Waste Steel Asr Fluff Recovery Recycling Line Plastic Machine Aluminum Alloy Glass ...

Fushun Ejet Magnetic Equipment Co., Ltd.- Type:Magnetic Separator

- Voltage:Standard

- Weight:2000kg , as Required

- Material:Depend on Model

- Material Feature:Depend on Model

- Certification:ISO9001:2000, CE, SGS

Base Info

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Yellow

- Customized:Customized

- Condition:New

- Recovery Rate:98.5 - 99.5 %

- Processing Capacity:0-12ton,Hour

- Dimension(L*W*H):3670X2000X1285mm

- Motor:Nord

- Belt:Forbo Siegling

- Bearing:NSK

- Reducer:Schneider

- Power:5.5+3.0+0.55*2(Kw)

- Eddy Current Separator Belt:Forbo Siegling

- Size Nonferrous Metal Separation:Custom Size

- Application:Nonferrous Metal Separation

- Features:Non-Ferrous Metal Recovery

- Product Keywords:Nonferrous Separators

- Installation:Engineer Guidance

- Feeding Size:≥3mm

- Transport Package:Export Packing

- Specification:magnetic separator recycling machine

- Trademark:JSYY

- Origin:Fushun, Liaoning, China

- HS Code:85051190

- Production Capacity:50sets,Month

Description

Basic Info.

Energy Saving Energy Saving Warranty 1 Year Color Yellow Customized Customized Condition New Recovery Rate 98.5 - 99.5 % Processing Capacity 0-12ton/Hour Dimension(L*W*H) 3670X2000X1285mm Motor Nord Belt Forbo Siegling Bearing NSK Reducer Schneider Power 5.5+3.0+0.55*2(Kw) Eddy Current Separator Belt Forbo Siegling Size Nonferrous Metal Separation Custom Size Application Nonferrous Metal Separation Features Non-Ferrous Metal Recovery Product Keywords Nonferrous Separators Installation Engineer Guidance Feeding Size ≥3mm Transport Package Export Packing Specification magnetic separator recycling machine Trademark JSYY Origin Fushun, Liaoning, China HS Code 85051190 Production Capacity 50sets/MonthProduct Description

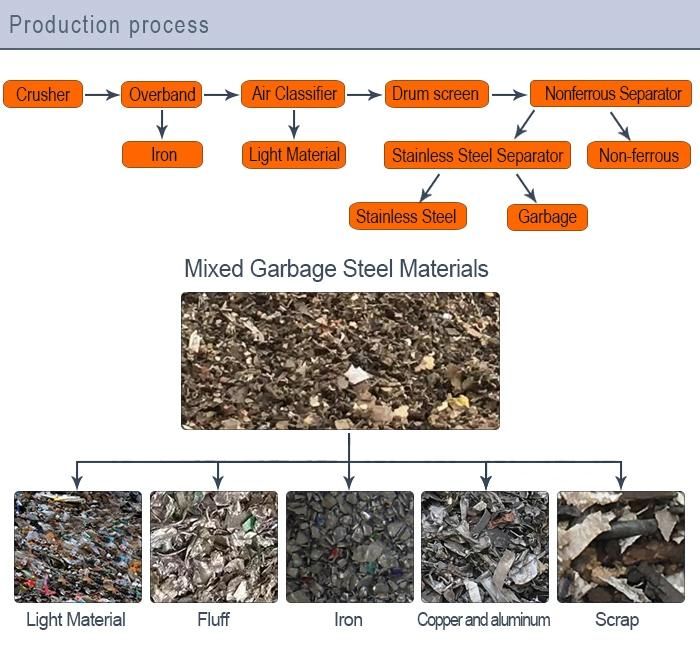

Waste steel recycling plastic machine

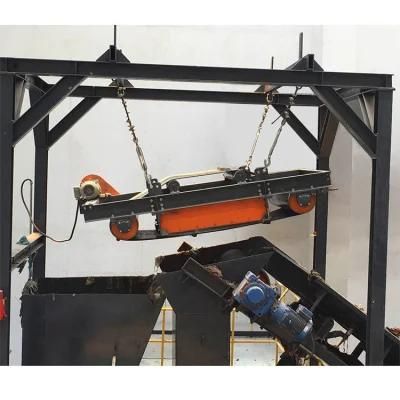

The Magnetic Separating System for Steel Scrap is used for waste steel recycling.

This system could deal with waste tailing pollution of steel industry, separate non-ferrous metal, stainless steel, robber, plastic etc from the waste tailing.

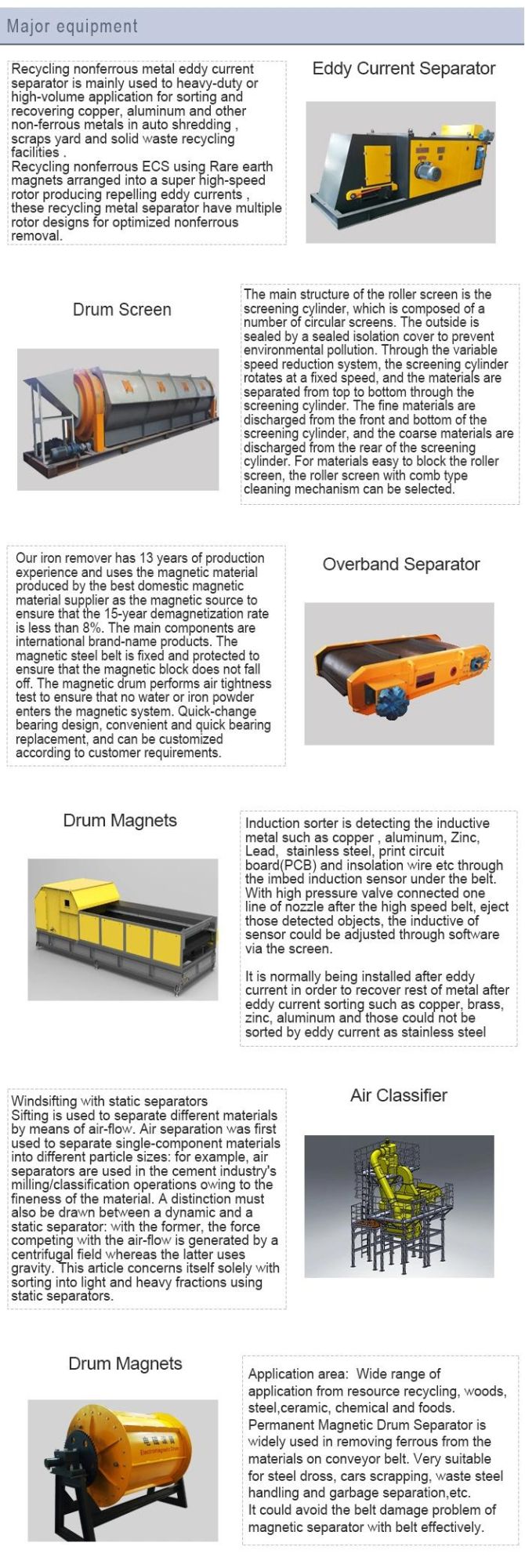

Fushun Ejet Machinery Co., Ltd. is located in the national advanced energy equipment high tech industrialization base Fushun Economic Development Zone is an enterprise specializing in the R & D and manufacturing of magnetic separation equipment and resource recovery equipment. Its products are widely used in solid waste treatment, metallurgical mines, power plants, coal mines and other industries. The main products of the company are the complete set of special solid waste separation equipment such as scrap crushing tailings automatic separation line, papermaking waste separation line, waste plastics separation line and eddy current separator, magnetic separation machine Machine, stainless steel separator and other magnetic separation equipement.

Try to Read This -------Our Service

1. Maintenance free of charge for 12 months .

2. We will provide the consumable parts at an agency price.

3. 24 hours online service, free technical support.

4. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

5. We have manual instruction and Videos for software Installation, operation and machine's using and maintenance; We will send professional technician to customers' factory, provide them two-weeks training, including working principle of machine, Auto CAD drawing, common problems and solution, etc.

1. What is the MOQ of your machine?

A: Our MOQ is 1 set

2. How long is the machine warranty period?

A: the product warranty period is 12 months

3.What kind of metal is eddy current applied to?

A:Eddy Current Separator suitable for aluminum, copper, brass.etc non-ferrous scraps separation from non - metal materials of size >3mm.

4.Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition , size ,handling capacity and expected separation result .

5.What are the pros and cons between a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much suitable for complicated material situation , The eccentric rotor design reduces long-term wear due to heated ferrous build up ,can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence , the concentric type have a little bit better separation effect,but must make sure no ferrous exist.

Any questions in metal solution , please feel free contact with us .