High Energy Ball Mill with 8% Discount Factory Price

Henan Hongke Heavy Machinery Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:18.5KW

- Rotationl Speed:42 R,Min

- Application:Cement, Refractories, Chemicals, Fertilizer

- Materials:Optional

Base Info

- Model NO.:900*1800

- Condition:New

- Warranty:3 Years

- After-sales Service:Life Long Time

- Model No.:Ball Mill

- Feeding Size(mm):<=20

- Output Size(mm):0.075-0.89

- Capacity(T/H):0.65-2

- Motor Power(Kw):18.5

- Weight(Kg):3.6

- Installation:We Send Engineers

- Delivery Detail:Within 10 Days After The Contract

- Production:30 Sets, Month

- Transport Package:Wooden Packing or as Clients Required

- Specification:Reference as the Form

- Trademark:HongKe

- Origin:Zhengzhou, Henan, China

- HS Code:84742090

- Production Capacity:30 Sets,Month

Description

Basic Info.

Model NO. 900*1800 Condition New Warranty 3 Years After-sales Service Life Long Time Model No. Ball Mill Feeding Size(mm) <=20 Output Size(mm) 0.075-0.89 Capacity(T/H) 0.65-2 Motor Power(Kw) 18.5 Weight(Kg) 3.6 Installation We Send Engineers Delivery Detail Within 10 Days After The Contract Production 30 Sets/ Month Transport Package Wooden Packing or as Clients Required Specification Reference as the Form Trademark HongKe Origin Zhengzhou, Henan, China HS Code 84742090 Production Capacity 30 Sets/MonthProduct Description

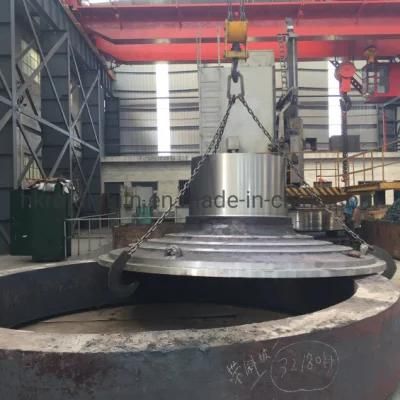

2.4*13m Wet and Dry Ball Mill Grinding for Sale

Ball mill is a key equipment for regrinding, it is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. The ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

Features of Ball Mill

1.This type of ball mill is a kind of traditional ball mill, with rolling bearings (Babbit metal bearing bushing seat)

2. Simple structure, and split installation.

3. It is easy to lift it while installing and maintaining.

4. Its feeders are classified into two types: combined feeder and cylinder feeder.

Working principle of Ball Mill Grinding

1. This ball mill is horizontal type and tubular running device, has two warehouses.

2. This machine is grid type and its outside runs along gear.

3. The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device.

Notes for ordering of Ball Mill

1.While placing your order, please specify the model, quantity, and the rotating direction as well.

2.Since the ball mills are classified into two types: grate ball mill and overflow ball mill, please specify the type.

Technical of Ball Mill

| Model | Rotary Speed (r/min) | The feeding size (mm) | The final Size (mm) | Capacity (t/h) | Main Motor (kw) | Weight (t) |

| 900×1800 | 38 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.9 | 3.6 |

| 900×3000 | 38 | ≤ 20 | 0.075-0.89 | 1.1-4.8 | 22 | 4.6 |

| 1200×2400 | 32 | ≤ 25 | 0.075-0.6 | 1.5-4.8 | 45 | 12.5 |

| 1200×2800 | 35 | ≤ 25 | 0.074-0.4 | 1.2-3.7 | 30 | 11.5 |

| 1200×3000 | 32 | ≤ 25 | 0.074-0.4 | 1.6-5 | 45 | 12.8 |

| 1200×4500 | 32 | ≤ 25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500×3000 | 27 | ≤ 25 | 0.074-0.4 | 2-5 | 75 | 17 |

| 1500×4500 | 27 | ≤ 25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500×5700 | 27 | ≤ 25 | 0.074-0.4 | 3.5-6 | 110 | 24.7 |

| 1830×3000 | 24 | ≤ 25 | 0.074-0.4 | 4-10 | 180 | 28 |

| 1830×6400 | 24 | ≤ 25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| 1830×7000 | 24 | ≤ 25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| 2200×5500 | 21 | ≤ 25 | 0.074-0.4 | 10-22 | 370 | 48.5 |

| 2200×6500 | 21 | ≤ 25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| 2200×7000 | 21 | ≤ 25 | 0.074-0.4 | 8-36 | 380 | 50 |

| 2200×7500 | 21 | ≤ 25 | 0.074-0.4 | 16-29 | 475 | 56 |

| 2100×2700 | 24 | ≤ 20 | 0.074-0.4 | 3.5-25 | 150 | 33 |

| 2100×3500 | 24 | ≤ 25 | 0.074-0.4 | 4.5-33 | 180 | 37 |