China Made Zpc1512 200-300 Tph Heavy Duty Hammer Crusher/Crushing Machine and Equipment

Qingzhou Yongli Mining and Dredging Machinery Co., Ltd.- Type:Hammer Crusher

- Motor Type:AC Motor

- Motor Power:264kw

- Application:Quarry,Cement,Mining,Coal Preparation,Chemistry

- Materials:Limestone

- Outlet Size:40-130mm

Base Info

- Model NO.:ZPC1512

- Inlet Size:≤600mm

- Condition:New

- Warranty:Support

- After-sales Service:Support

- Usage:Mine,Construction,Road,Cement,Quarry

- Deal Capacity:200-300tph

- Weight:18 Tons

- Rotor Diameter:1.5m

- Chamber Width:1.2m

- Transport Package:Nude Packing

- Specification:ZPC1512

- Trademark:Fukang

- Origin:Shandong, China

- HS Code:8474209000

- Production Capacity:1000 PCS, Per Year

Description

Basic Info.

Model NO. ZPC1512 Inlet Size ≤600mm Condition New Warranty Support After-sales Service Support Usage Mine,Construction,Road,Cement,Quarry Deal Capacity 200-300tph Weight 18 Tons Rotor Diameter 1.5m Chamber Width 1.2m Transport Package Nude Packing Specification ZPC1512 Trademark Fukang Origin Shandong, China HS Code 8474209000 Production Capacity 1000 PCS/ Per YearProduct Description

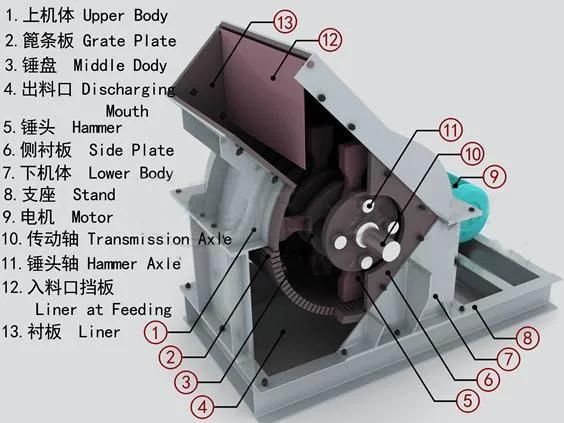

China Made ZPC1512 200-300 TPH Heavy duty hammer crusher/crushing machine and equipment1.Brief Introduction

This series of crushers adopts advanced production technology to realize one-time feeding and forming, and it has the characteristics of high efficiency, energy saving and environmental protection. The finished material can be adjusted according to the needs, and the specifications of coarse, medium and fine are complete: no flakes, no smooth bodies, multi-angles and multi-edges, which can effectively ensure the compressive strength. Especially suitable for highway, construction and large-scale engineering materials. This crusher is an alternative to the old jaw crusher and plate hammer crusher. This series of products are suitable for various medium-hard materials and brittle materials, such as limestone, coal and other materials. The crusher is mainly used in cement, mining, coal preparation, power generation, chemical and building materials industries.

2. Product charaterristics

a. High efficiency and low operation cost

b. Flexible capacity

c. Simple structure and easy to operate

d. Over loading protection

e. Easy replacement of wearing parts

f. Long service life

g. High reliability

h. Wide ranges of choices

i. Alternative ordinary and hydraulic types

3.Structural design

4.How it works

Hammer crusher hammer back with a tray mounted on a horizontal axis, mainly by the base, disc, cover, shaft, pin, hammer, bearings, discharge grate bar joists, eccentric suspension axis, spiral and other components. Raw material is fed through the feeding mouth into crushing cavity, high-speed hammer violently shaken and thrown to the ladder arrangement liner, more violently crushed,crushing majority reached the desired size of the finished product that is calculated according to the unloading gap, The stone also impact with the hammer plate, they also impact each other. So the crushing energy and place was being fully utilized. Single-directional rotating rotor hammer crusher multi-row structure. All casing wall lined with manganese steel liner. Crusher rotor is keyed to the disc number only on the spindle formed.

5.Techncial Specification

| Model | Max Feeding size(mm) | Discharge Material size(mm) | Production Capacity (t/h) | Motor Power (kw) | Equipment Weight (ton) |

| ZPC1512 | ≤600 | 40-130 | 200-300 | 132-4 pole*2 pcs | 18 |

| ZPC1516 | ≤600 | 40-130 | 250-400 | 160--4 pole*2 pcs | 24 |

| ZPC1518 | ≤600 | 40-130 | 300-450 | 185--4 pole*2 pcs | 35 |

| ZPC1618 | ≤700 | 50-150 | 350-500 | 220--4 pole*2 pcs | 38 |

| ZPC1620 | ≤700 | 50-150 | 350-600 | 250--4 pole*2 pcs | 45 |

a.Our products are standard design and the delivery time will be shorter than customized products.

b. We can send our engineers to your worksite to help you with the installation, trail operation and train your workers to operate the whole crushing plant.

c. We can also supply the engineers for one years' after-sales mainteance.

d. We could supply the spare parts for the whole crushing plant.

e. We can recovery back the whole crushing plant based on the equipment's condition.

7. Picture Shows