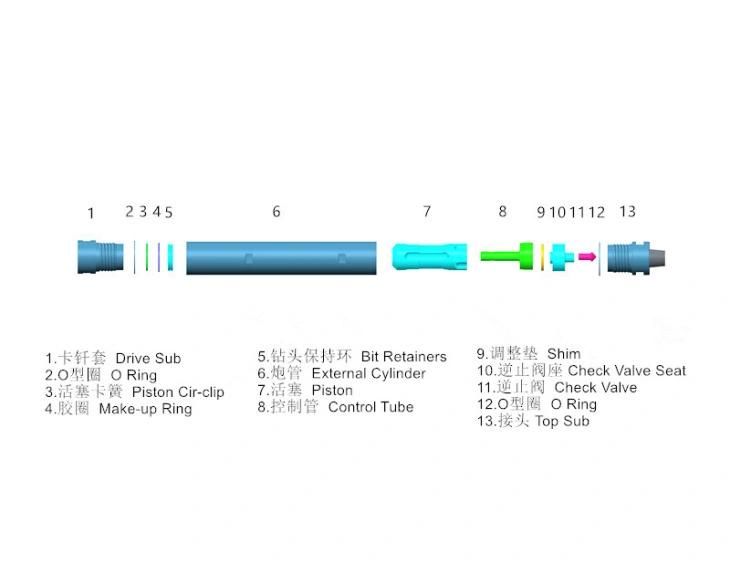

High Air Pressure Pneumatic DTH Hammer Mhsd40

WUHAN KINGDRILLING DIAMOND CO., LTD.- Certification:ISO 9001:2000, SGS

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Forging

- Material:Carbon Steel

- Transport Package:Wooden Case

Base Info

- Model NO.:MHSD40

- Trademark:MING

- Origin:Made in China

- HS Code:8431432000

- Production Capacity:20000PCS,Year

Description

24BAR/348PSI-2506CFM

480

Advantages:

1. Deliver maximum energy to drilling bit, fast drilling speed and low air consumption due to the special inner structure of DTH hammer designed according to advanced rock drilling theory.

2.Unique design to maximize productivity and longest service life of DTH hammer due to high quality raw materials and know-how heat treatment process.

3. Low problem rate and easy to maintenance due to simple, reliable inner structure of hammer.

4. Interchangeable with DTH drill bit, DTH drill pipe and easy assemble and disassemble.

How to order?

Shank Type + Top Sub Thread + (With/Without Valve, if this parameter is optional)

How to choose the suitable Pneumatic DTH hammer?

a. Hole Size:

It is better for you to choose the one which the outside diameter is nearest to the hole diameter. This will reduce the hole collapse, and the hole cleaning is easier.

b. Air Consumption:

You must consider about the consumption of compressed air when you use the Pneumatic DTH hammer. Generally speaking, with the raising of the size of hammer, peak performance requires higher compressed gas consumption and lower pressure. In order to make sure each hammer will be used in the proper consumption of compressed air and pressure, please refer to the attachment.

c. Drill rig Capacity:

The larger bit and hammer will need the drilling rig to provide greater torque and promoting force, but do not exceed the maximum load of the drill. As for the other questions about drill ability, please consult your sales representative.

FAQ:

1. How to order the products?

A: Please send the inquiry with detail item description or with Model number.

2. How to control quality?

A: We have our own experienced QC team,there will be strict inspection and testing for each order before shipping out.

3. Fast delivery time:

A: Usually it takes 25 days for production.only 3 or 5 days if we have stock of your request size.

4.What is the general delivery time?

15 working days for DTH bits.

20-25 working days for DTH hammer

3-5 working days for ex stock items.

5.Methods of Payment:

T/T (Telegraphic Transfer) or Western Union.

6. What is the materials?

Steel is TIMKEN, Alloy is from T6 from Element Six.

Product Application:

Transport:

Package and Delivery:

Packed by Carton or Wooden cases.

Delivery:

- Goods in stock can be delivered within 5 days.

- DTH Bits production time is about 15 days.

- DTH Hammer product time is about 30 days.

More products: