Small Stone Crushing Mining Small Portable Rock Crusher

SHANMAN (LINYI) MACHINERY CO., LTD.- Type:Composite Crusher

- Motor Type:AC Motor

- Motor Power:55HP

- Application:Construction

- Materials:Granite, Sand Stone, River Stone

- Outlet Size:0-60mm

Base Info

- Model NO.:GM4010

- Inlet Size:400×600mm

- Condition:New

- Max Feeding Size:340mm

- Capacity:40-60tph

- Weight:36.5t

- Size:16500X3500X3800mm

- Warraty:1 Year

- Color:as Your Request

- MOQ:1 Set

- Power Supply:Genorator

- OEM:Yes

- Factory Visit:Warmly Welcome

- Transport Package:Plywood Box, Container

- Specification:PE400x600, PF1010

- Trademark:shanman

- Origin:China

- HS Code:84742090

- Production Capacity:50000,Year

Description

Basic Info.

Model NO. GM4010 Inlet Size 400×600mm Condition New Max Feeding Size 340mm Capacity 40-60tph Weight 36.5t Size 16500X3500X3800mm Warraty 1 Year Color as Your Request MOQ 1 Set Power Supply Genorator OEM Yes Factory Visit Warmly Welcome Transport Package Plywood Box, Container Specification PE400x600, PF1010 Trademark shanman Origin China HS Code 84742090 Production Capacity 50000/YearProduct Description

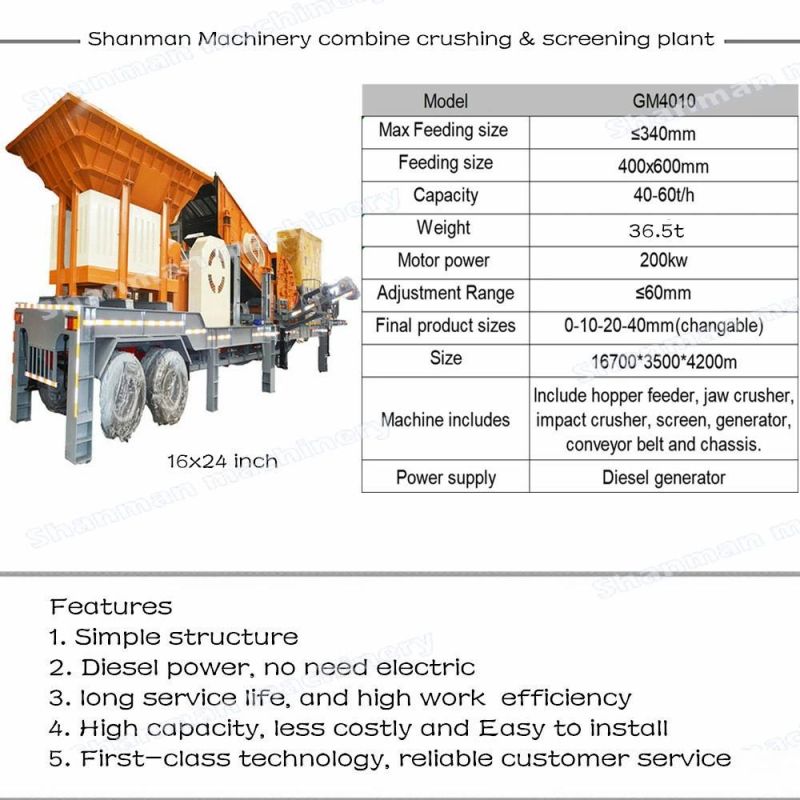

Small Stone Crushing Mining Small Portable Rock Crusher1. GM4010 combine crushing & screening plant details

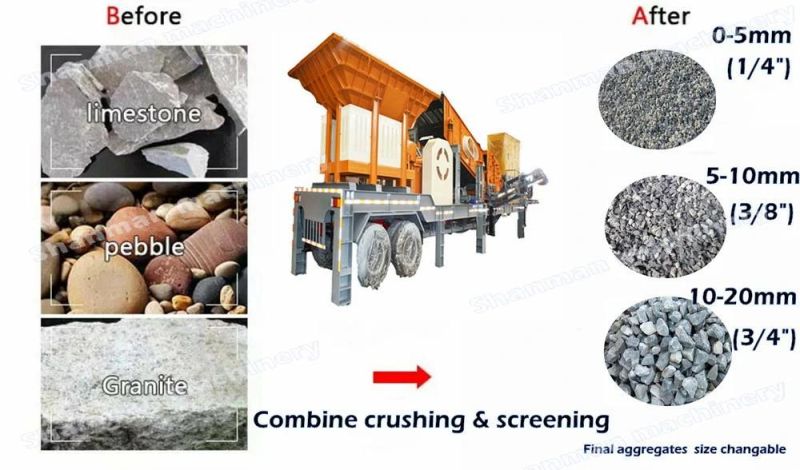

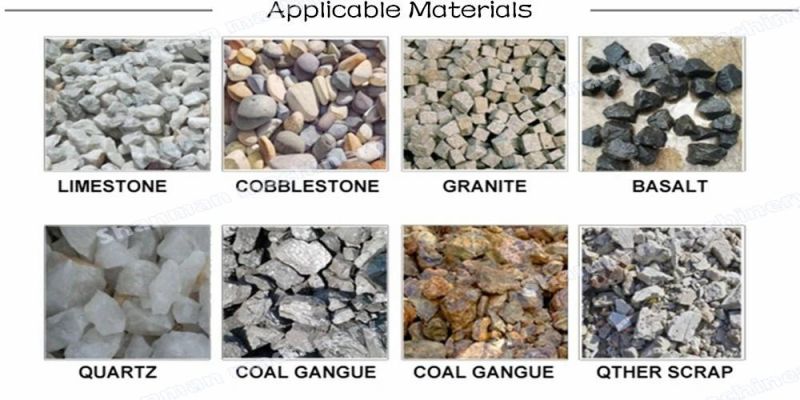

Shanman Model GM4010 combine stone crushing and screening mobile plant feeding size is 340 mm, output size is 0-60 mm, the final aggregate size is three type, such as 0-10-20-40mm, capacity is 40-60t/h. It's is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartz, alloys, etc,is a Single Toggle Roller Bearing machine.

2. GM4010 combine crushing & screening plant pictures show

This plant include: hopper feeder, jaw crusher, impact crusher, vibrating screen, conveyor belts, generator, mobile chassis. It is can work directly, no need any other equipment, no need electric.

3. Introduction

Mobile Crusher Plant incorporates all the equipment together on one truck, which has high chassis, narrower body compared with other trucks, this ensure the crushing plant be easily transported on highways and moved to crushing sites, so it is able to achieve on-site crushing without material transporting from one place to another place. In addition, the lengthened plant is able to transport the final products to the motor-lorry directly. The mobile crusher plant can start to work soon even in the bumpy groud without reinstallation, so it saves more time and money than fixed crushing plant which needs to install individual equipment one by one.

| Item | Spcification |

| Max Feeding size | 340mm |

| Feeding size | 400x600mm |

| Capacity | 40-60t/h |

| Weight | 36.5t |

| Motor power | 200kw |

| Overall dimension | 16700x3500x4200mm |

| Adjustment Range | 0-60mm |

| Machine includes | hopper feeder, jaw crusher, impact crusher, vibrating screen, conveyor belts, generator, mobile chassis |

| Power supply | Generator(diesel) |

4. Working principle:

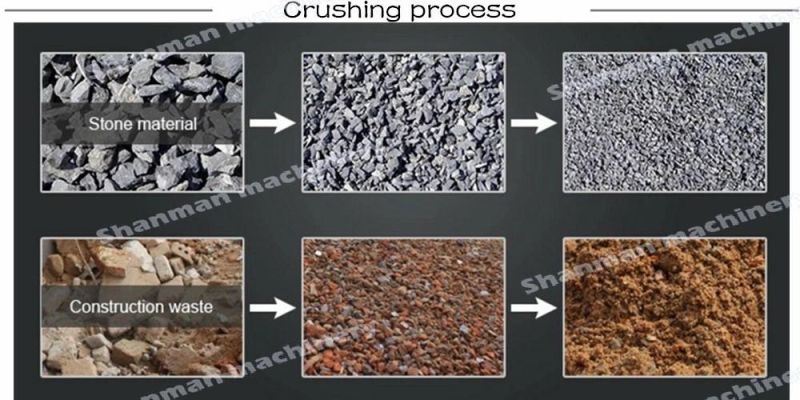

The diesel generator drives the eccentric shaft of the jaw crusher through the triangular belt and the trough wheel to make the jaw crusher move reciprocally, so as to crush the material entering the crushing chamber. The crushed stones from jaw crusher will transport to impact crusher by conveyor belt, the impact crusher will crush the stones for secondary crushing. Then the final products go to vibrating screen, the screen will sieve out different sizes of aggregates into piles. These final aggregates size can be changed according to clients request, such as 0-10-20-40mm, different final size will be different capacity.

5. Working process:

340mm stones are feeding into PE400*600 jaw crusher by hopper feeder, then the crusher will break the stones, the crushed stones are transferred to the impact crusher for secondary crushing through conveyor belt, then stones will be transferred to screen by conveyor belt, the screen will sieve our different sizes, then the final stones are piled in different sizes.

Comparing with fixed stone crusher plant, there are many advantages about mobile stone crusher plant

1. Classic mobile stone crusher is formed by a combination of several units. This causes loss of time and labor force loss.

2. New generation mobile crushing plants are designed all equipment are collected in a single platform. It can be ready for use within 1 hour and installation of plant completed, can be transported within 1 hour.

3. Through compact design, the installation can be in small spaces, without concrete foundation, getting rid of both cost and concrete.

4. When mobile stone crusher is moving or installed, the hydraulic legs are controlled to be up or down with a pressure control valve, which is more convenient.

5. It can be transported on single truck to provide ease of transportation.

6. It can be controlled by a single staff, provides operational convenience.

7. Both the generator and the electrical system can work with. Low fuel spend.

8. The above crusher can also place on the mobile crawler platform , then it have the ability to move itself .

6. Advantages- Generator diesel engine power, no need electric.

- You can use it directly after put into diesel. Easy operation.

- Simple structure, easy maintenance

- High crushing ratio, even output granularity

- High reliability, low investment

- Low noise, less dust.

- Jaw crusher have flexible capacity, you can adjust the output size from 0-60mm to meet your own final aggregates size requirement.

8.Customer visit

9. Certifications:

10. Shanman service

- Assist clients to choose the suitable machine

- Design and manufacture machines according to customer's special requirements

- The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

- Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

- Make sure goods prepared within delivery time;

- Pre-check and accept products ahead of delivery;

- Prepare documents required to help customer pass customs clearance.

- Help clients to make Project evaluation and feasibility analysis and draft solving plans.

- Provide technical engineers to guide the installation;

- Train clients worker how to operate;

- Offer spare parts at a best price for long term.

11. Packing & shipping

12.Questions you may have

Q: Are you mining machinery manufacturer?

A: Yes, we are manufacturer, we warmly welcome clients to visit our factory at anytime. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose the suitable machine?

A: To design a suitable machine, please let me know the following information:

- what kind of stone do you want to crush ? like limestone ? or granite ?

- what's the size of your stone before crush ? how many inch or mm ?

- how big capacity do you need?2t/h?10t/h?100t/h?

- what's your requirements of final product size ? how many inches or mm ?0-5mm?5-20mm? Or others?

- you only need one set of crusher or a whole crushing line? (Include the feeder ,crusher, screen, conveyor and so on)

- You need mobile crushing machine or stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: the warranty period is one year. we will supply the spare parts for you any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already build many mining projects in China & Overseas.

Q: how about the installation?A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier do the installation, supplier will provide technical engineers to guide the installation, and train buyer' workers. Buyer should take the charges for technicians and pay them salary.

Q: what is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

13. Shanman small series crusher

14. About us

Shanman Machinery Crusher Production Base is a company specializing in the production of jaw crushers, impact crushers, cone crushers, sand making machines, vibrating feeders, vibrating screens, mobile stone crushers and other crushing and screening machines. The company was founded in 2010, covers an area of 20,000 square meters, has more than 100 employees, 5 chief engineers and more than 10 after-sales service personnel, these can ensure your solution. Shanman has now become a production and export base for the crushing and screening industry.

As a production plant, we can produce crushing and screening machines according to your actual needs. Many models we develop and produce are designed and produced according to different customer requirements. You can let us know your thoughts, and professional engineers will help you.

Our mission

Carry out independent and innovative research in the design field of crushing and screening equipment and devote to the production of the most suitable equipment.

We are committed to producing high-quality and cheap machinery.

Production of machines for people in need, production of the most suitable machines

Our vision

Establish a first-class production base to inject power into the crushing and screening industry

Join hands with Shanman to create a better future.