Wet and Dry Silica Quartz Stone Power Ball Mill

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:22KW

- Rotationl Speed:23-25r,min

- Application:Construction

- Materials:Iron

Base Info

- Condition:New

- Mining Object:Metallic and Non-Metallic Ore Excavator

- Capacity:80-120t

- Price:Factory Price

- Color:Red, Yellow

- Drawing:CAD Drawing

- Installation:Engineer Oversea Service

- Spare Parts:One Year for Free

- Certificate:Ce ISO

- After-Sale Service:All Using Time

- Original Place:China

- Transport Package:Export Standard Container

- Specification:International Standard

- Trademark:HengXing

- Origin:Henan Province China

- HS Code:8474202000

- Production Capacity:1000sets,Year

Description

Basic Info.

Condition New Mining Object Metallic and Non-Metallic Ore Excavator Capacity 80-120t Price Factory Price Color Red, Yellow Drawing CAD Drawing Installation Engineer Oversea Service Spare Parts One Year for Free Certificate Ce ISO After-Sale Service All Using Time Original Place China Transport Package Export Standard Container Specification International Standard Trademark HengXing Origin Henan Province China HS Code 8474202000 Production Capacity 1000sets/YearProduct Description

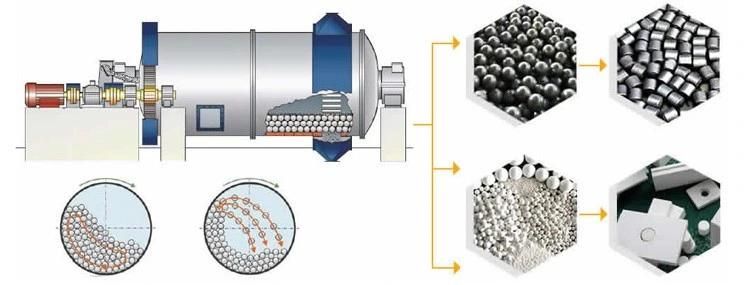

Wet And Dry Silica Quartz Stone Power Ball Mill Application of Silica Grinding Mill/Quartz Ball Mill:As a piece of mineral processing equipment, a Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill is widely used in beneficiation, building material and chemical industries. Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill is suitable for dry-type ore grinding and wet-type ore grinding. According to different discharging methods, ball mills fall into grate ball mill and overflow ball mill.

Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill is a mineral processing machine for milling the materials into powders after they are crushed. Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries. Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill could carry out dry and wet millings on different materials.

Working Principle of Silica Grinding Mill/Quartz Ball Mill:

Our Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill is of horizontal, cylindrical and tubular structure. It comes with two cabins and is a grate ball mill. The materials are evenly fed through the charging device to first warehouse where there are step scales boards, corrugated scale boards and different specifications of steel balls. When the cylinder rotates, the centrifugal force produced causes the steel balls to impact and grind the materials in the Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill. The materials are then lead to the second cabin for further milling until they turn into powders and are discharged from the outlet.

Ways of Improving Productivity of ball mill:

In addition to manufacturing Silica Grinding Mill/Quartz Ball Mill/Feldspar Grinding Mill, we also carry our research on improving its productivity. Generally speaking, the productivity of ball mill can be improved by:

1. Adding fine crusher before the ball mill.

2. Improving grinding system to achieve better grinding efficiency.

3. Adding powder concentrator.

Technical Parameter of the Wet And Dry Silica Quartz Stone Power Ball Mill

| Model | Rotational speed (r/min) | Ball load (t) | Feeding size (mm) | Output size (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| 900× 1800 | 36-38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900× 3000 | 36 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200× 2400 | 36 | 3 | ≤ 25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200× 3000 | 36 | 3.5 | ≤ 25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200× 4500 | 32.4 | 5 | ≤ 25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500× 3000 | 29.7 | 7.5 | ≤ 25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500× 4500 | 27 | 11 | ≤ 25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500× 5700 | 28 | 12 | ≤ 25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830× 3000 | 25.4 | 11 | ≤ 25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830× 4500 | 25.4 | 15 | ≤ 25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830× 6400 | 24.1 | 21 | ≤ 25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| 1830× 7000 | 24.1 | 23 | ≤ 25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| 2100× 3000 | 23.7 | 15 | ≤ 25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| 2100× 4500 | 23.7 | 24 | ≤ 25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100× 7000 | 23.7 | 26 | ≤ 25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200× 4500 | 21.5 | 27 | ≤ 25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| 2200× 6500 | 21.7 | 35 | ≤ 25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| 2200× 7000 | 21.7 | 35 | ≤ 25 | 0.074-0.4 | 15-28 | 380 | 54 |

| 2200× 7500 | 21.7 | 35 | ≤ 25 | 0.074-0.4 | 15-30 | 380 | 56 |

| 2400× 4500 | 21 | 30 | ≤ 25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| 2700× 4000 | 20.7 | 40 | ≤ 25 | 0.074-0.4 | 12-80 | 400 | 94 |

| 2700× 4500 | 20.7 | 48 | ≤ 25 | 0.074-0.4 | 12-90 | 430 | 102 |

| 3200× 4500 | 18 | 65 | ≤ 25 | 0.074-0.4 | Depending on technological conditions | 800 | 137 |

contact: Sara