High Quality DTH Drill Bit CIR MD-Mc175 Bit for Mining

WUHAN KINGDRILLING DIAMOND CO., LTD.- Certification:ISO 9001:2000, SGS

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Forging

- Material:Carbon Steel

- Customized:Customized

Base Info

- Model NO.:MD-MC175

- Quantity:Small Quantity Is Acceptable

- Usage:Pneumatic, Coal, Water Well, Mining

- Transport Package:Wooden Case

- Trademark:MING

- Origin:China

- HS Code:8207199000

- Production Capacity:20000PCS,Year

Description

Basic Info.

Model NO. MD-MC175 Quantity Small Quantity Is Acceptable Usage Pneumatic, Coal, Water Well, Mining Transport Package Wooden Case Trademark MING Origin China HS Code 8207199000 Production Capacity 20000PCS/YearProduct Description

High Quality DTH Mining Drill Bit CIR MD-MC175 Bits for Mining

KINGDRILLING variety of Down the Hole (DTH) bits is manufactured using high quality materials to provide you with a fine balance between penetration capability and bit life.

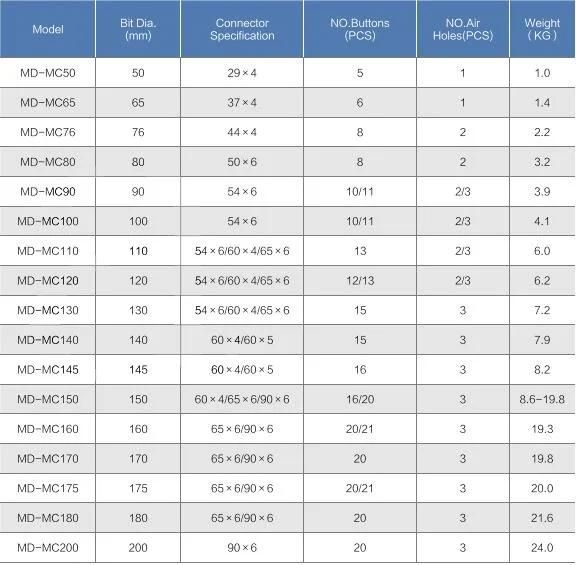

Shank types: CIR90, CIR100, CIR110, etc.

DTH hammer bits hole diameter: 3'', 4'', 5'', 6'', 8''(85mm-305mm).

How to choose the suitable head face of the DTH drill bit?

- Concave:

- Convex:

- Flat:

Our Advantages as below:

- High quality steels materials. Steel is from TIMKEN and Tungsten carbide are YK05, or T6 from Element Six in Germany

- Kingdrilling DTH tools are forged by advanced electron-hydraulic forging hammer.

- Advanced heat-treatment equipment: multipurpose furnace heat treatment.

- Completed moulding (tooling ) departments with many molds available.

- Professional R&D team,completed quality system.

- Strict Quality-Check Systems.

FAQ:

1. How to order the products?

A: Please send the inquiry with detail item description or with Model number.

2. How about the common packing?

A: If there is no special packing demand, we will take it as our normal packing. First in small carton, and then put in the bigger carton together to make sure goods completed.

3. Can I expect a quality products?

A: Yes. mature production technology ensuring the quality satisfy international request.

4. How to check the product are the exact one you want?

A: If possible, please attach one reference picture to avoid any misunderstanding or any links from our website for a better understanding.

5. How to control quality?

A: We have our own experienced QC team,there will be strict inspection and testing for each order before shipping out.

6. Fast delivery time:

A: Usually it takes 25 days for production.only 3 or 5 days if we have stock of your request size.

7. Shipping way:

A: Sample order: we suggest Courier express delivery such as DHL/UPS/TNT/FEDEX or by air

Bulk order: by air or by sea we suggest.

8. Competitive price:

A:KINGDRILLING factory can supply you the lowest price due to direct sale to customers without distributor!

Product Application:

Transport:

Package and Delivery:

Packed by Carton or Wooden cases.

Delivery:

- Goods in stock can be delivered within 5 days.

- DTH Bits production time is about 15 days.

- DTH Hammer product time is about 30 days.