10-30 Tph Quartz Rock Gold Processing Plant in PNG

Ganzhou Gelin Mining Machinery Co., Ltd.- Type:Mineral Washing & Screening

- Voltage:380V

- Weight:5T

- Material:Steel,Fiberglass

- Certification:ISO9001:2008, CE

- Energy Saving:Energy Saving

Base Info

- Model NO.:Rock gold processing plant

- Warranty:2 Years

- Color:Customized

- Customized:Customized

- Condition:New

- After-sales Service:Engineer Guidance,Video Guidance

- Use to Separate:Cassiterite Tungsten Magnetic Ore

- Transport Package:Export Packing Standard

- Trademark:Gelin

- Origin:China

- Production Capacity:100 Sets Per Month

Description

Feed OpeningMax. Feeding Size Adjusting Range Of Capacity Rotation Speed Of Motor Power Total Weight Dimensions Discharge Opening Eccentric Shaft (mm) (mm) (mm) (t/h) (r/min) (KW) (Ton) (mm) PE-200*300 200*300 180 15-50 2-6 260 7.5 1 910*750*990 PE-200*350 200*350 180 18-70 3-10 260 11 1.3 1000*870*990 PE-250*400 250*400 210 20-60 5-20 300 15 2.8 1300*1090*1270 PE-400*600 400*600 340 40-100 16-60 275 30 7 1730*1730*1630 PE-500*750 500*750 425 40-110 275 55 12 1980*2080*1870 PE-600*900 600*900 500 75-200 60-200 250 75 20 2290*2290*2400 PE-750*1060 750*1060 630 80-140 115-330 250 110 29 2660*2430*2800 PE-870*1060 870*1060 660 200-260 290-336 250 110 31.5 2810*2430*2800 PE-900*1060 900*1060 685 230-290 160-400 250 110 33 2870*2420*2940 PE-900*1200 900*1200 750 95-165 220-450 200 110 52 3380*2870*3330 PE-1000*1200 1000*1200 850 195-265 315-500 200 110 55 3480*3876*3330 PE-1200*1500 1200*1500 1020 150-300 400-800 180 160 100.9 4200*3300*3500 PEX-150*750 150*750 120 18-48 8-25 320 15 3.8 1200*1530*1060 PEX-250*750 250*750 210 25-60 13-35 330 30 5.5 1380*1750*1540 PEX-250*1000 250*1000 210 25-60 16-52 330 37 7 1560*1950*1390 PEX-250*1200 250*1200 210 25-60 20-61 330 45 8.5 2140*1660*1500 PEX-300*1300 300*1300 250 20-90 16-105 300 75 11 2720*1950*1600

3).Ball Mill

Description

6s-7.66s-4.08 6s-1.95 6s-0.5 Deck type Coarse ore deck Fine sand deck Slime deck Benefication Area(m2) 7.6 7.6 7.6 4.08 1.95 0.5 Deck size Length(mm) 4450 4450 4450 3000 2100 1100 Transmission end width (mm) 1855 1855 1855 1320 1050 500 Concentrate end width (mm) 1546 1546 1546 110 850 430 Maximum feeding size(mm) 2 0.5 0.15 Sand -2 Slime-0.1 Sand -2 Slime-0.074 Sand -2 Slime-0.074 Feeding amount 0.8-1.5ton/h 0.8-1.5ton/h 0.8-1.5ton/h 0.4-1.5t/h 0.3-0.8t/h 0.05-0.2t/h Feeding density(%) 25-30 20-25 15-25 10-30 Stroke(mm) 16-22 11-16 8-16 6-30 12-28 9-17 Frequency(F) 45-220 53-250 60-280 210-320 250-450 280-460 Water added 1-3t/h 1-3t/h 1-3t/h 0.4-2t/h 0.2-1t/h 0.1-0.5t/h Transverse slope of deck 2°30-4°30 1°30-3°30 1°-2° 0-10° 0-8° 0-10° Longitudinal slope of deck 1.4 0.92 --- --- --- --- Cross-section shape of deck rectangular saw-tooth triangle --- --- --- Motor power(kw) 1.1 0.55 Transmission mechanism Eccentric linkage

Our distinctive products include Shaking table, Jig, Spiral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, Feeder, Classifier, ore washing machine and lab equipment etc. Our machines are popular in separating gold, copper, manganese, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite, etc.

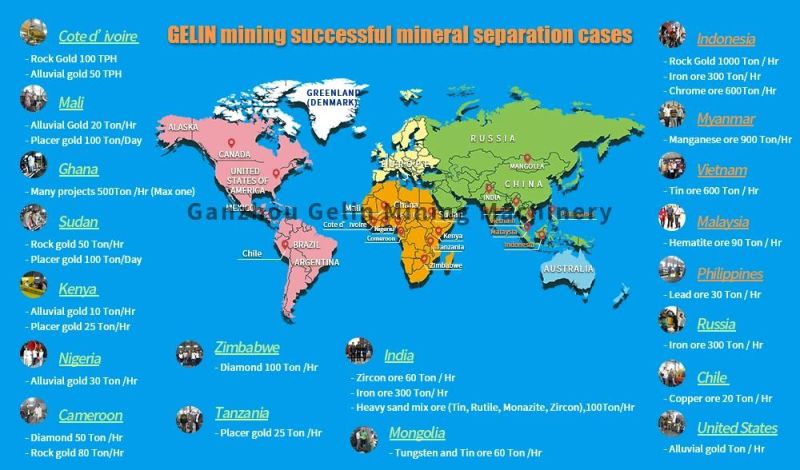

Our products are sold to more than 28 provinces/cities in China and are exported to Russia, Africa, India, the Middle East, the Philippines, Mongolia, Sudan, Kazakhstan, Brazil, America, Canada and Australia. We have won high reputations from all of our clients for our machines and services.

Besides the above mentioned products, we can also design and manufacture many kinds of special mining machines and automatic processing lines according to the requests of customers. If you are in need of detailed information, please inform us. We will provide you with total solutions according to your specific requirements in time.

7.GELIN Services

--- PRE-SALE SERVICE ---

1.Based on clients' request and budget, GELIN experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to you for testing by courier, or, the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients' demands.

--- AFTER-SALE SERVICE ---

1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION ---

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

8.Certificate

9.Customer Visiting

10.FAQ

10.FAQ

Q: How big is your factory?

A: In tolal 6 work shops17,000m², office 2500 m², 110 workers.Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and assistance.

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the reasonable flowchart, suitable solution and equipments selection. etc.Q: How long is the warrenty of your equipments? Does your company supply the spare parts?

3).Ball Mill

Description

6s-7.6

5.Packing & Delivery

6.About Us

Our distinctive products include Shaking table, Jig, Spiral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, Feeder, Classifier, ore washing machine and lab equipment etc. Our machines are popular in separating gold, copper, manganese, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite, etc.

Our products are sold to more than 28 provinces/cities in China and are exported to Russia, Africa, India, the Middle East, the Philippines, Mongolia, Sudan, Kazakhstan, Brazil, America, Canada and Australia. We have won high reputations from all of our clients for our machines and services.

Besides the above mentioned products, we can also design and manufacture many kinds of special mining machines and automatic processing lines according to the requests of customers. If you are in need of detailed information, please inform us. We will provide you with total solutions according to your specific requirements in time.

7.GELIN Services

--- PRE-SALE SERVICE ---

1.Based on clients' request and budget, GELIN experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to you for testing by courier, or, the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients' demands.

--- AFTER-SALE SERVICE ---

1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION ---

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

8.Certificate

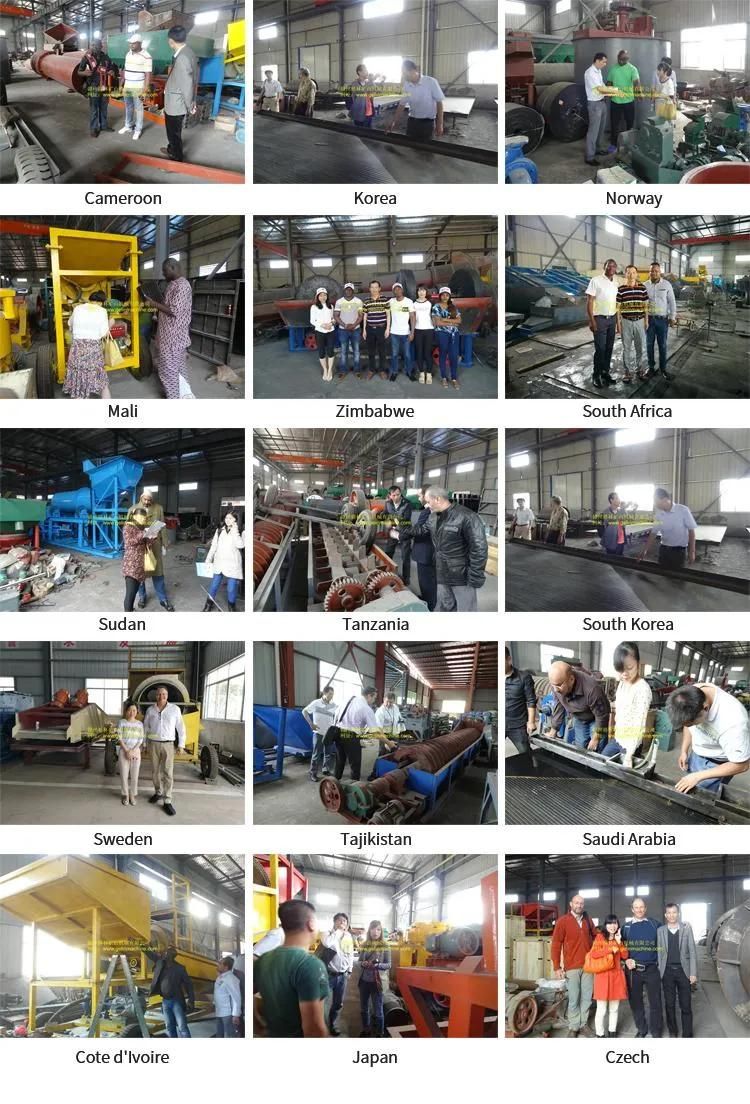

9.Customer Visiting

10.FAQ

10.FAQQ: How big is your factory?

A: In tolal 6 work shops17,000m², office 2500 m², 110 workers.

Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and assistance.

A:1). What type is the mining? Is it rock stone? or it is sand?

2). If rock stone,What is the general particle size(mm) of the raw ore?

3). What is the handling capacity(tons per hour) you plan to work with?

4).What is the elements of the raw ore? How much percent % of each minerals?

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the reasonable flowchart, suitable solution and equipments selection. etc.