High Chrome Cr26 Wear Parts Impact Crusher Blow Bars

Shanghai Duoling Watson Mining Equipment Co., Ltd.- Certification:ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:Alloy Steel

- Transport Package:Iron Frame

Base Info

- Specification:Cr26

- Origin:China

- HS Code:8474900000

- Production Capacity:10000ton Per Year

Description

NO.

chemical composition %

HRC

C

Si

Mn

Cr

Mo

Na

Cu

P

S

KmTBCr4Mo

2.5-3.5

0.5-1.0

0.5-1.0

3.5-4.5

0.3-0.5

-

-

≤0.15

≤0.10

≥55

KmTBCr9Ni5Si2

2.5-3.6

1.5-2.2

0.3-0.8

8.0-10.0

0-1.0

4.5-6.5

4.5-6.5

-

-

≥58

KmTBCr15Mo

2.8-3.5

≤1.0

0.5-1.0

13-18

0.5-3.0

0-1.0

0-1.0

≤0.10

≤0.06

≥58

KmTBCr20Mo

2.0-3.3

≤1.2

≤2.0

18-23

≤3.0

≤2.5

≤1.2

-

-

≥60

KmTBCr26

2.3-3.3

≤1.2

≤1.0

23-30

≤3.0

≤2.5

≤2.0

-

-

≥60

Cone crusher

HP100, HP200, HP300, HP400, HP500, HP4, HP5, GP100, GP200, GP300, GP550, GP11

Bowl liner, mantle

H2800, H3800, H4800, H6800, H7800, H8800, S2800, S3800, S4800, S6800

4FT.Standard, 4-1/4FT.Short head , 5-1/2FT.Standard

Features of cone crusher wear parts :

1) Material: high manganese steel:Mn13Cr2, Mn18Cr2, etc;

2) Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

Chemical composition of cone crusher wear parts

Code Elem

C

Mn

Si

Cr

Mo

P

S

ZGMn13-1

1-1.45

11-14

0.3-1

-

-

≤0.09

≤0.04

ZGMn13-2

0.9-1.35

11-14

0.3-1

-

-

≤0.09

≤0.04

ZGMn13-3

0.9-1.35

11-14

0.3-0.8

-

-

≤0.09

≤0.04

ZGMn13-4

0.9-1.3

11-14

0.3-0.8

1.5-2

-

≤0.09

≤0.04

ZGMn13-5

0.75-1.3

11-14

0.3-1

-

0.9-1.2

≤0.09

≤0.04

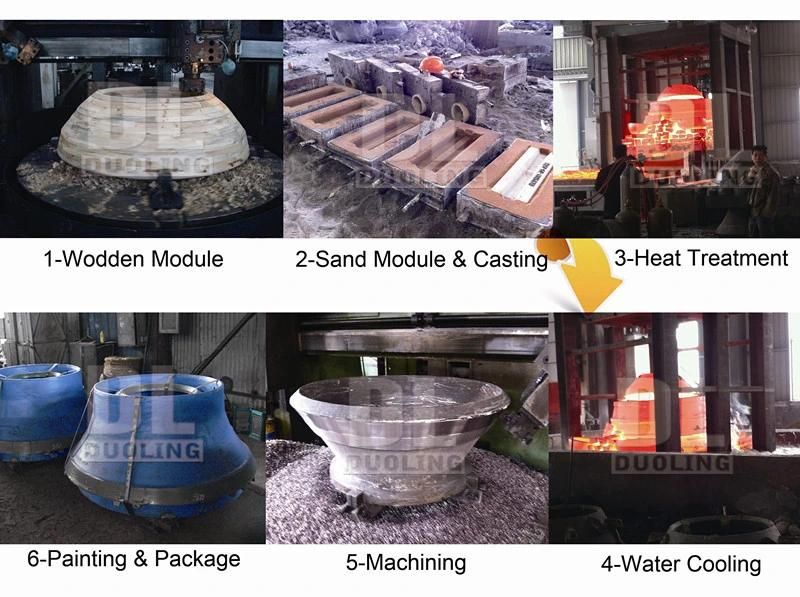

Production Process of Crusher Wear Parts