Ball Mill, Grinding Mill, Mining Equipment

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:110kw

- Rotationl Speed:17-19r,min

- Application:Iron, Copper, Gold, Mn etc

- Materials:Mine Ore

Base Info

- Model NO.:1500*4500

- Condition:New

- Place of Origin:Henan China (Mainland)

- Installation:Engineer Oversea Service

- Training Course:Supply

- Warranty:1year

- Drawing Document:Offer

- Recovery Rate:High

- After-Sale Service:Lifelong

- Certification:CE:Cmhn2013132313 ISO2001-2008

- Transport Package:Export Standard Container

- Specification:International Standard

- Trademark:HengXing

- Origin:Henan Province China

- Production Capacity:100tph

Description

Basic Info.

Model NO. 1500*4500 Condition New Place of Origin Henan China (Mainland) Installation Engineer Oversea Service Training Course Supply Warranty 1year Drawing Document Offer Recovery Rate High After-Sale Service Lifelong Certification CE:Cmhn2013132313 ISO2001-2008 Transport Package Export Standard Container Specification International Standard Trademark HengXing Origin Henan Province China Production Capacity 100tphProduct Description

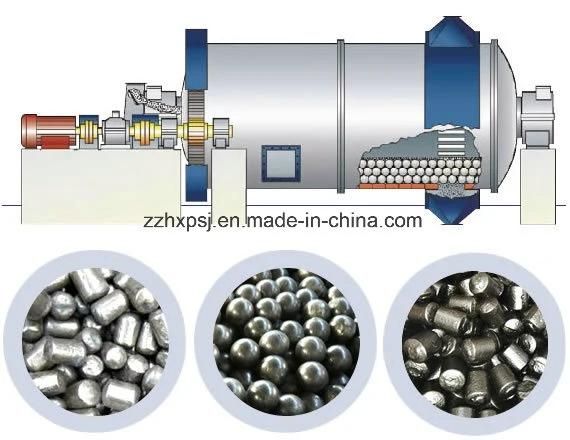

Ball Mill, Grinding Mill, Mining EquipmentBall mill is used to grind the metallic mineral ores such as gold ore, copper ore, iron ore, etc..the hot-sale models are including 600×700, 900×1200, 1500×1800, 1800×2000, 3200×4600, and the capaicty of ball mill is 0.65-615t/h. Tell us your requrement such as the capaicty you want to reach and the materials you want to process, our technical people will prepare the quote and price list for you asap.Wet ball mill is used widely in the ore beneficiation industry, as well as the building material industry such as glass.During the producing phase, the material and water are mixed together to grind in the ball mill. Under the effect of the flowing water, the material will get a better flow ability so the processing capacity will be higher.

We usually control the granularity of the final product with spiral classifier, hydraulic cyclone or high frequency screen etc. The product is slurry which can make fully preparation for the following concentrating and other procedure. Wet ball mill as the most important machine of ore beneficiation field, the performance of ball mill determines the whole producing plant quality. The common wet ball mill are grate type and overflow type. We should choose the suitable type according to the specific condition.

1. Wet ball mill is used widely in the ore beneficiation industry, as well as the building material industry such as glass.

2. During the producing phase, the material and water are mixed together to grind in the ball mill.

3. Under the effect of the flowing water, the material will get a better flow ability so the processing capacity will be higher.

4. We usually control the granularity of the final product with spiral classifier, hydraulic cyclone or high frequency screen etc.

5. The product is slurry which can make fully preparation for the following concentrating and other procedure.

6. Wet ball mill as the most important machine of ore beneficiation field, the performance of ball mill determines the whole producing plant quality.

7. The common wet ball mill are grate type and overflow type. We should choose the suitable type according to the specific condition.

ball mill working principle :

This machine is a horizontal type cylinder rotary device and outside the cylinder there is drive gear which drives the cylinder to rotate during the working process. Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many steel balls with different specifications. The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are flat lining board, and in the lining board there are steel balls to further grind the materials. Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding process.

ball mill technical specifications :

| Model | Rotation speed(r/min) | Ball load(t) | Feed size(mm) | Discharge size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

| 900× 2100 | 36-38 | 1.5 | 0-15 | 0.075-0.8 | 0.5-1.3 | 18.5 | 4.9 |

| 1200× 2800 | 36 | 3.5 | 0-20 | 0.075-0.8 | 1.2-3.7 | 37 | 12.5 |

| 1500× 3500 | 29.7 | 7.5 | 0-25 | 0.075-0.8 | 3.3-8.8 | 75 | 16.5 |

| 1830× 3600 | 25.4 | 13 | 0-25 | 0.075-0.8 | 4-8 | 130 | 30 |

| 2100× 3600 | 21 | 23 | 0-25 | 0.075-0.8 | 4.5-33 | 180 | 37 |

| 2400× 3000 | 21 | 23 | 0-25 | 0.075-0.8 | 7-50 | 245 | 54 |

| 2700× 3600 | 20.7 | 40 | 0-25 | 0.075-0.8 | 12-75 | 400 | 86 |

| 3200× 3600 | 20.2 | 52 | 0-25 | 0.075-0.8 | According to processing conditions | 600 | 122 |

Ball mill working site :

ball mill shipping :

You are welcome to our company for visiting and business cooperation. We will provide you the best services and most favorable price. For more introduction, please contact with me !

Contact:

Sara

Mobile phone : 0086137 8347 1727

website: zzhxpsj.en.made-in-china.com