Ztic Casting Steel Hammer for Hammer Crusher

Luoyang Zhongtai Industries Co., Ltd.- After-sales Service:Online Service

- Warranty:3 Months

- Material:High Chrome Crusher Hammer

- Control:Spectrometer Chemical Analysis and Control While P

- Molding Process:Water-Glass Sand Casting or Lost Form Casting

- Melting Facility:Medium Frequency Electric Furnace

Base Info

- Model NO.:custom

- Heat Treatment:Anneal, Quenching, Tempering

- Testing:Hardness, Flaw Detector Test

- Certificate:ISO9001~2008 Passed; Bureau Veritas

- Quality Guarantee:One Year Against Manufacturing Defeat

- Transport Package:Simple Packing

- Specification:custom

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:3000PCS,Year

Description

Overview

High Chrome Crusher Hammer

Material

Cr20Mn2,Cr26Mn2

Control

Spectrometer chemical analysis and control while producing

Molding Process

Water-glass sand casting or lost form casting

Melting facility

Medium frequency electric furnace

Heat Treatment

Anneal, quenching, tempering

Quality Guarantee

One year against manufacturing defeat

Testing

Hardness, flaw detector test

Certificate

ISO9001~2008 Passed; BUREAU VERITAS

2.High Manganese Hammer

The high Mn hammer head serious product make by our company ,while producing:

use the molding cold iron in the working part in order to increase the compactness of working part.

Use the refining techniques of furnace bottom blowing argon to quick-wear part. We use diversified qualitative change to increase grain boundary strength.

Use diversified inoculation to refined grain.

These High manganese little hammer for clinker crusheringinduce the hammer made by our company with higher wear resistant safety and reliability nature. Our customers are satisfied with our hammer, and our goods are exported to serious countries.

GENERAL DESCRIPTION

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

We increase crusher availability through:

? Increased wear life

? Less on-going wear part maintenance

? Designs and tools for quicker change out

Hammer crusher wearparts:

Hammer crusher wearparts.

We produce Hammers in One and Two-Piece styles, Grates, Breaker Blocks, Side Liners, Breaker Bar Sleeves, Rotor Hubs, Complete Rotor Assemblies, Top Cover Liners and Throat Collars.

?Grates

? Breaker Blocks

? Side Liners

? Breaker Bar Sleeves

? Rotor Hubs

? Complete Rotor Assemblies

? Top Cover Liners

? Throat Collars

Company Profile

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

High Chrome Crusher Hammer

Material

Cr20Mn2,Cr26Mn2

Control

Spectrometer chemical analysis and control while producing

Molding Process

Water-glass sand casting or lost form casting

Melting facility

Medium frequency electric furnace

Heat Treatment

Anneal, quenching, tempering

Quality Guarantee

One year against manufacturing defeat

Testing

Hardness, flaw detector test

Certificate

ISO9001~2008 Passed; BUREAU VERITAS

2.High Manganese Hammer

The high Mn hammer head serious product make by our company ,while producing:

use the molding cold iron in the working part in order to increase the compactness of working part.

Use the refining techniques of furnace bottom blowing argon to quick-wear part. We use diversified qualitative change to increase grain boundary strength.

Use diversified inoculation to refined grain.

These High manganese little hammer for clinker crusheringinduce the hammer made by our company with higher wear resistant safety and reliability nature. Our customers are satisfied with our hammer, and our goods are exported to serious countries.

GENERAL DESCRIPTION

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

We increase crusher availability through:

? Increased wear life

? Less on-going wear part maintenance

? Designs and tools for quicker change out

Hammer crusher wearparts:

Hammer crusher wearparts.

We produce Hammers in One and Two-Piece styles, Grates, Breaker Blocks, Side Liners, Breaker Bar Sleeves, Rotor Hubs, Complete Rotor Assemblies, Top Cover Liners and Throat Collars.

?Grates

? Breaker Blocks

? Side Liners

? Breaker Bar Sleeves

? Rotor Hubs

? Complete Rotor Assemblies

? Top Cover Liners

? Throat Collars

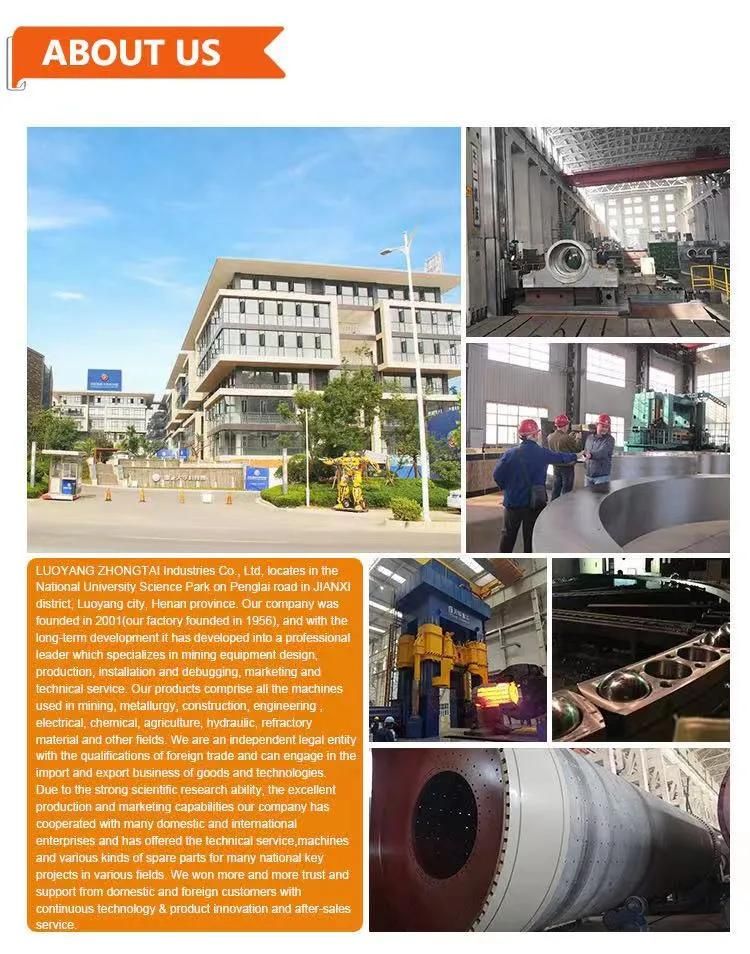

Company Profile

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.