Small Grinding Ball Mill Machine with Diesel Engine

Zhengzhou Zhongjia Heavy Industry Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:15KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Condition:New

Base Info

- Model NO.:MQG

- Warranty:15 Month

- After-sales Service:15 Month Warranty

- Transport Package:Standard Export Packing

- Specification:Customized

- Trademark:zhongjia

- Origin:China

- HS Code:8474202000

- Production Capacity:10PCS,Month

Description

Basic Info.

Model NO. MQG Warranty 15 Month After-sales Service 15 Month Warranty Transport Package Standard Export Packing Specification Customized Trademark zhongjia Origin China HS Code 8474202000 Production Capacity 10PCS/MonthProduct Description

Ball mill, grinding ball mill machine, ceramic ball mill, rubber tire driven ball mill, rod mill, cement ball mill

Raw Material Ball Mill also named as grinding ball mill, raw material mill, material grinding mill, and clinker mill, is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and glass ceramics, and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics and the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mills, grate type and overflow type due to different ways of discharging material.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Power (kw) | Effective Volume (m3) | Max. Ball Load (t) | Weight (t) |

| MQY0918 | 900 | 1800 | 22 | 0.9 | 1.66 | 6.1 |

| MQY1212 | 1200 | 1200 | 18.5 | 1.14 | 2.4 | 11.5 |

| MQY1224 | 1200 | 2400 | 55 | 2.28 | 3.8 | 12.3 |

| MQY1515 | 1500 | 1500 | 60 | 2.2 | 6.4 | 15.4 |

| MQY1530 | 1500 | 3000 | 95 | 5 | 10 | 18.7 |

| MQY2122 | 2100 | 2200 | 155 | 6.6 | 14 | 46.8 |

| MQY2130 | 2100 | 3000 | 210 | 9 | 20 | 47.2 |

| MQY2136 | 2100 | 3600 | 210 | 10.8 | 22 | 52 |

| MQY2145 | 2100 | 4500 | 310 | 13.5 | 23.8 | 58 |

| MQY2430 | 2400 | 3000 | 280 | 12.1 | 23 | 69 |

| MQY2721 | 2700 | 2100 | 280 | 10.7 | 24 | 64 |

| MQY2736 | 2700 | 3600 | 400 | 17.8 | 32 | 97 |

| MQY2740 | 2700 | 4000 | 400 | 20.4 | 40 | 79 |

| MQY3231 | 3200 | 3100 | 630 | 21.4 | 45 | 108 |

| MQY3245 | 3200 | 4500 | 630 | 32.8 | 65 | 130 |

| MQY3254 | 3200 | 5400 | 1000 | 37.2 | 73 | 121 |

| MQY3645 | 3600 | 4500 | 1000 | 41.8 | 76 | 135 |

| MQY3650 | 3600 | 5000 | 1250 | 46.4 | 86 | 145 |

| MQY3660 | 3600 | 6000 | 1250 | 55.7 | 102 | 154 |

| MQY3690 | 3600 | 9000 | 1800 | 83 | 163 | 212 |

| MQY3867 | 3800 | 6700 | 1600 | 70 | 130 | 186 |

| MQY4067 | 4000 | 6700 | 1800 | 78 | 138 | 207 |

| MQY4561 | 4500 | 6100 | 2200 | 93 | 151 | 238 |

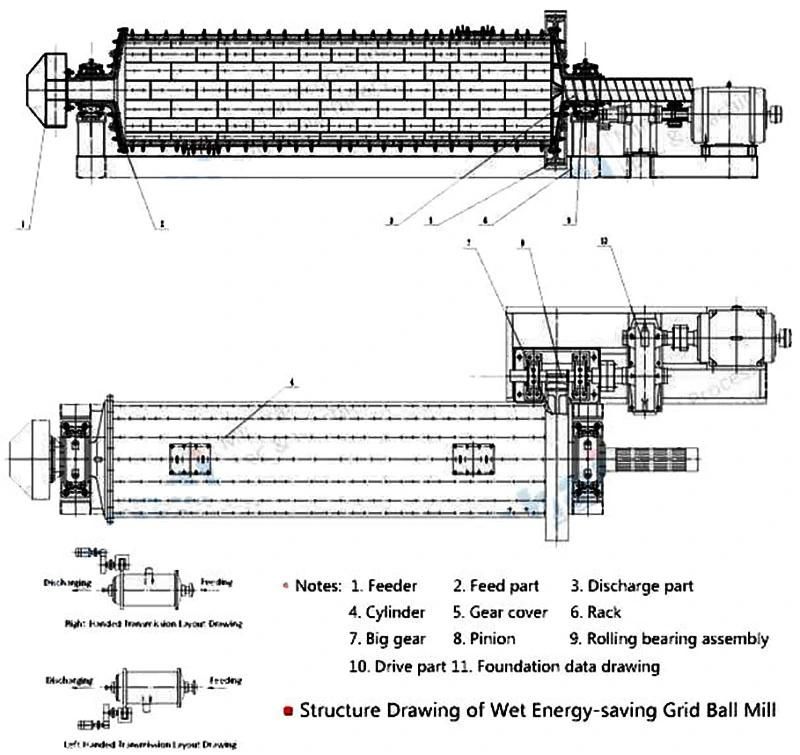

The ball mill is a horizontal rotating device transmitted by the outer gear

The materials are transferred to the grinding chamber through the quill shaft uniformly There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by the barrel rotation brings the steel balls to a certain height and impacts and grinds the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.