6 Inch 168mm Symmetric Casing System with Slide Block

Changsha Sollroc Engineering Equipments Co., Ltd.- Transport Package:Cartons + Ply-Wooden Cases for Exporting

- Trademark:Sollroc

- Origin:Changsha

Base Info

- Model NO.:168mm Symmetric Casing System With Slide Block

- HS Code:84314320

- Production Capacity:5000pieces,Month

Description

Product Name:

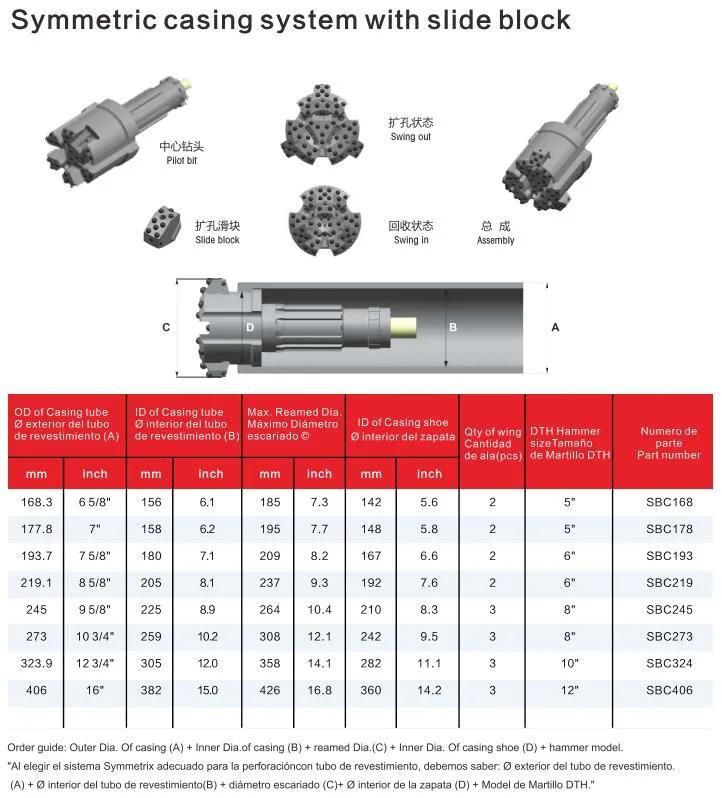

Product specifications: Concentric casing system with block

Products Photos:

Operating principle:

1. When drilling starts, the reamer swings out and reams the pilot-hole wide enough for the casing tube to slide down behind the drill bit assembly.

2. When the required depth is reached, rotation is reversed carefully, whereupon the reamer swings in, allowing the drill bit assembly to be pulled up through the casing.

3. Casing tubes that are to be left in the drill hole should be sealed at the bottom of the hoe by means of cement grout or some other sealing agent.

4. Drilling continues to the desired depth in the bedrock using a conventional drilling tools.

Our Products Advantage:

[1] Appearance: Since the heating process has a complete and stable process, the appearance of the product can be kept consistent, and the appearance will not be angular and will not hurt the hand.[2]Product intrinsic: The service life has completely exceeded atlas and sandvic.

[3] QC:4 times inspection and 1 test.

[4] First inspection: quality management will conduct all inspections at the beginning of product production

[5]Sampling inspection: the product will be sampled during processing

[6] Quality inspection: Full inspection is performed every time the next process is delivered

[7] Final inspection: the product is sent to the inspection room for final inspection.

FAQ:

Why choose us?

1) We have more than 20 years of researching,developing, manufacturing and exporting

high quality rock drilling equipments and penumatic tools to the global market.

2)High quality compatible with Sandvik, Atlas Copco, Ingersoll Rand etc...

3)Reasonable price

4)Excellent service.

5.Which port do you shipping from?

We usually ship container from Shanghai port.Guangzhou,ShenZhen port is available too.

6.Can you accept OEM & ODM ?

Yes, both of them are acceptable.

7.What is your minimum order quantity?

Our MOQ are 1pc or 1 complete set, the price may rely on the order quantity.

8.What is your payment term?

We can accept L/C, D/A, D/P, T/T, Western Union, MoneyGram.

9.How about the delivery time?

It depends,generally it takes about 15-25.If have stocks,Usually only 5-10 days if in stock.

Quality warranty:

Our hammers are made of high quality steel and all spares are inspected strictly before shipping. We have quickly responses for your complaint and suggestion.

Package:

Using ply-wooden cases and pallet for exporting to protect products and avoid the damagement during transportation. Also we can customize package according to your special requests.

Transportation:

By air, By Express or By sea according to your requests