High Efficiency Grinding Mill Equipment

Hengtu Industry Co., LTD.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:132 Kw

- Rotationl Speed:1200-3000rpm

- Application:Mine

- Materials:Calcium Carbonate,Talc,Clay,Barite,Quartz

Base Info

- Condition:New

- Transport Package:Wooden Boxes and Loose Packing

- Specification:customized

- Trademark:HT

- Origin:China

- HS Code:8474201000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Condition New Transport Package Wooden Boxes and Loose Packing Specification customized Trademark HT Origin China HS Code 8474201000 Production Capacity 100 Sets/MonthProduct Description

Wet grinding millProduct introduction

Wet grinding mill is a large superfine grinding equipment developed by our company after improvements. It can crush materials into powder in 2000 to 8000 mesh or even finer powder by using scientific grinding medium ratio. Wet grinding mill works continously by feeding materials from the base through pump,frequency-conversion motor drives main shaft at stable speed to grind the ball and materials and generate high-energy movement among materials and medium ball,creating crash,shear and friction so as to meet best powder requirement. Water mill can operate independently or lingking several mills to flexibly meet our customers' various production demands. It enjoys a wide rang of applications,bringing good processing effects for nonmetallic minerals including calcium carbonate,barite,clay,gypsum and talc etc.

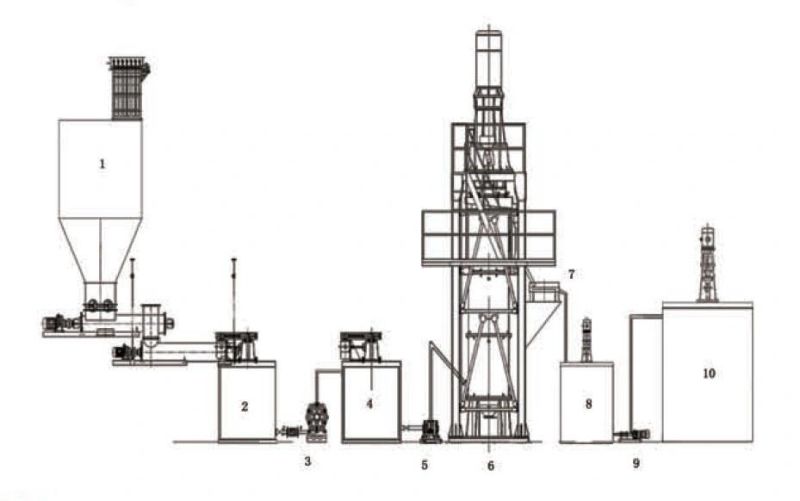

1. material bin 2. mixture bin 3.conveyor pump

4.buffer tank 5.feed pump 6. water mill

7.vibrating sifter 8.middle tank 9. discharge pump

10. finished product bin

Technical advantages:

a.Space-saving

b.Finished powder size is controllable

c.Easy to operate

d.Flexible and reliable

f.Simple installation

g.Low maintenance cost

Application.

It can be used to produce calcium carbonate,silicon power,magnesium hydroxide,aluminum hydroxide,clay,barium sulfate,red iron oxide,graphite,attapulgite,alumina,talc powder and mica etc.

| Model Parameter | LYSM-1500 | LYSM-3800 |

| Feeding size(mesh) | 200-400 | 200-400 |

| Ouput(t/h) | 1.8-3 | 2-6 |

| Power consumption (kw.h/t) | 30-124 | 30-134 |

| Motor power(kw) | 160 | 250 |

| Ball loss(kg/t) | 0.2-0.8 | 0.2-0.8 |

| L*W*H(mm) | 3000*3000*5500 | 3600*3600*8600 |

Service & support

With a team of experienced engineers with a strong sense of service ,we devoted to build up a complete customer services system with high efficiency to offer high value-added technical support and professional after sale services for customers.

1. Pre-sale

1)Equipment sizing assistance based on customer's demand.

2). Assistance in planning the layout of workshop according to the customer's site conditions.

3)Free design of the foundation drawing and process flow diagram.

4)Guidance on preparatory work.

2. During sale.

1).Strictly control of product production to ensure product quality.

2)Elimination of hidden dangers with strict factory inspectation and traceability system.

3)Providing logistics information.

4)Free guidance on the preparation of equipment foundation.

5)Free guidance for installation and commissioning.

6) Free professional technical training.

3. After-sale.

1)Guidance on various powder production process for customer.

2)Periodic follow-up on device usage.

3)Instructions on equipment maintenance.

4)Solution of relevant problems in the shortest time.

5)Timely and efficient replacement of spare parts.

6)Professional and fast equipment maintenance.