High Quality Factory Direct Supply Cement Ball Mill Price

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Ore Grinder

- Application:Stone, Mining Ore, Gold, Copper Ect.

- Color:as Your Require

- Price:Negotiable

- Pre-Service:Free

- Installation:Under Our Engineer Guide

Base Info

- Model NO.:MG

- After-Service:for Whole Using Life

- Capacity(T/H):0.3-155

- Mining Object:Ball Mill

- Transport Package:Standard Container

- Specification:ISO, CE, SGS

- Trademark:HC

- Origin:Gongyi City, Henan Province, China

- HS Code:8474100000

- Production Capacity:150 Set,Year

Description

Basic Info.

Model NO. MG After-Service for Whole Using Life Capacity(T/H) 0.3-155 Mining Object Ball Mill Transport Package Standard Container Specification ISO, CE, SGS Trademark HC Origin Gongyi City, Henan Province, China HS Code 8474100000 Production Capacity 150 Set/YearProduct Description

High-quality Factory direct supply Cement ball mill priceTypes of Ball Mill Introduction:

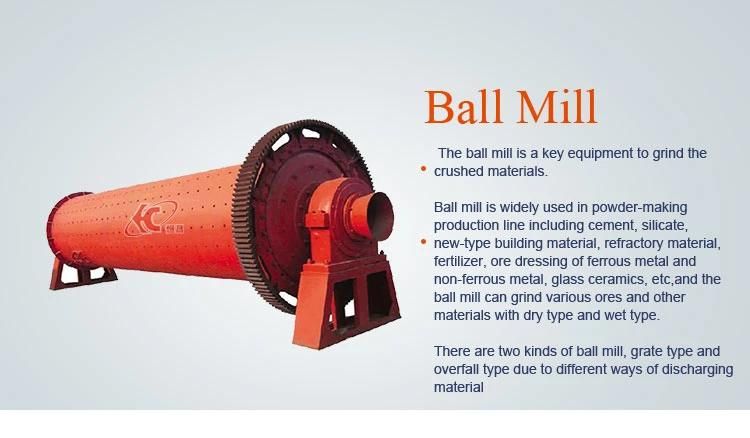

Ball Mill is a key equipment to grind all kinds of ores and other materials. Which is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc

*Cement ball mill

Ball Mill consists of feed&discharge parts, rotary shell, transmission part, and other major components. The hollow shaft is with steel parts, the lining is removable. Rotary gear adopts casting hobbing, and the tube body is with resisting liner.

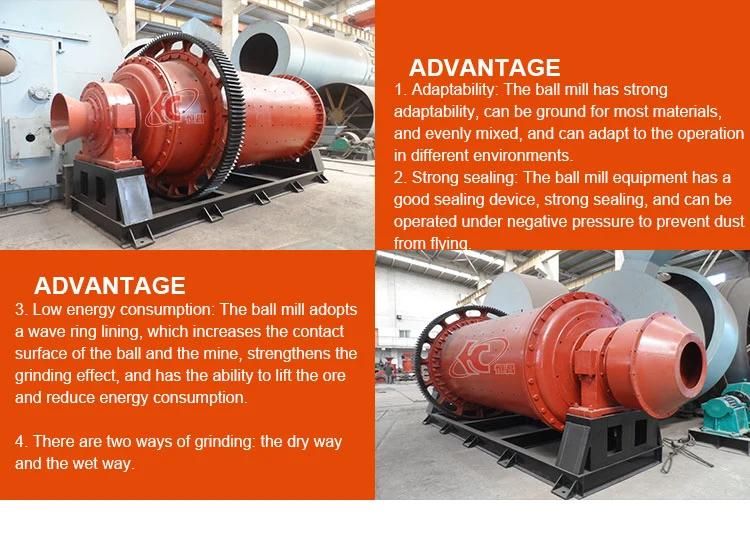

Ball Mill Advantages

1. High efficiency of grinding

2. Low failure rate

3. Prosper design

4. Convenient usage.

*Working Principle:

The ball mill is a horizontal cylindrical rotation device, driven by a brim gearwheel. There are two chambers and a grid of ball mill. The material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The ball mill shell rotates to generate electricity, and this force brings the ball to a certain height and then balls drop down by gravity, the impact is the grinding force to the material. After the primary grinding, materials go into the second chamber through a segregate screen. In the ball mill the second chamber, there are flat liners and steel balls. After the secondary grinding, the material is discharged from the discharging mouth. Then the whole grinding process is ended.

Model | Cylinder speed(r/min) | Ball capacity (t) | Material-in size(mm) | Material-out size(mm) | Capacity(t/h) | Motor power(kW) | Weight(T) |

Ø900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 15 | 4.2 |

Ø900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Ø1200×2400 | 37 | 3.8 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 11.5 |

Ø1200×3000 | 37 | 5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Ø1200×4500 | 37 | 6.6 | ≤25 | 0.074-0.4 | 1.6-5.8 | 45 | 13.8 |

Ø1500×3000 | 29.7 | 8 | ≤25 | 0.074-0.4 | 2-5 | 75 | 16 |

Ø1500×4500 | 29.7 | 12.5 | ≤25 | 0.074-0.4 | 3-6 | 90 | 22 |

Ø1500×5700 | 29.7 | 15 | ≤25 | 0.074-0.4 | 3.5-6 | 110 | 24.7 |

Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

Ø1830×4500 | 25 | 15.8 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Ø1830×6400 | 24.1 | 23 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 36.5 |

Ø1830×7000 | 24.1 | 24 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 39 |

Ø2100×3000 | 24.6 | 20 | ≤25 | 0.074-0.4 | 7.5-3.6 | 180 | 40 |

Ø2100×4500 | 24.6 | 22.5 | ≤25 | 0.074-0.4 | 7.5-40 | 210 | 48 |

Ø2200×6500 | 21.7 | 25 | ≤25 | 0.074-0.4 | 10-12 | 380 | 52 |

Ø2200×7000 | 21.7 | 28 | ≤25 | 0.06-0.08 | 10-14 | 380 | 54 |

Ø2200×7500 | 21.7 | 29 | ≤25 | <0.08 | 12-14 | 380 | 56 |