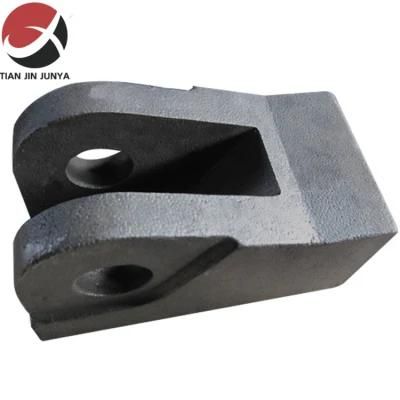

Crusher Hammer Head in Mining Machinery Wear-Resisting Parts

Tianjin Junya Precision Machinery Co., Ltd.- After-sales Service:Order Status Weekly Updates

- Warranty:1 Year

- Certification:CE, ISO 9001:2000

- Standard:AISI, ASME, BS, ANSI, JIS, GB, ASTM, DIN

- Surface Treatment:Customized

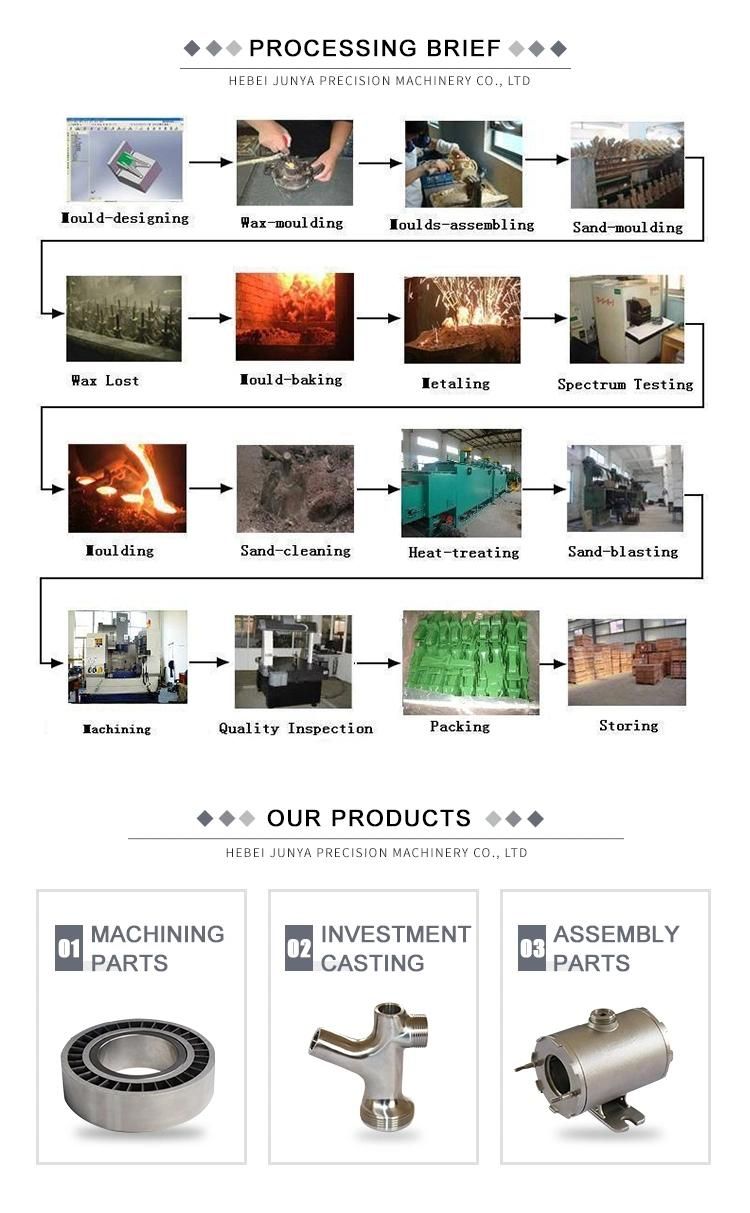

- Manufacturing Process:Casting

Base Info

- Model NO.:OEM

- Material:High Manganese Steel

- Condition:New

- Machine Type:Crusher

- Use:Coal Mining

- Weight:as Drawing

- Quality:100% Suit Original

- Diameter:Customized

- Drawing Format:All Format

- Business Type:Manufacturer

- Delivery Time:30-45 Days

- Place of Origin:Tianjin China (Mainland)

- Machining Process:CNC Finishing Process

- After Sale Service:Order Status Weekly Updates

- Quality Control:Ipqc, Fqc

- Freight Method:Air,Sea

- Sample Leading Time:10-40 Days

- Transport Package:Provide as Required

- Specification:Various type of drawing,require

- Trademark:Junya

- Origin:China

- HS Code:8474900000

- Production Capacity:1000 Ton,Year

Description

valve parts, architectural parts and furniture parts so on

• Textile equipment

Quality Control

1) Checking the details before the production line operated

2) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

3) Checking the goods after they are finished---- Final quality control(FQC)

4) Checking the goods after they are finished-----Outgoing quality control(OQC)

*Our wax casting product processed by 79 steps with high standard and 100% inspection. Along with the power of our advanced machine, quality is something you do not need to worry about.

Hebei Junya Precision Machinery Co. Ltd is a high-tech enterprise combine designing, tooling developing, casting, machining, surface treatment, inspection, sales and service all together. Founded in 2017, located in Huanghua, Hebei. Junya now covers an area of more than 5000 square meters.

With a massive research & development environment, Junya utilized market-leading technology and introduced various of advanced equipment to ensure the stringent quality in production.

Under a powerful management team, the company has growing to the group with more than 100 employees. Product offerings range from Stainless Steel Pipe Fitting, Quick Joint, Ball Valve, Check Valve, to Marine Hardware and Auto Parts. The material are 304, 304L, 316, 316L, SF8M, WCB, 1.4408, etc.

-Quality- -Creativity- -Consistency-

These words are Junya slogan, and also philosophy that drives the company to offer the superior service you are looking for.

1) Design assistance and full engineering support .

2) Professional at OEM & ODM parts .

3) Excellent after sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

FAQ:

Q1: How long is your delivery time?

A:Delivery time is depends on the total quantity of order. Normally, sample can be delivered within 15 days.

Q2: Do you provide samples? Is it free or extra?

A:Yes, we could offer sample for free, and we can pay for the model as well, but the clients has to pay for the shipping cost.

Q3: What is the MOQ of your products?

A:It depends on the category of order.

Q4: Where is your factory?

A:Our factory located in Hebei province, close to Tianjin seaport.

Q5:What does your company need to submit a quotation?

A:Drawing or Sample, together with relevant information, such as Quantity, Weight, Material.

Q6:What we do not have a drawing?

A:We can duplicate your sample and make drawing for your confirmation.