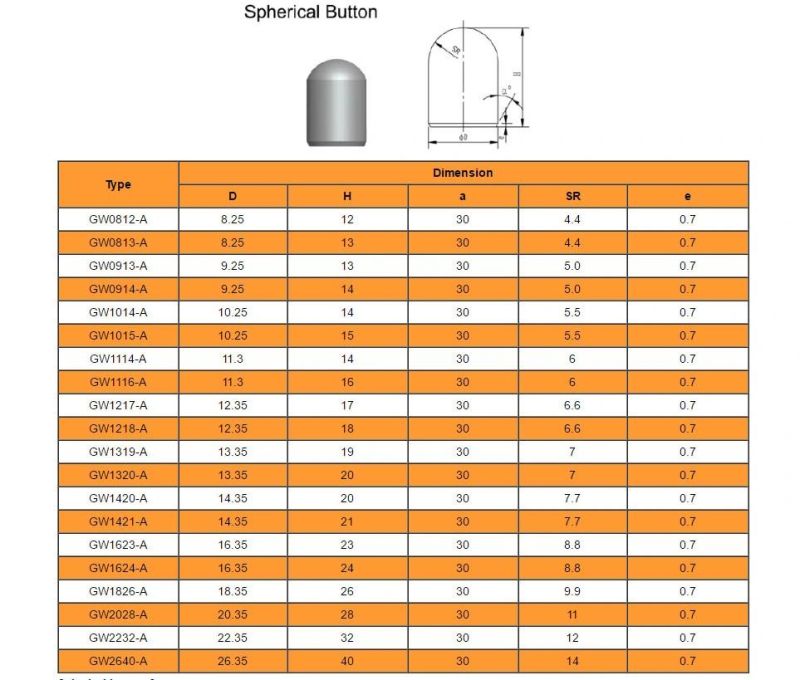

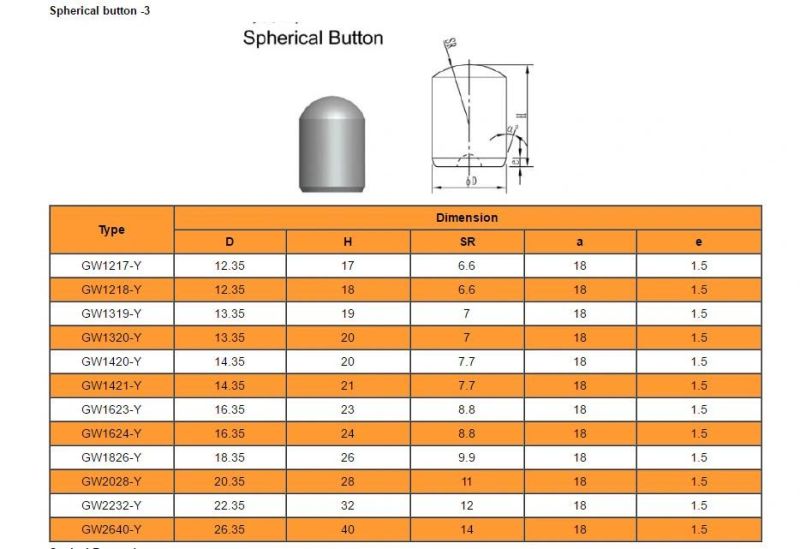

sizes are:

used for:

Other types are: