High Quality Jaw Crusher for Limestone Crushing Plant

Nanjing Sinonine Heavy Industry Science & Technology Co., Ltd.- Type:Jaw Crusher

- Motor Type:AC Motor

- Motor Power:5.5-160kw

- Application:Mine and Metallurgy

- Materials:Granite, Limestone, Hard Rock, Gold Ore, Iron Ore

- Outlet Size:Adjustable10-200mm

Base Info

- Model NO.:PE,PEX

- Inlet Size:125-1000mm

- Condition:New

- Energy Consumption:Energy Saving

- Certification:ISO, CE, BV, GB

- Transport Package:Nude and Wooden Box

- Trademark:sinonine

- Origin:China

- HS Code:8474209000

- Production Capacity:50set,Year

Description

Basic Info.

Model NO. PE/PEX Inlet Size 125-1000mm Condition New Energy Consumption Energy Saving Certification ISO, CE, BV, GB Transport Package Nude and Wooden Box Trademark sinonine Origin China HS Code 8474209000 Production Capacity 50set/YearProduct Description

Limestone Jaw Crushers is of single toggle type with features of simple structure, easy maintenance, stable function, low operation cost, great crushing ratio. It is used widely in mine, metallurgy, construction, road, railway, hydro-electric, and chemistry. It is suitable for the primary or secondary crush of large rock with compressive resistance no more than 320MPa. PE type is used for primary crushing, and PEX type is used for secondary and fine crushing.

Features of jaw crusher

1. Deep crashing cavity, no unreachable corner in cavity, higher feeding capacity and productivity.

2. Great crushing ratio, homogeneous output size.

3. Discharging adjustment by shim, reliable and convenient, broad range of adjustment, more flexibility.

4. Safe and reliable lubrication system, easy change spare parts, less effort in maintenance.

5. Simple structure, reliable work, low cost in operation.

6. Less energy consumption: single machine can reduce 15%-30% energy consumption, and the whole system can reduce by a half.

7. Broad range of discharging adjustment meets variable requirement of customers.

8. Low noise, little dust.

Working principle of jaw crusher

Powered by electrical motor, movable jaw is set in reciprocating movement at predetermined track through the transmission system of driving wheel, Vee-belt, and eccentric roll-driving shaft. The material is crushed in the cavity composed by fixed jaw plate, movable plate, and side protecting plate, and discharged the end product from the bottom discharge opening.This series jaw crusher adopts curve-movement compression way to crush the material. electric motor drives belt and belt wheel to set the movable plate in moving up and down through eccentric shaft. When the movable jaw rises, the angle formed by toggle and movable plate will be wider, and the jaw plate will be pushed approaching the fixed plate. In this way, the materials are crushed through compressing, grinding, and abrading. When the movable plate descends, the angle formed by toggle and movable plate will become narrower. Pulled by rod and spring, the movable plate will move apart from toggle, so the crushed materials can be discharged from the bottom of the crushing cavity. Consecutive movement of motor drives the movable plate in circular crushing and discharge to realize large-quantity production.

Specification of jaw crusher

| Model | Size of feed Opening (mm) | Discharge range Opening (mm) | Max. feed size (mm) | Capacity (t/h) | Power (kw) | Overall dimension (L×W×H)(mm) | Weight (kg) |

| PE150×250 | 150×250 | 10 ~40 | 125 | 2~6 | 5.5 | 875×745×935 | 1100 |

| PE200×350 | 200×350 | 10 ~50 | 160 | 6~10 | 7.5 | 1080×1060×1088 | 1600 |

| PE250×400 | 250×400 | 20 ~60 | 210 | 8~16 | 15 | 1108×1090×1392 | 1850 |

| PE400×600 | 400×600 | 40~100 | 350 | 14~36 | 30 | 1650×1748×1520 | 5800 |

| PE500×750 | 500×750 | 50~120 | 400 | 30 ~80 | 45 | 1900×1876×1821 | 9000 |

| PE600×900 | 600×900 | 75~200 | 480 | 56~192 | 75 | 2280×2245×2320 | 18700 |

| PE750×1060 | 750×1060 | 80-180 | 630 | 72-198 | 110 | 2526x2410x2780 | 28000 |

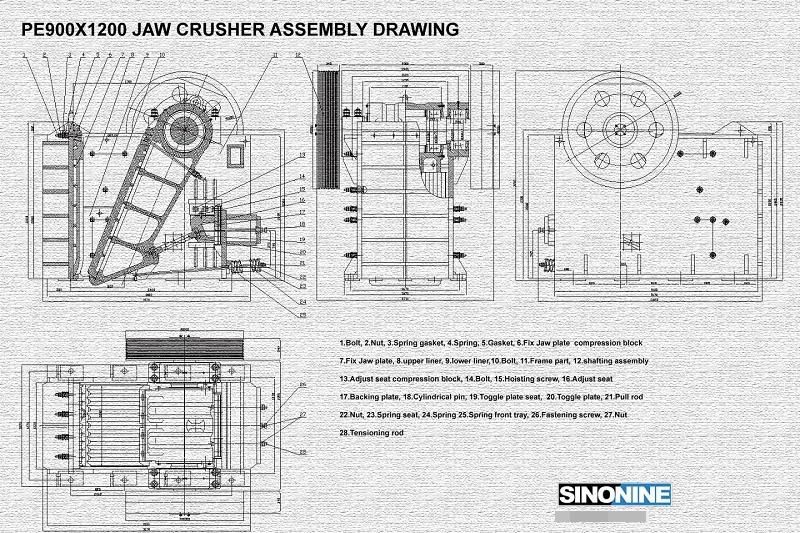

| PE900×1200 | 900×1200 | 95~265 | 750 | 186~398 | 110 | 3335×3182×3025 | 50000 |

| PE1000×1200 | 1000×1200 | 130~280 | 850 | 190~420 | 132 | 3889x3282x3530 | 52000 |

| PE1200×1500 | 1200×1500 | 160~320 | 1000 | 280~700 | 160 | 3800×3040×4150 | 82000 |

| PEX150×750 | 150×750 | 10 ~40 | 120 | 8~25 | 15 | 1210×1572×1045 | 2800 |

| PEX250×750 | 250×750 | 20 ~50 | 210 | 12-40 | 30 | 1450×1785×1260 | 5500 |

| PEX250×1000 | 250×1000 | 20 ~50 | 210 | 15 ~50 | 30 | 1550×1990×1370 | 6500 |

| PEX250×1200 | 250×1200 | 20 ~60 | 210 | 20 ~60 | 45 | 1650×2170×1465 | 9000 |

| PEX300×1300 | 300×1300 | 25 ~65 | 250 | 20 ~80 | 55 | 1980×2456×1740 | 11500 |