High Efficiency PF 1010 Soft Rock Impact Crusher

Henan Centbro Machinery Equipment Co., Ltd.- Type:Impact Crusher

- Motor Type:AC Motor

- Motor Power:55-75kw

- Application:Mine

- Materials:Stone

- Outlet Size:0-150mm

Base Info

- Model NO.:PF-1010

- Inlet Size:400*1080mm

- Condition:New

- Warranty:One Year

- After-sales Service:Engineer Working on The Site

- Max Feeding Size:300mm

- Weight:14t

- Transport Package:Exporting Standard

- Specification:2390*2040*2600mm

- Trademark:STM Centbro

- Origin:Zhengzhou, China

- HS Code:8474209000

- Production Capacity:30 Sets Per Month

Description

Impact Crusher can crush the large, medium and small size materials (granite, limestone, concrete ,etc.)With max feed size less than 500mm and compression strength less than 350Mpa.

Impact Crusher can crush the large, medium and small size materials (granite, limestone, concrete ,etc.)With max feed size less than 500mm and compression strength less than 350Mpa.It is widely used in metallurgy, mine, cement, chemical engineering, fire resistant materials, ceramics and other industrial sectors, as well as in the expressway construction, water conservancy project, building crushed stone, and machine-made sand process fields, etc.

I

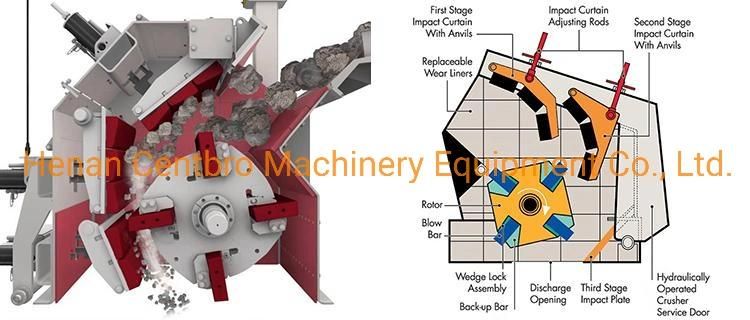

Impact crusher has two series: two-cavity and three-cavity impact crusher. It is a kind of crushing equipment using impact energy to crush material driven by motor. When the materials get into the area where the plate hammer effects, by whose high speed impact function, the crushed materials are thrown to the impact device above the rotor continuously, and then they are rebounded from the impact liner to the effect area of the blow bar to be crushed again. The materials are crushed from big-size to small-size in the impact cavity repeatedly. The process goes on until the materials are crushed to the required size and then discharged from the down part of the machine.

Impact crusher has two series: two-cavity and three-cavity impact crusher. It is a kind of crushing equipment using impact energy to crush material driven by motor. When the materials get into the area where the plate hammer effects, by whose high speed impact function, the crushed materials are thrown to the impact device above the rotor continuously, and then they are rebounded from the impact liner to the effect area of the blow bar to be crushed again. The materials are crushed from big-size to small-size in the impact cavity repeatedly. The process goes on until the materials are crushed to the required size and then discharged from the down part of the machine.Client Visit:

Certificates:

Contact:

Support:

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support :

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support :

STM Group has been largely adopting new technologies, new techniques and high-tech equipment. And STM Group also has strict and effective quality control system. We have obtained ISO9001:2000 quality system certificate.