Continuous Wet Overflow Ball Mill Machine for Gold Ore

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:22KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Materials:Gold

Base Info

- Model NO.:900*1800, 1200*2400, 1500*4500, 1500*5700

- Condition:New

- Input Size:25mm and Down

- Certificate:ISO9001-2008

- Color:on Requst

- Spare Parts:Supply for Whole Life

- Bearing:Roller or Bush Bearing in Choice

- Warranty:1 Year Apart From Wearing Parts

- Capacity(T/H):1-50tph

- Output Size:0-400mesh(Adjustable)

- Discharge System:Overflow or Grate Type in Choice

- Mining Object:Metallic and Non-Metallic Ore Excavator

- Transport Package:Standard Container

- Specification:National standard

- Trademark:hengxing

- Origin:Henan, China

- Production Capacity:1-50tph

Description

Basic Info.

Model NO. 900*1800, 1200*2400, 1500*4500, 1500*5700 Condition New Input Size 25mm and Down Certificate ISO9001-2008 Color on Requst Spare Parts Supply for Whole Life Bearing Roller or Bush Bearing in Choice Warranty 1 Year Apart From Wearing Parts Capacity(T/H) 1-50tph Output Size 0-400mesh(Adjustable) Discharge System Overflow or Grate Type in Choice Mining Object Metallic and Non-Metallic Ore Excavator Transport Package Standard Container Specification National standard Trademark hengxing Origin Henan, China Production Capacity 1-50tphProduct Description

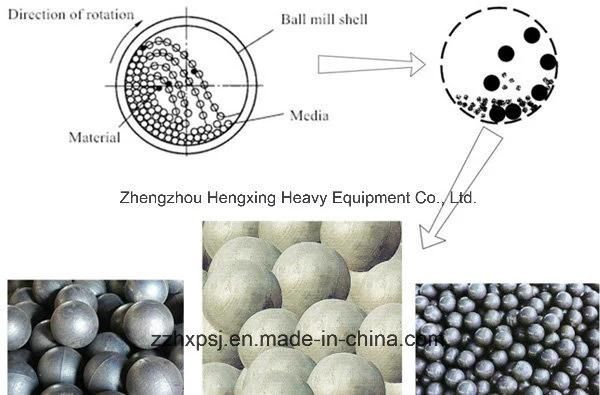

Continuous Wet Overflow Ball Mill Machine For Gold Ore The ball mill is a key equipment for regrinding. Ball mill is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

ball mill has following features: 1.The product size can be adjusted; 2.The system run stable;3.There is no wearing parts;4.Widely used in powder making.

Working Principle of the Ball Mill:Materials shall be evenly charged through quill shaft in feeding device into the first bin, which has step or waved lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding.Materials after crushed in the first bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding.Powder shall be discharged from discharging grating, ending the milling process.

Ball Mill Technical Parameters:

| Model | shaft rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity(t/h) | Power(KW) | Weight(T) |

| Φ 900 × 1800 | 38 | 1.5 | ≤ 20 | 0.075 -0.89 | 0.65 -2 | 18.5 | 3.6 |

| Φ 900 × 2100 | 38 | 1.3-1.4 | ≤ 15 | 0.075 -0.83 | 0.7 -3.5 | 18.5 | 3.9 |

| Φ 900 × 3000 | 38 | 2.7 | ≤ 20 | 0.075 -0.89 | 1.1-3.5 | 22 | 4.5 |

| Φ 1200 × 2400 | 32 | 3.8 | ≤ 25 | 0.0745-0.6 | 1.5-4.8 | 30 | 11.5 |

| Φ 1200 × 2800 | 32 | 3.3-3.5 | ≤ 25 | 0.0745-0.6 | 2-6 | 30 | 13 |

| Φ 1200 × 4500 | 32 | 7 | ≤ 25 | 0.074 -0.4 | 1.6-5.8 | 45 | 13.8 |

| Φ 1500 × 3000 | 27 | 8 | ≤ 25 | 0.074 -0.4 | 2-5 | 75 | 17 |

| Φ 1500 × 3500 | 27 | 6.75 -6.4 | ≤ 25 | 0.075 -0.4 | 3-7 | 75 | 17.5 |

| Φ 1500 × 4500 | 27 | 14 | ≤ 25 | 0.074 -0.4 | 3.5-12 | 110 | 21 |

| Φ 1500 × 5700 | 27 | 15 | ≤ 25 | 0.074 -0.4 | 3.5-8 | 115 | 24.7 |

| Φ 1830 × 3000 | 24 | 18 | ≤ 25 | 0.074 -0.4 | 4-10 | 130 | 28 |

| Φ 1800 × 3600 | 24 | 10.6 -11.35 | ≤ 25 | 0.075 -0.4 | 5-22 | 130 | 33.5 |

| Φ 1830 × 7000 | 24 | 25 | ≤ 25 | 0.074 -0.4 | 7.5-17 | 210 | 36 |

| Φ 2100 × 3600 | 22 | 14-15.2 | ≤ 25 | 0.075 -0.4 | 15-36 | 370 | 46.8 |

| Φ 2200 × 5500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 10-20 | 210 | 48.5 |

| Φ 2200 × 6500 | 21 | 31 | ≤ 25 | 0.074 -0.4 | 14-26 | 380 | 52.8 |

| Φ 2200 × 7500 | 21 | 33 | ≤ 25 | 0.074 -0.4 | 16-29 | 380 | 56 |

| Φ 2400 × 3000 | 20.6 | 15.5 -16.6 | ≤ 25 | 0.075 -0.4 | 22-24 | 245 | 59 |

| Φ 2400 × 4500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 8.5-60 | 380 | 65 |

| Φ 2700 × 3600 | 20.6 | 39 | ≤ 25 | 0.074 -0.4 | 12-70 | 400 | 91.3 |

| Φ 2700 × 4000 | 20.7 | 40 | ≤ 25 | 0.074 -0.4 | 12-80 | 400 | 94 |

| Φ 2700 × 4500 | 20.7 | 48 | ≤ 25 | 0.074 -0.4 | 12-90 | 430 | 102 |

| Φ 3200 × 4500 | 18 | 65 | ≤ 25 | 0.075 -0.4 | according to the technics | 800 | 137 |

Contact:Ms Sara Pang

Contact:Ms Sara Pang