Double Spiral Mineral Washer Machine for Washing Small Mining Stones

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.- Type:Spiral Separator

- Voltage:220V,380V,440V

- Weight:11680kg

- Material:Manganese Steel

- Material Feature:Wear-Resistant, Anti-Corrosion

- Certification:ISO9001:2008, ISO9001:2000, CE, SGS

Base Info

- Model NO.:Spiral Mineral Washer

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Can Be Customized According to Customer Requiremen

- Customized:Can Be Customized According to Customer Requiremen

- Condition:New

- Water Chute Length:8265mm

- Water Chute Width:1664mm

- Power:7.5kw

- Transport Package:by FCL or LCL

- Specification:Standard

- Trademark:Hengchang Screw Sand Washer

- Origin:Jiangxi Province China

- HS Code:8474100000

- Production Capacity:1000 Sets Per Year

Description

Basic Info.

Model NO. Spiral Mineral Washer Energy Saving Energy Saving Warranty 1 Year Color Can Be Customized According to Customer Requiremen Customized Can Be Customized According to Customer Requiremen Condition New Water Chute Length 8265mm Water Chute Width 1664mm Power 7.5kw Transport Package by FCL or LCL Specification Standard Trademark Hengchang Screw Sand Washer Origin Jiangxi Province China HS Code 8474100000 Production Capacity 1000 Sets Per YearProduct Description

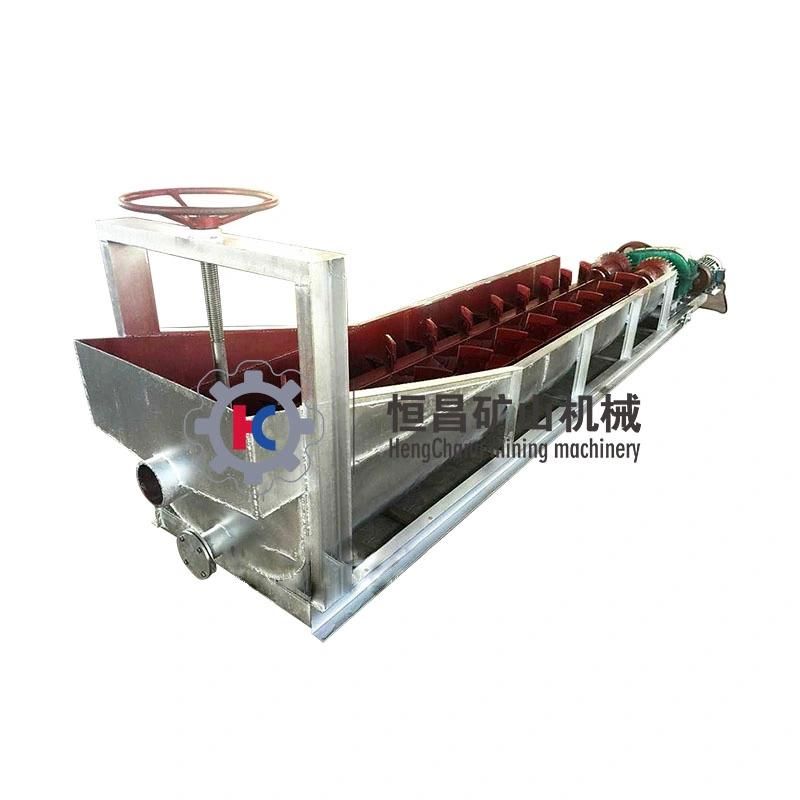

Mineral Spiral Mineral Stone Washer Machine After Crushing, the stones will also contain the mud, so the small stones can be washed in the double spiral mineral stones washer.

Mineral Spiral Mineral Stone Washer Machine After Crushing, the stones will also contain the mud, so the small stones can be washed in the double spiral mineral stones washer.

The advantages of our spiral beneficiation machine:

1. All blades are made of automobile steel plates, which are more wear-resistant and more efficient than ordinary steel plates.

2. The lower bearing has a sealing treatment, so that the industry criticism of bearing immersion corrosion can be solved.

It is similar in structure to the spiral classifier, except that the blades are discontinuous blades. This kind of ore washing machine has strong cutting and scrubbing capabilities, and has a strong ability to break up small mud balls, and is suitable for processing difficult-to-wash ores with medium-grain size and more mud. The advantage is that the production capacity is large, the washing efficiency is high, the structure of the trough type washing machine is similar to that of the general spiral classifier, that is, two shafts with stirring blades are installed in a semicircular chute, and the blades are discontinuous The shape of the paddle leaf is a spiral line. The slurry is fed from the lower end of the trough. The cement of the sludge is cut and scrubbed by the blade and washed by the high-pressure water fed from the upper end of the chute to separate the clay from the ore. The washed clay material is discharged from the overflow trough at the lower end. Coarse-grained materials are pushed by the blades and discharged from the ore discharge port at the upper end of the tank. The washing time is determined by the length of the tank, the pitch and the rotation speed of the shaft.

Working Priciple

When working, the motor passes the V-belt, reducer, and the gear reduces the speed to drive the impeller to rotate slowly. The feed trough enters the washing trough, tumbles under the impeller drive, and grinds each other to remove impurities covering the surface of the sand and stone, At the same time, it destroys the water vapor layer of impurity sand particles to facilitate dehydration; at the same time, water is added to form a strong water flow, and impurities are promptly removed Small foreign objects with small specific gravity are taken away and discharged from the overlapping mouth washing tank to complete the cleaning function. The clean gravel is carried by the blade After walking, the gravel is poured into the discharge trough from the rotating impeller to complete the cleaning of the gravel.

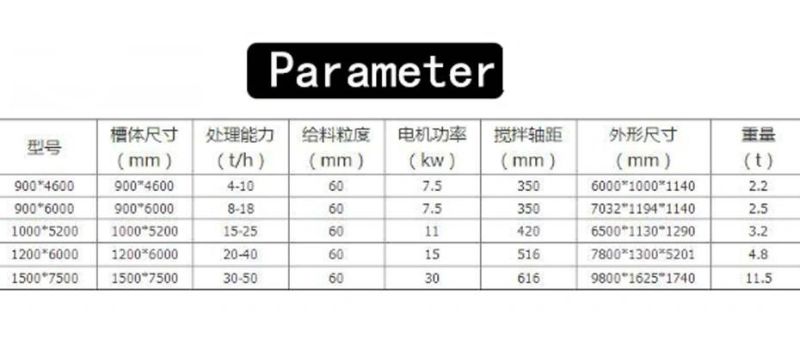

Technical Parameter of Mineral Stone Washer Machine