Grinding Ball Mill Mineral Powder Ball Mill for Gold Mining

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:18.5KW

- Rotationl Speed:38rpm

- Application:Gring Ores Into Fine Powder

- Materials:Gold

Base Info

- Model NO.:1200*4500, 2830*4500

- Condition:New

- Model Number:Wet Grinding Ball Mill

- Capacity(T/H:1-50tph

- Certificate:ISO9001-2008

- Input Size:25mm and Down

- Output Size:0-250mesh(Adjustable)

- Working Ways:Dry and Wet Type Ball Mill

- Installation:We Dispatch Engineer

- Spare Parts:Supply for Whole Life

- Warranty:1 Year Apart From Wearing Parts

- Name:China Professional Ball Mill Manufacturer with COM

- Transport Package:Standard Export Container,Small Parts by Wooden Bo

- Specification:International Standard

- Trademark:HengXing

- Origin:China

- HS Code:84742020

- Production Capacity:5-80t,H

Description

Basic Info.

Model NO. 1200*4500, 2830*4500 Condition New Model Number Wet Grinding Ball Mill Capacity(T/H 1-50tph Certificate ISO9001-2008 Input Size 25mm and Down Output Size 0-250mesh(Adjustable) Working Ways Dry and Wet Type Ball Mill Installation We Dispatch Engineer Spare Parts Supply for Whole Life Warranty 1 Year Apart From Wearing Parts Name China Professional Ball Mill Manufacturer with COM Transport Package Standard Export Container,Small Parts by Wooden Bo Specification International Standard Trademark HengXing Origin China HS Code 84742020 Production Capacity 5-80t/HProduct Description

Grinding Ball Mill Mineral Powder Ball Mill For Gold MiningBall Mill Application: Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: The dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine.

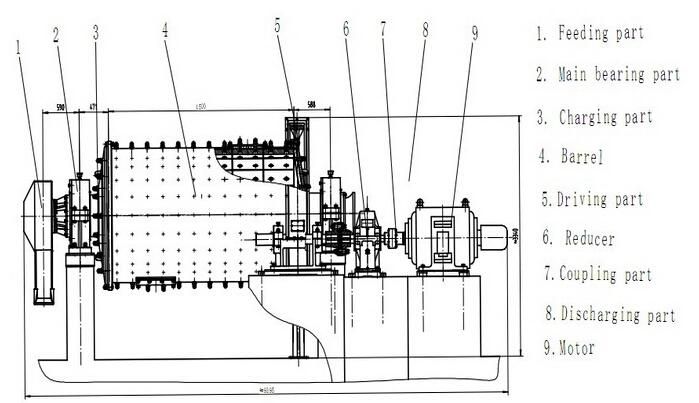

Ball mill strucuture:

Ball mill is made up of feedisng part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, motor, electrical control) and so on.

The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This machine run steadily and works reliably.

How Ball Mill Works

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Ball Mill Features:

1. Large application range, simple structure and convenient maintenance;

2. Large capacity and continuous work are very obvious;

3. Barrel lining and grinding media can apply various abrasive materials;

4. Installation and adjustment are very convenient and easy to be operated.

Ball Mill Technical Parameters:

| Model | Shaft rotation speed (r/min) | Ball load (t) | Feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Power (KW) | Weight (T) |

| Φ 900 × 1800 | 38 | 1.5 | ≤ 20 | 0.075 -0.89 | 0.65-2 | 18.5 | 3.6 |

| Φ 900 × 2100 | 38 | 1.3-1.4 | ≤ 15 | 0.075 -0.83 | 0.7-3.5 | 18.5 | 3.9 |

| Φ 900 × 3000 | 38 | 2.7 | ≤ 20 | 0.075 -0.89 | 1.1-3.5 | 22 | 4.5 |

| Φ 1200 × 2400 | 32 | 3.8 | ≤ 25 | 0.0745-0.6 | 1.5-4.8 | 30 | 11.5 |

| Φ 1200 × 2800 | 32 | 3.3-3.5 | ≤ 25 | 0.0745-0.6 | 2-6 | 30 | 13 |

| Φ 1200 × 4500 | 32 | 7 | ≤ 25 | 0.074 -0.4 | 1.6-5.8 | 45 | 13.8 |

| Φ 1500 × 3000 | 27 | 8 | ≤ 25 | 0.074 -0.4 | 2-5 | 75 | 17 |

| Φ 1500 × 3500 | 27 | 6.75 -6.4 | ≤ 25 | 0.075 -0.4 | 3-7 | 75 | 17.5 |

| Φ 1500 × 4500 | 27 | 14 | ≤ 25 | 0.074 -0.4 | 3.5-12 | 110 | 21 |

| Φ 1500 × 5700 | 27 | 15 | ≤ 25 | 0.074 -0.4 | 3.5-8 | 115 | 24.7 |

| Φ 1830 × 3000 | 24 | 18 | ≤ 25 | 0.074 -0.4 | 4-10 | 130 | 28 |

| Φ 1800 × 3600 | 24 | 10.6-11.35 | ≤ 25 | 0.075 -0.4 | 5-22 | 130 | 33.5 |

| Φ 1830 × 7000 | 24 | 25 | ≤ 25 | 0.074 -0.4 | 7.5-17 | 210 | 36 |

| Φ 2100 × 3600 | 22 | 14-15.2 | ≤ 25 | 0.075 -0.4 | 15-36 | 370 | 46.8 |

| Φ 2200 × 5500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 10-20 | 210 | 48.5 |

| Φ 2200 × 6500 | 21 | 31 | ≤ 25 | 0.074 -0.4 | 14-26 | 380 | 52.8 |

| Φ 2200 × 7500 | 21 | 33 | ≤ 25 | 0.074 -0.4 | 16-29 | 380 | 56 |

| Φ 2400 × 3000 | 20.6 | 15.5 -16.6 | ≤ 25 | 0.075 -0.4 | 22-24 | 245 | 59 |

| Φ 2400 × 4500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 8.5-60 | 380 | 65 |

| Φ 2700 × 3600 | 20.6 | 39 | ≤ 25 | 0.074 -0.4 | 12-70 | 400 | 91.3 |

| Φ 2700 × 4000 | 20.7 | 40 | ≤ 25 | 0.074 -0.4 | 12-80 | 400 | 94 |

| Φ 2700 × 4500 | 20.7 | 48 | ≤ 25 | 0.074 -0.4 | 12-90 | 430 | 102 |

| Φ 3200 × 4500 | 18 | 65 | ≤ 25 | 0.075 -0.4 | According to the technics | 800 | 137 |

Ball Mill Delivery From Our Factory:

About factory :

About Installation and Commissioning

we are able to guide the overall installation of whole setball mill production line, including stone crushing production line and ball mill production line,rotary dryer production line, etc., which will allow you to start the normal operation of equipment immediately and successfully.

How do you do QA?

A:We have special team do strict QA,this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

Contact us :Ms Sara Pang