Cone Crusher Spare Parts Eccentric Assembly Assy Suit Metso Nordberg HP100 HP200

Jiangsu Hyton Mechanical Equipment Co., Ltd.- Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Forging

- Material:Cast Iron

- Transport Package:Standard Packing

Base Info

- Model NO.:HP100 HP200

- Specification:Standard Size

- Trademark:Hyton

- Origin:Jiangsu China

- HS Code:84749000

- Production Capacity:30000 Ton Per Year

Description

Basic Info.

Model NO. HP100 HP200 Specification Standard Size Trademark Hyton Origin Jiangsu China HS Code 84749000 Production Capacity 30000 Ton Per YearProduct Description

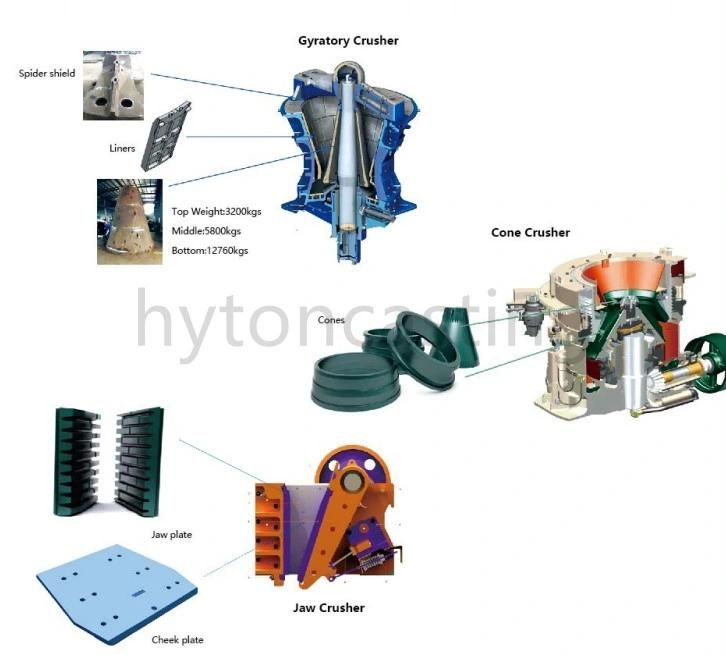

Cone Crusher Spare Parts Eccentric Assembly Assy Suit Metso Nordberg HP100 HP200Product DescriptionHP Cone Crusher Spare Parts Eccentric Assembly Apply to Metso Nordberg Hyton (Jiangsu) supply the one stop service for almost all the spare and wear parts, mainly include : Main Frame, Adjustment Ring Head Assy, Bowl, Drive Gear, Counterweight assy, Shaft, Pitman, Bronze Bushing, Pump,Tramp Release Cylinder, Protection, Bushing, Bearing, Seals Spring, Wedge, Toggle Plate, and Etc.

Having the proper parts supply on-hand is critical to your operations. With decades of experience in designing, producing and supplying parts - you can count on us.

With multiple fabrication options and upgrades to choose from, Metso's cone crusher spare parts are eliminting risk that the replaced part becomes the weak point in your crusher. They offer stable production without unexpected downtime. Metso HP series Tramp Release Cylinder Assembly, it was one of the key parts of the crusher, Hyton have more than 20 years experience supply the service for Metso hp crusher spare parts, we guarantee the 100% same life time and qualityas original parts

Company Profile

Located in the New Material Industrial Park, Bowang High-Tech Zone, Ma' anshan City, the company covers an area of 90 Squarekilometer and currently has more than 300 employees.

Hyton Heavy Industry Technology Development Co.Ltd is a high-tech enterprise andspecialization new enterprise which specializing in the production of high-manganesesteel wear-resistant castings, high-chromium wear-resistant castings, carbon alloy steelcastings and others spare parts for Crushing and Screening and Drilling Equipment.

Hyton widely supply the Spare Parts of Jaw Crusher , Cone Crusher ,Gyratory Crusher.

The company is equipped with lost molding production line and lost castingproduction line imported from FATA Company in ltaly, Inductotherm Vacuum Degassing Furnace(USA ), Foseco Casting Technolo-gy(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze moldingmachine Disa production line, horizontal molding line and self-control lost casting production line in China,the most advanced sandtreatment system in China.

With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatmentproduction lines, the company can annually produce 30,000 tons of various wear-resisting castings.

Packing & Shipping

After goods packaged well, we need only 1 day ship good to shanghai port, which means that most of the spare parts you bought from Hyton, it will get your port within 30 days all around the world if ship by sea.

After Service

In the past 15 years, Hyton has always adhered to the principle of our mission "Serving the world with technology and service", adhere to the customer site, adhere to the scientific and pragmatic concept, taking the technology as the core driving force, constantly strive to provide customers with the best quality and efient service, and be well received by the industry.

We has established a set of perfect services structure. It is a "one -stop" work style "without worry service" system involved pre-sale, sells, post- sale as well as the technical support entire proess. Has formed a new business form Mainly include conventional technical support, user operation training, spare parts refurbishment, equipment and spare parts renting, equipment and spare parts leasehold, group user spare parts consignment cooperation mode, equipment escrow, production contract andother new business forms at the core.

FAQ

1.Q: Are you a foundry or trading company?

A: Our factory since 2004, we equip with complete facilities, all production process from manufacturing to testing isfinished in our own factory.

2.Q:What kind of products do you make?

A: We specialize in mining machinery spare and wear parts, widely suit for Jaw Crusher, Cone Crusher, VSI crusher, Impact Crusher...

3 Q:What kind of material do you offer?

A:High manganese steel, high chrome iron, alloy steel are currently the most regular material of us.

4.Q:What is your time of delivery?

A:Our lead time is generally 1~2 weeks for spare parts, 3~4 weeks days for wear parts.

5.Q:Do you offer the supporting service for technology and engineering ?

A:Yes. Our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

6. Q:How to test your quanlity?

A:We will show you material inspection and measurement inspection after fininsh the goods, at the same time we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first, all the good business relationship all from test and trust.