Rotary Drum Dryer for Bentonite Material in Drying System

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd.- Model:Φ2.2×20

- Object:Limestone,Gypsum,Sand,Bentonitesilica,Ore,

- Drum diameter:Φ800mm

- Certification:ISO9001:2000, CE

- Energy Saving:Energy Saving

- Warranty:1 Year

Base Info

- Model NO.:1.8x14m

- Customized:Customized

- Condition:New

- Application:Ore,Mineral Dressing,Building Material,Metallurgy,

- Operation Training:Provided

- Quality:High Reputation

- Trademark:ZONEDING

- Origin:China

- HS Code:8419399090

- Production Capacity:1-100t,H

Description

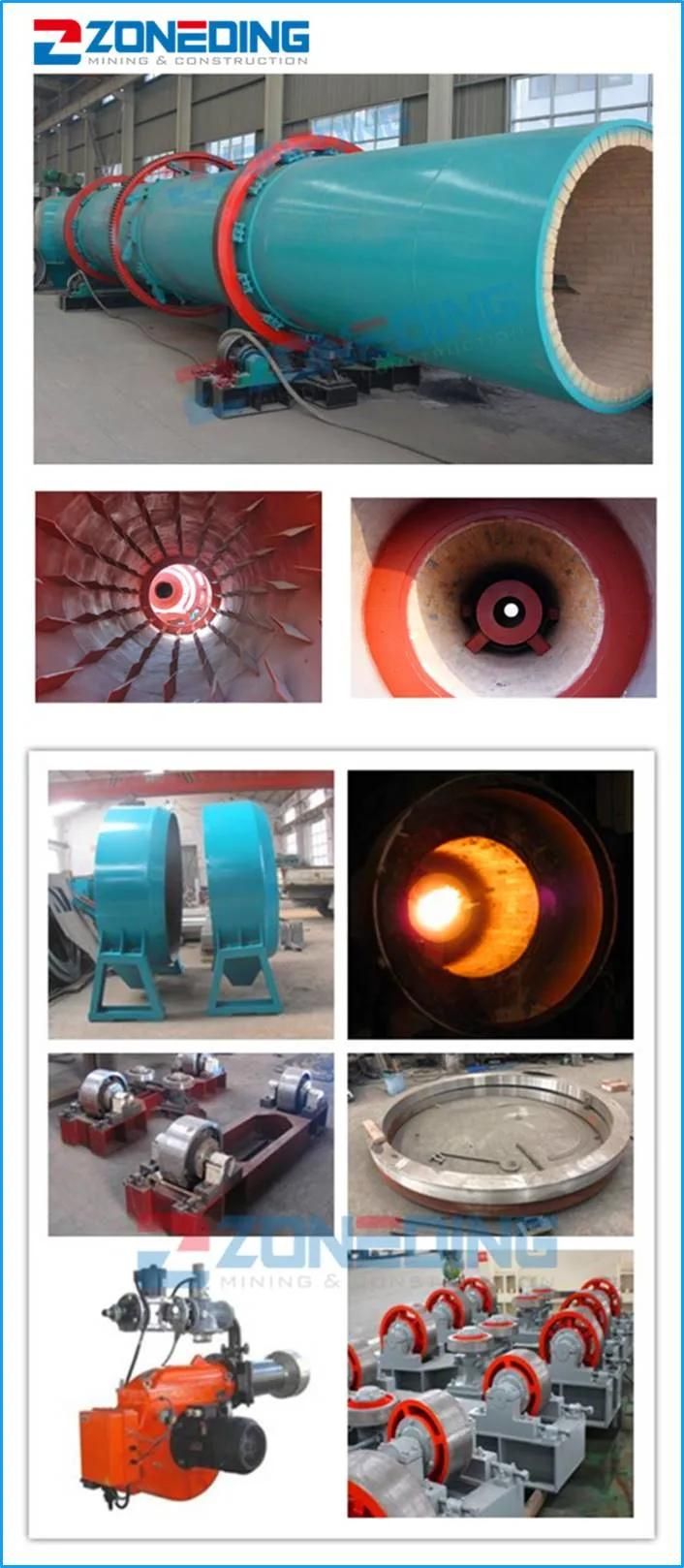

Structure:

The rotary dryer is mainly composed of a frame, a heat supply source, a loading machine, a feeding machine, a rotary drum, a material crushing device, a discharging machine, an induced draft fan, a discharger, and a power distribution cabinet. Widely used in sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, refractory materials, building materials, and other industries. The equipment is simple and reliable to operate, so it is widely used.

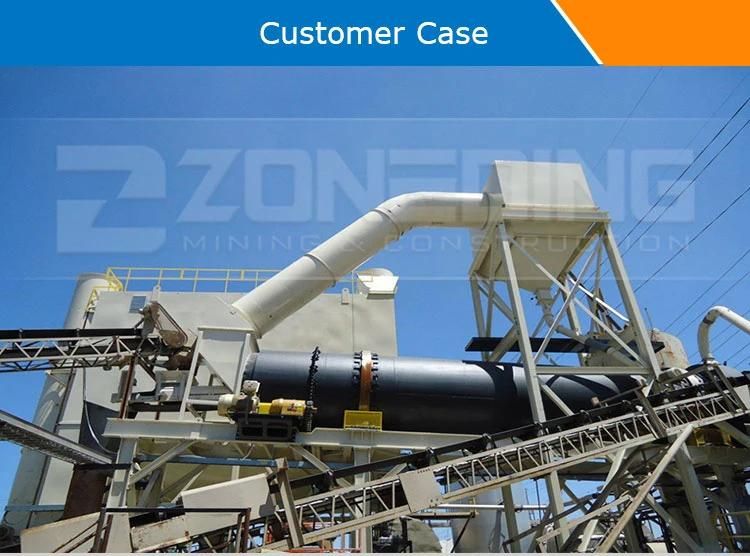

Rotary Drying production line was installed in Russia in 2017

Capacity: 15 t/h Raw material: sand, sludge

Main Equipment: Vibrating Feeder, Jaw Crusher, Impact Crusher, Vibrating Screen, Belt Conveyor.

Rotary Drying Plant in Philippines

Rotary Drying Plant in Philippines

FAQ:

1.How to choose dryer equipment?

A: At first, please inform us what kind of material you need to dry.

Second, you should inform us how much output you need per hour.

Third, what kind of heat source you have(Electric heating/oil furnace/gas furnace/coal furnace/stream)

Finally, we need to know the moisture before drying and after drying.

2.Can you provide plant layout?

A: Yes, we can provide.