Rotary Kiln Wheel &Rotary Kiln Supporting Roller

Luoyang Zhongtai Industries Co., Ltd.- After-sales Service:Twenty Four Hour Online

- Warranty:a Year

- Kiln Tyre:Rotary Kiln Support Roller & Rotary Kiln Tyre

- Weight:From 3 Tons to 200 Tons Per Piece

- Standards:ASTM,BS,NF,DIN,JIS and So on;

- Material:Zg20simn,Zg50mn,Zg35s

Base Info

- Model NO.:Rotary Kiln Wheel &Rotary Kiln Supporting Roller

- Certificate:ISO 9001:2008

- Range of Application:for Rotary Kiln&Rotary Dryer

- Rotary Kiln Tyre Material:Alloy Steel Cabon Steel etc. Casting or Forging

- Max.Od in Our Business Line:Within 10,000mm

- Kiln Tyre Diameter:2m-9m

- Kiln Tyre Application:Used for Industrial Purpose, and Especially Used O

- Transport Package:Rotary Kiln Support Roller and Tyre

- Specification:Rotary kiln support roller

- Trademark:ZTIC

- Origin:Luoyang, Henan

- HS Code:8417100000

- Production Capacity:2000PCS,Year

Description

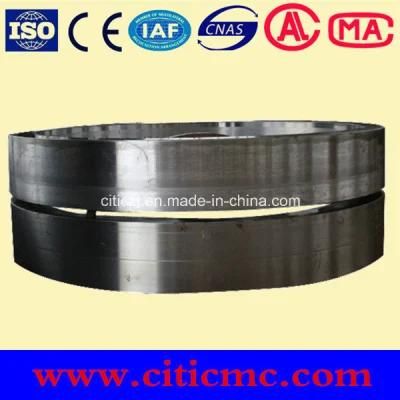

Rotary kiln is widely used in processing industries, such as cement, ore processing and chemical. The kiln is a cylindrical shell slightly inclined to the horizontal position and supported by tyres. A Girth gear and pinion assembly rotates the entire system. Material enters the kiln at the upper end and moves to words the lower end. With continuous mixing and a supply of hot air the desired chemical reaction is completed at the lower end and thus the processing is continuous. The kiln shell has a fire brick lining to protect the outer steel shell from the high temperatures existing inside. The tyre is a cylindrical ring supporting to the kiln shell. Tyre is cylindrical cast or forged sin gle ring. Following picture gives general arrangement of tyre and rollers.

Rotary Kiln Support Roller

Kiln Support Rollers are backed by latest technology and provide desired support to cables and other related products. These support rollers are driven to rotate using friction between roller surface and web. The small friction torque of the roller bearings also allow higher speed operations and helps in avoiding possibilities of slippage due to presence of large air film between roller surface and web.

FAQ

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.