Abrasion Resistance and Impact Resistance Material Buffering Electric Buffer Drum Tank

X-Ing Linear Actuator Co., Ltd.- Type:Vibrating Conveyor

- Structure:Roller Conveyor

- Material:Aluminium

- Material Feature:Heat Resistant

- Certification:ISO9001:2008, SGS

- Energy Saving:Energy Saving

Base Info

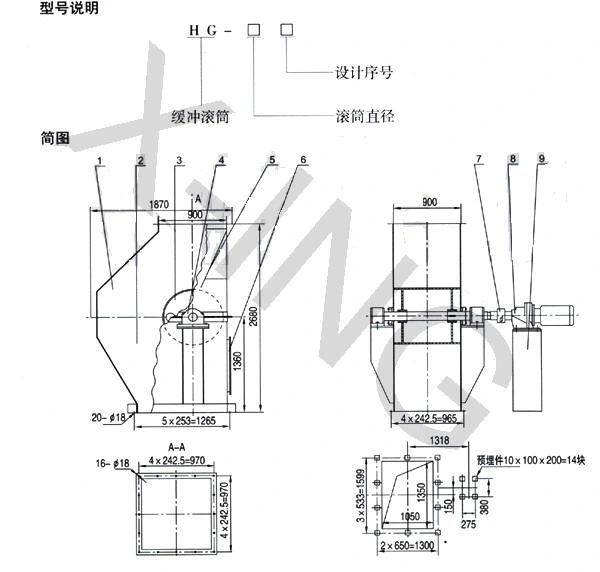

- Model NO.:HG-

- Warranty:1 Year

- Color:Blue

- Customized:Customized

- Condition:New

- Transport Package:Carton

- Specification:As per drawing

- Trademark:X-ING

- Origin:China

- HS Code:8

- Production Capacity:500sets,Month

Description

Basic Info.

Model NO. HG- Warranty 1 Year Color Blue Customized Customized Condition New Transport Package Carton Specification As per drawing Trademark X-ING Origin China HS Code 8 Production Capacity 500sets/MonthProduct Description

Abrasion resistance and impact resistance electric buffering rollerProduct application

The buffering roller used for large drop part in belt conveyor, setting a slowly rotating buffering roller in the coal

falling flow, equivalently divide the continuous coal falling flow into two sections, effectively reduce the final

speed of the coal flow reaches the feeding point of conveyor. In the conveying system, because of the process

set-up requirements, there are always have an unavoidable large drop transfer point, it can greatly improve the

operation condition to set a buffering roller.

Product structure

The buffering roller is composed of a enclosure, rotor and a transmission part, rotor is connecting with cycloidal

planetary gear speed reducer by cross slider coupling, both the enclosure and rotor adopt a welding structure,

compact structure, easy processing, impact resistance, abrasion resistance. Enclosure is closed, equipped with

inspection doors.

Product feature

On the transfer point in the conveyor system, the ambient air will be brought and sucked into coal pipe cause by

coal free falling flow, therefore coming into being positive pressure in the coal falling pipe then leak from coal

chute outlet and others gap, such air volume caused by coal flow is called induced air. The test indicated the

induced air is proportional to the height difference of the transfer point, after setting a buffering roller at the

transfer point, because the drop is reduced, which can reduce the induced air, sequentially reduce the dust

overflow at the coal falling pipe, in favour of environment dust concentration, improve working conditions. At the

same time, due to the reduction of the coal flow final speed, the impact of belt conveyor 's material receiving

point can be reduced, improve receiving condition and the service life of the belt conveyor and material

receiving buffering idler roller and other accessories can be prolonged.

Our workshop

Our sales team