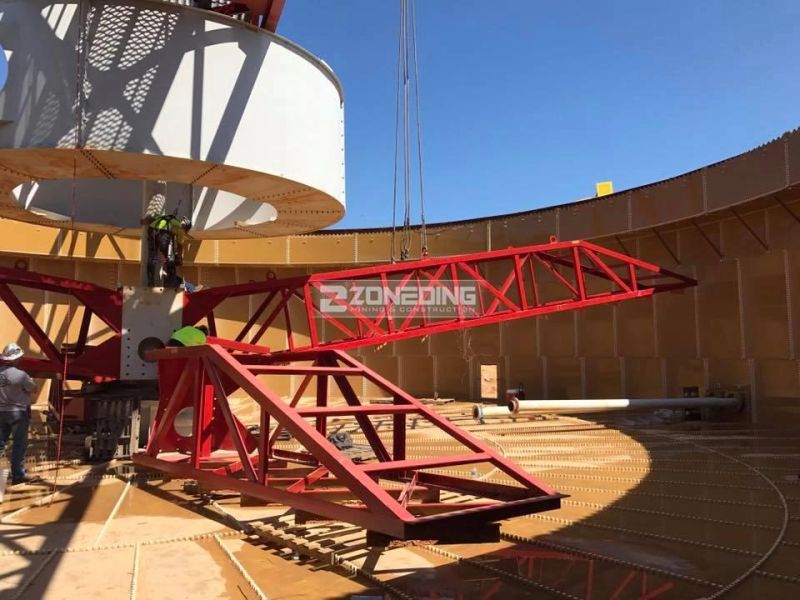

Automatic Center Drive Sludge Industrial Thickeners for Gold Plant

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd.- Type:Normal Thickener

- Motor Type:AC Motor

- Diameter:20m

- Application:Mine

- Condition:New

- Spare Parts:Provide

Base Info

- Model NO.:NZS-15

- Pool Material:Steel

- Pool:Site-Welding

- Drive Parts:Provide

- Foundation Drawing:Provide

- Installation Guide:Provide

- Trademark:zoneding

- Origin:Henan China

- Production Capacity:150 Sets,Month

Description

Basic Info.

Model NO. NZS-15 Pool Material Steel Pool Site-Welding Drive Parts Provide Foundation Drawing Provide Installation Guide Provide Trademark zoneding Origin Henan China Production Capacity 150 Sets/MonthProduct Description

Introduction:Thickener is a solid-liquid separation device based on gravity sedimentation, usually a cylindrical shallow groove with a conical bottom constructed from concrete, wood or metal welded plates as structural materials. The slurry with a solid content of 10% to 20% can be concentrated by gravity sedimentation into an underflow slurry with a solid content of 45% to 55%. With the help of the slow-running rake installed in the thickener, the thickened underflow can be made The pulp is discharged from the underflow port at the bottom of the thickener.

The upper part of the thickener produces a relatively clean clarified liquid (overflow), which is discharged from the annular chute on the top.

Thickeners are widely used in hydrometallurgy, mineral processing plants, chemical plants and other production sites that require solid-liquid enrichment and separation.

The thickener is a widely used equipment for leaching and washing in cyanide plants. It has the functions of concentration, washing and buffering. According to the different transmission modes, thickeners can be divided into two types: central transmission type and peripheral transmission type.

For the specifications of thickeners, the central transmission type is generally expressed by the inner diameter of the thickener pool, and the peripheral transmission type is expressed by the diameter of the circular track.

The central drive thickener is mainly composed of an annular tank, a rake and a transmission mechanism. The bottom of the pool is a gently inclined conical shape, and the inclination angle between the bottom surface and the horizontal plane is 6°~12°. The pool is generally made of concrete structure, and the smaller diameter can also be welded by steel plate. The upper edge of the inner wall of the pool has an overflow ring Overflow trough. The vertical shaft located in the center of the pool is connected with the rake mechanism. The rake mechanism is composed of rake arms, rake teeth and reinforcement bars. The two rake arms arranged radially are perpendicular to each other into a cross shape. In order to discharge the concentrated product deposited on the bottom of the pool through the discharge port, the rake teeth are installed on the rake arm at an inclination angle of about 30° with the rake arm, and the vertical shaft is installed in the worm wheel inner hole of the worm gear drive. Among them, the two are in a sliding fit. Due to the positioning effect of the connecting key, it can only move down the axis in the worm gear.

Main Features:

(1) Add a degassing tank to prevent solid particles from adhering to bubbles, which is like a "parachute" sedimentation phenomenon.

(2) The feed pipe is located below the liquid level to prevent gas from being brought in during feed.

(3) The feeding sleeve is moved down, and there is a receiving pan to make the feeding slurry fall evenly and steadily, effectively preventing the phenomenon of turning over caused by the residual pressure of the mine;

(4) The internal overflow weir is added to make the material flow according to the specified stroke and prevent the phenomenon of "short circuit";

(5) The overflow weir is changed into a zigzag shape, which improves the suction phenomenon of local drainage caused by the non-level overflow weir;

(6) The shape of the rake teeth is changed from a slanted line to a curved line, so that the slurry not only rakes toward the center, but also gives a "backlog" force toward the center, which makes the underflow concentration of the ore discharge high, thereby increasing the processing capacity.

Technical Parameters:

| Model | Dia. (m) | Depth (m) | Slope (°) | Circle Time (min) | Lifting Hight (mm) | Capacity (t/24h) | Driving Power (kw) | Lifting Power (kw) | Weight(t) | Note |

| NZS-1 | 1.8 | 1.8 | 8 | 2 | 160 | 5.6 | 1.1 | - | 1.24 | Manual Lift |

| NZS-3 | 3.6 | 1.8 | 8 | 2.5 | 350 | 22 | 1.1 | - | 3.2 | Manual Lift |

| NZ-3 | 3.6 | 1.8 | 8 | 2.5 | 350 | 22 | 1.1 | 0.75 | 3.2 | Auto Lift |

| NZS-6 | 6 | 3 | 8 | 3.7 | 200 | 62 | 1.1 | - | 3.7 | Manual Lift |

| NZ-6 | 6 | 3 | 8 | 3.7 | 200 | 62 | 1.1 | 0.75 | 3.7 | Auto Lift |

| NZS-9 | 9 | 3 | 8 | 4.3 | 250 | 140 | 3 | - | 5.2 | Manual Lift |

| NZ-9 | 9 | 3 | 8 | 4.3 | 250 | 140 | 3 | 1.1 | 5.2 | Auto Lift |

| NZS-12 | 12 | 3.5 | 8 | 5.2 | 250 | 140 | 3 | - | 9.5 | Manual Lift |

| NZ-12 | 12 | 3.5 | 8 | 5.2 | 250 | 140 | 3 | 1.1 | 9.5 | Auto Lift |

| NZ-15 | 15 | 4.4 | 9 | 10.4 | 400 | 350 | 5.5 | 2.2 | 21.76 | Auto Lift |

| NZ-20 | 20 | 4.4 | 9 | 10.4 | 400 | 500 | 5.5 | 2.2 | 24.5 | Auto Lift |

| NZ-24 | 24 | 4 | 9 | 15/20 | 400 | 700 | 5.5 | 2.2 | 27 | Auto Lift |

| NZ-30 | 30 | 5.1 | 9 | 13/16/20 | 400 | 384 | 7.5 | 2.2 | 34.46 | Auto Lift |

For more product, contact us freely!