Micron Powder Grinding Mill Machine for White Stone

Shanghai Clirik Machinery Co., Ltd.- Type:Ultra Fine Grinding Mill

- Motor Type:AC Motor

- Motor Power:30KW

- Rotationl Speed:21-23r,min

- Application:Mine

- Materials:Ore, Mining, Construction

Base Info

- Model NO.:HGM

- Condition:New

- Powder Production Line Fineness:30-2500 Mesh

- Powder Production Line Color:as Request

- Powder Production Line Capacity:1-30 T,H

- Powder Production Line Warranty:1 Year

- Powder Production Line After Sales:Engineers Abroad Available

- Powder Production Line Roller No.:21-44 PCS

- Powder Production Line Ring Diameter:800-1680mm

- Powder Production Line Ring No.:3-4

- Powder Production Line Power:146.05-527kw

- Powder Production Line Input Size:20mm

- Control System:PLC

- Motor Brand:Siemens

- Transport Package:Moistureproof, Antirust, Seaworthy

- Specification:CE, SGS, ISO9001

- Trademark:clirik

- Origin:Shanghai, China

- HS Code:84742090

- Production Capacity:100 Sets Per Month

Description

Basic Info.

Model NO. HGM Condition New Powder Production Line Fineness 30-2500 Mesh Powder Production Line Color as Request Powder Production Line Capacity 1-30 T/H Powder Production Line Warranty 1 Year Powder Production Line After Sales Engineers Abroad Available Powder Production Line Roller No. 21-44 PCS Powder Production Line Ring Diameter 800-1680mm Powder Production Line Ring No. 3-4 Powder Production Line Power 146.05-527kw Powder Production Line Input Size 20mm Control System PLC Motor Brand Siemens Transport Package Moistureproof, Antirust, Seaworthy Specification CE, SGS, ISO9001 Trademark clirik Origin Shanghai, China HS Code 84742090 Production Capacity 100 Sets Per MonthProduct Description

Micron Powder Grinding Mill Machine with CE Certification

1.Grinding machine for mining, ore, chemical and construction, etc.

2.High fineness.Ultrafine grinding 325-2500mesh(47-5um) adjusted.

3.High capacity.0.5-25 t/h.High efficiency.

4.Long lifecycle of spare parts.The ring and roller are forged by special material with high utilization.

5.High safety and reliability.As no rolling bearings or screws in grinding cavity, there are no problem caused by bolts shedding or rapid wear of bearings and seal components.

6.Environment-friendly.Application of pulse bag filter & muffler greatly alleviates dust pollution and noise.

7.Advanced intelligent speed control device.Convenient adjusting, uniform particle size.

Parameter Date of Micron Powder Grinding Mill Machine with CE Certification

| Model | HGM80 | HGM90 | HGM100 | HGM125 | HGM168L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(PCS) | 18-21 | 24-29 | 28-36 | 30-44 | 30-40 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size (mm) | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 |

| Finished Size (um/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-6 (150-2000) | 100-9 (150-1500) |

| Capacity (t/h) | 0.4-4.5 | 0.6-6.5 | 1-9 | 2-16 | 3.8-30 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 14*9*10.25 | 26.3*7.5*11.9 |

| Unit: KW | HGM80 | HGM90 | HGM100 | HGM125 | HGM168L |

| Main Unit | 55-75 | 2*45 | 132 | 185-200 | 315 |

| Classifier | 18.5 | 18.5 | 30 | 37-4*15 | 5*18.5 |

| Blower | 45 | 55 | 75 | 2*45-2*55 | 2*75-2*90 |

| Crusher | 18.5 | 18.5 | 18.5 | 45 | 75 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 7.5 |

| BeltConveyor Feeder | 2.2 | 2.2 | 2.2 | 3 | 3 |

| Spiral Conveyor | 3 | 3 | 3-4 | 2*3 | 2*5.5 |

| Discharging Valve | 2*0.75 | 1*0.75 1*1.1 | 2*1.1 | 2*1.1 | 2*0.75-2*1.5 |

| Air compressor | 11 | 15 | 22 | 2*15-37 | 55 |

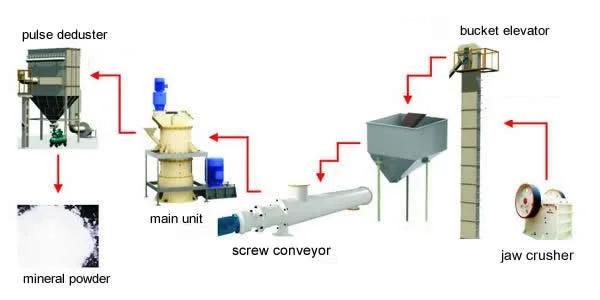

Working principle of Micron Powder Grinding Mill Machine with CE Certification

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.When the grinding mill is at work, the main bearing and each dial are driven by electromotor through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger.The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers.The high-pressure air blower constantly inhales air, airflow with crushed materials are brought to classifier whose high-speed impeller will screen the airflow:The unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector.Most of the qualified powders will fall and exit from the discharging valve at the bottom;A small proportion of the fine powders, with airflow, moves to the dust cleaner.The materials from the above two lots are sent by the conveyor to get finished powders packed.In addition, filtered clean air will be emitted from muffler in the end.

Company brief introudction:

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, all kinds of crushers from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine.Powder conveying system, etc.We have devoted into grinding field for more than 30 years, we belive only focus can be professional.We have already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our service of Micron Powder Grinding Mill Machine with CE Certification

1.One year guarantee for whole machine except for wear parts

2.24 hours technical support

3.Calling service

4.User manual available

5.Reminding for the service life of the wearing parts

6.Installation guide for clients from both China and abroad

7.Maintance and replacement service

8.Whole process trainling and guidance from our technicians

Inquiry Service of phosphate grinding mill, phosphate mills grinder, powder mill, powder making machine

Please fill in your need products and your message if you like to be contacted.Pls kindly check the following:

1.What is the raw material do you want to process?

2.What is the capacity per hour do you need?

3.What is the raw material input size?

4.What is the output size of your product?

Our Certification

Our Workshop

Our Exhibition

Our Customer Factory

We hope you can tell us these details, we will give you the best quotation, technical data and solution drawing ASAP.Your satisfaction is our greatest pursuit, we would like to sincerely for your service!We look forward to your inquiry!