High Efficiency Tailings Thickner / Concentrator

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Normal Thickener

- Motor Type:AC Motor

- Motor Power:Depend on The Model

- Diameter:Depend on The Model

- Application:Mine

- Condition:New

Base Info

- Model NO.:nzs

- Product Name:High Efficiency Tailings Thickner , Concentrator

- Keyword:Concentrator

- Color:Request

- Installation:Engineers Guide

- Market:Europe

- Price:Negotible

- Motor:Chinese Famous Brand

- MOQ:1 Set

- Transport Package:Wooden Case, Standard Container

- Specification:NZS

- Trademark:hengchang

- Origin:China

- HS Code:8421191000

- Production Capacity:10 Set,Day

Description

Basic Info.

Model NO. nzs Product Name High Efficiency Tailings Thickner / Concentrator Keyword Concentrator Color Request Installation Engineers Guide Market Europe Price Negotible Motor Chinese Famous Brand MOQ 1 Set Transport Package Wooden Case, Standard Container Specification NZS Trademark hengchang Origin China HS Code 8421191000 Production Capacity 10 Set/DayProduct Description

Product Application Of High Efficiency tailings thickner / concentrator

Vacuum filter is the solid-liquid separation equipment driven by vacuum negative pressure with the advantages of high filtration efficiency, production capacity, washing effect, low cake moisture, flexible operation, low maintenance cost and so on. Especially for the magnetic minerals dehydration, this machine is 3 times bigger than other filter capacity. Widely used in metallurgy, mining, chemical, paper, food, pharmaceutical, environmental protection and other areas.

Parameters Of High Efficiency tailings thickner / concentrator :

| model | GW-3 | GW-5 | GW-8 | GW-10 | GW-12 | GW-20 | GW-30 | GW-40 | GW-50 |

| Filter area (m2) | 3 | 5 | 8 | 10 | 12 | 20 | 30 | 40 | |

| Cylinder size (mm) | φ1068× 1060 | φ1600× 1060 | φ2000× 1500 | φ2000× 1750 | φ2000× 2000 | φ2500× 2650 | φ3350× 3000 | φ3350× 4000 | φ3350× 5000 |

| cylinder speed (r/min) | 0.156- 1.56 | 0.156- 1.56 | 0.1-0.6 | 0.1- 0.6 | 0.1- 0.6 | 0.14- 0.54 | 0.12- 0.56 | 0.12- 0.56 | 0.12- 0.56 |

| Vacuum pressure(KPa) | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Swept volume (m3/min.m2) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Blast pressure (Kpa) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| blast volume (m3/min.m2) | 0.2- 0.4 | 0.2- 0.4 | 0.2- 0.4 | 0.2- 0.4 | 0.2- 0.4 | 0.2- 0.4 | 0.2 -0.4 | 0.2- 0.4 | 0.2- 0.4 |

| capacity (t/h) | 0.8-1.5 | 1.6-2.4 | 2.8-3.6 | 3-4 | 3-5 | 3-8 | 4.5-12 | 6-16 | 7.5-20 |

| cylinder motor(kw) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 5.5 |

| Stirring motor (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 |

| weight (kg) | 2635 | 2850 | 5455 | 6317 | 6365 | 10600 | 17200 | 19500 | 21500 |

Main Features Of High Efficiency tailings thickner / concentrator

High vacuum degree, low concentration of filtrate and high filter efficiency Small occupied area, low power consumption. Can be recycled to use., reduce the emission Highly automatic, reduce labor cost Easy installation and maintenance Reliable structure and long lifespan

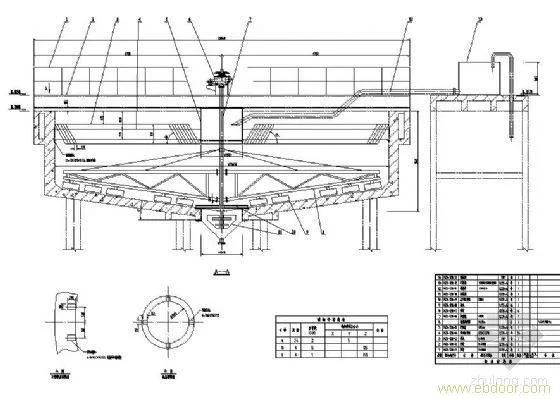

Working Principle Of High Efficiency tailings thickner / concentrator

Concentrator mainly consists by two parts, the circular pool and rake scraper. Solid particles suspend in the slurry are settled due to gravity, upper part is clarified water, thus the solid and liquid can be separated. Slurry that deposited on the bottom of the pool is continuously scraped by rake scraper to the discharge port at bottom centered and discharged, and the clarified water overflows along the upper edge of the pool.

Detailed Images Of High Efficiency tailings thickner / concentrator

Delivery Of High Efficiency tailings thickner / concentrator

Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant was built in 1992, is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry