Fine Gold Recovery Equipment Gold Shaking Table for Gold Washing Plant

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd.- Type:Gravity Separator

- Weight:1T

- Certification:ISO9001:2008, ISO9001:2000

- Energy Saving:Energy Saving

- Warranty:1 Year

- Condition:New

Base Info

- Application:Mineral Gravity Separation

- Slurry Density:30-50%

- Feeding Size:0.074-2mm

- After-Service:Provide

- Installation Guide:Provide

- HS:8474100000

- Trademark:ZONEDING

- Origin:China

- HS Code:8474100000

- Production Capacity:0.5-2t,H

Description

Eccentric link structure

Working pinciple:

The vertical and reciprocating motion of the deck is driven by the crank-connecting actuator. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod makes a downward movement, the toggle plate pushes back shaft and reciprocating lever backward. meanwhile, through the tension of spring, it drives the deck to move backward, because the deck is connected with the reciprocating lever by linkage seat. When the rod moves upward, through the force from spring tension, the deck makes a forward movement. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. With the rod moving down, minerals on tilting deck installed by rifle spokes go into the feed box. meantime, water stored in the water tank impacts the minerals laterally. So by the means of shaking and washing, minerals of different sizes and densities flow from discharge outlets, which separate concentrates and tailings clearly and efficiently. Since the mining table concentrators have been upgrading in line with advanced technologies, their production and accuracy have improved significantly.

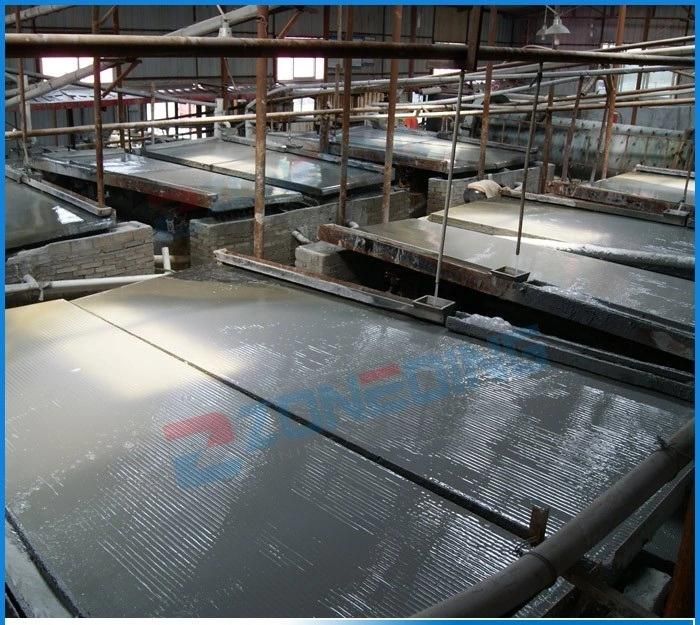

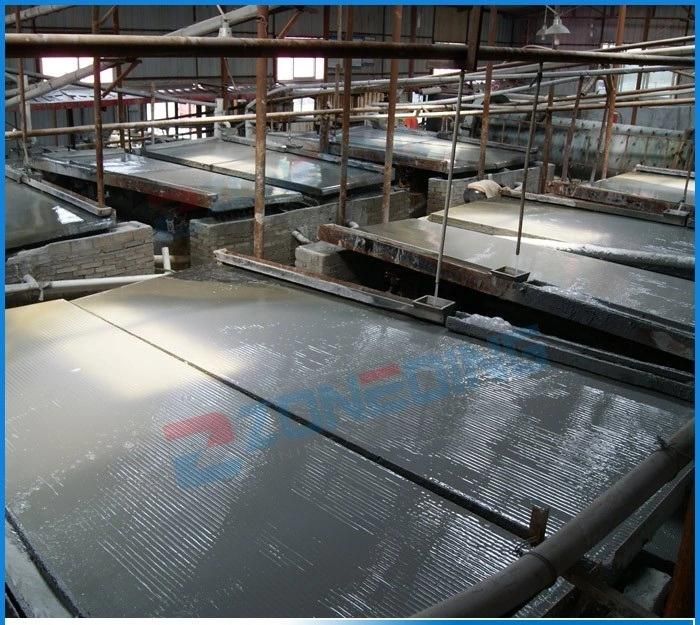

Working site:

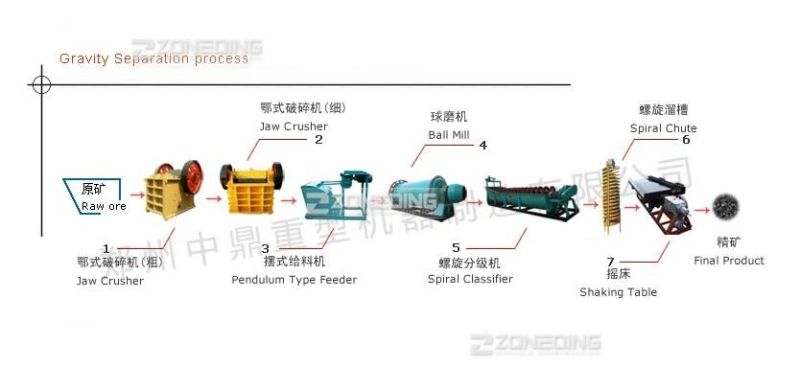

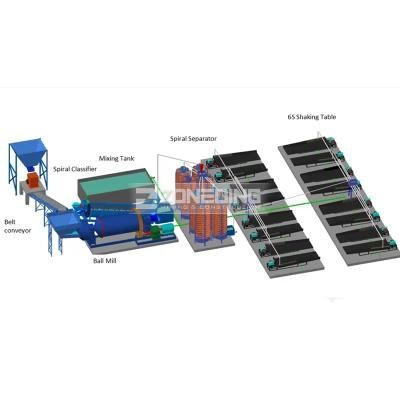

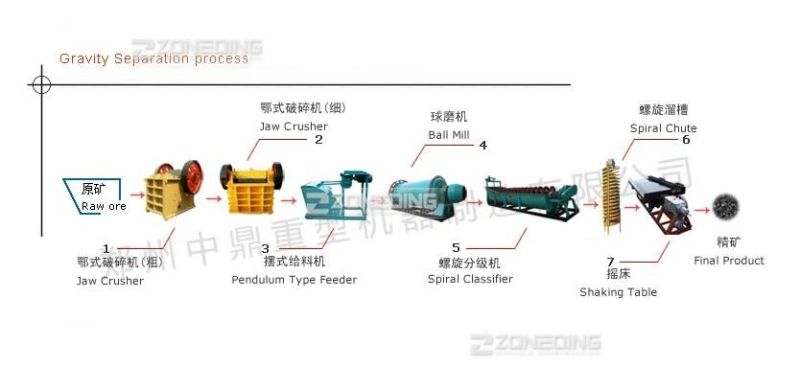

If you need a complete processing line, please contact us for more data!

Working pinciple:

The vertical and reciprocating motion of the deck is driven by the crank-connecting actuator. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod makes a downward movement, the toggle plate pushes back shaft and reciprocating lever backward. meanwhile, through the tension of spring, it drives the deck to move backward, because the deck is connected with the reciprocating lever by linkage seat. When the rod moves upward, through the force from spring tension, the deck makes a forward movement. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. With the rod moving down, minerals on tilting deck installed by rifle spokes go into the feed box. meantime, water stored in the water tank impacts the minerals laterally. So by the means of shaking and washing, minerals of different sizes and densities flow from discharge outlets, which separate concentrates and tailings clearly and efficiently. Since the mining table concentrators have been upgrading in line with advanced technologies, their production and accuracy have improved significantly.

Working site:

If you need a complete processing line, please contact us for more data!