High Output Energy Saving Magnesium Metal Making Plant

Henan Zhengzhou Mining Machinery Co., Ltd.- Application:Magnesium Production Line

- Type:Magnesium Production Equipment

- Certificate:ISO9001,ISO14000

- Design:by Professional Engineer

- Company Established:1956

- Factory Area:55000m2

Base Info

- Model NO.:Various Model

- Spare Parts:We Offer

- Installation:Under Our Engineer′s Guide

- After Sale Service:We Offer

- Price:Best Price

- Transport Package:Standard Export Packing

- Specification:ISO9001, ISO14000, CE

- Trademark:ZK

- Origin:Zhengzhou, China

- Production Capacity:Reference to The Form

Description

Basic Info.

Model NO. Various Model Spare Parts We Offer Installation Under Our Engineer′s Guide After Sale Service We Offer Price Best Price Transport Package Standard Export Packing Specification ISO9001, ISO14000, CE Trademark ZK Origin Zhengzhou, China Production Capacity Reference to The FormProduct Description

High output energy saving Magnesium Metal Making Plant

Product description:

We are a leading manufacturer of magnesium production line both at home and abroad, in the year of 2011, we signed an contract of annual output of 100000 tons of magnesium metal project with the world iron and steel giant Korean Pohang iron POSCO. We can provide plant design, equipment/spare parts supply, consultation and technical service for dolomite & magnesite calcination.

- More than 50 years experience in magnesium industry.

- Design capacity of magnesium line: 5,000-25,000 tons per year.

- Professional Process Design Engineers, Equipment Engineers, Electrical Engineers.

- Leading supplier of magnesium production line, and we take up over 90% of the market share.

Magnesium Calcination Process:

Step1: Calcining

1. Process introduction: Selecting proper dolomite (size from 10-50mm),crushing and screening after it is carried to the factory, then feed the dolomite (>20mm) to the calcination system(including preheater,rotary kiln and cooler), after calcination and cooling, then the calcined dolomite will be conveyed to the hopper.

2. Main Equipments: Jaw Crusher, Conveyor, Vibrating screen, Vertical preheater, Rotary kiln, Vertical cooler, etc.

Step2:Grinding and balling

1. Process introduction: Using jaw crusher and ferrosilicon crusher to crush and grind ferrosilicon to the size of less than 20mm, then grinding these three kinds of minerals(calcined dolomite,ferrosilicon and fluorite), after grinding, convey them to the briquetter.

2. Main equipment: Electronic batching scale, Bucket elevator, Ball mill, Screw conveyer ,FU chain conveyor, etc.

Step3:Reduction reaction and Refining

1. Process introduction: To refine the raw materials, and produce qualified products.

2. Main equipment: Reduction furnace, Refining furnace, Electronic moisture device, Wind machine, Vacuum pump, Electronic moisture device, Jet pump, Continuous casting machine, etc.

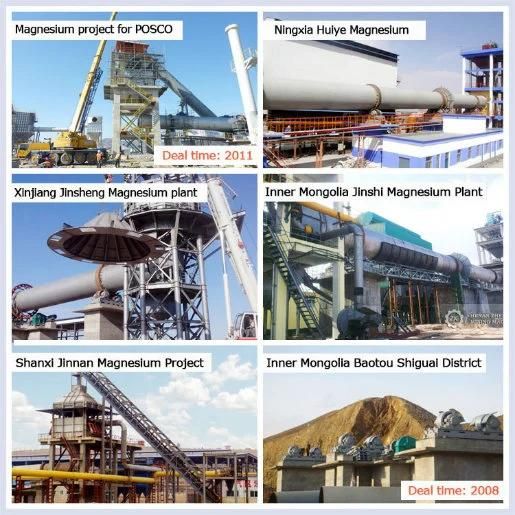

Projected Cases:

Company information:

Henan Zhengzhou Mining Machinery Co., Ltd was founded in 1956, and it is located in Wulong Industrial District in Zhengzhou which is the capital of Henan Province. It is at the junction of 310 State Road and Xingmi Road, and it is close to downtown and Xinzheng International Airport. It is very convenient in transportation.

The main products of company include: ball mill, rotary kiln, vertical preheater, cooler, crusher, metallurgical coke oven, magnetic separator, flotation machine, classifier, feeder, bucket elevator, dust collector, elevator, drier, and other equipments relate to metallurgy, cement, lime, mineral processing, refractory, chemical industry. The products of Henan Zhengzhou Mining Machinery Co., Ltd have been sold all over the country and exported to Russia, Korea, Vietnam, Malaysia, Nepal, Bangladesh, Mexico, Armenia, Africa, South America, etc

At present, Henan Zhengzhou Mining Machinery Co., Ltd is the largest and most powerful equipment supplier for magnesium production and at the same time, our company has been playing an important role for 25 years in the market.

FAQ:

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

Q: How long is the warranty of your equipment? Do you supply spare parts?

A: Our warranty period is one year generally. We can supply spare parts.

Q: Do you provide after-sale service?

A: Yes. We have a professional after sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Do you provide magnesium production line flow chart?

A: Yes. Our experienced engineers are specialized in designing process flow for various magnesium production lines

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q: Have you made the whole ore dressing lines?

A: Yes. We have made several large magnesium production line at home and abroad.