Wet Magnetite Ores Concentration and Heavy Media Operations Processing Equipment

Fushun Ejet Magnetic Equipment Co., Ltd.- Type:Magnetic Separator

- Voltage:According Require

- Weight:5T

- Material:Stainless Steel

- Material Feature:Wearable

- Certification:CE

Base Info

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:as Required

- Customized:Customized

- Condition:New

- Item:Drum Magnetic Separator for Dense Media Separation

- Characteristic for Hdms Separator:Maximum Efficiency Iron Mineral Ore Separation

- Nagnetic Drum Rotation:12~14 Rpm for Wet Type Mineral Ore Benificiation E

- Magnetic Intensity:180,300 Mt for Slurry Mineral

- Application in Heavy Media Operations:Magnetite or Ferrosilicon Recovery

- Application in Mineral Processing:Ferrous and Weakly Magnetic Concentration

- Transport Package:Packing in Nude in Container with Waterproof

- Specification:wood-based composite panels

- Trademark:EJET

- Origin:Liaoning Province, China

- Production Capacity:50set,Month

Description

Basic Info.

Energy Saving Energy Saving Warranty 1 Year Color as Required Customized Customized Condition New Item Drum Magnetic Separator for Dense Media Separation Characteristic for Hdms Separator Maximum Efficiency Iron Mineral Ore Separation Nagnetic Drum Rotation 12~14 Rpm for Wet Type Mineral Ore Benificiation E Magnetic Intensity 180/300 Mt for Slurry Mineral Application in Heavy Media Operations Magnetite or Ferrosilicon Recovery Application in Mineral Processing Ferrous and Weakly Magnetic Concentration Transport Package Packing in Nude in Container with Waterproof Specification wood-based composite panels Trademark EJET Origin Liaoning Province, China Production Capacity 50set/MonthProduct Description

wet drum magnetite or ferrosilicon recovery in dense media operation

Product DescriptionWet drums in heavy media applications provide continuous recovery of magnetite or ferrosilicon.

besides this HMDS Wet type Magnetic mineral ore beneficiate equipment is widely used for fine-grained iron magnetite ores purification or separation.

With the development and expansion of heavy media processing technique, drum separator for heavy media processing is widely used in the separation of various kinds of iron ores and coal ores.

Fine iron magnetite separator are requisite equipment for concentration plant of iron mine, suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as hematite, magnetite, pyrrhotite, calcined ore and ilmenite and can also be used for removing iron from the materials such as coal, non-metal ore and building material. the performance and steadiness plays a vital part in the economic benefit of ore beneficiation .

Performance Features for Wet type Magnetic mineral slurry beneficiate1. For depleted iron ore roughing after coarse/medium crushing, can exclude waste rock to improve ore quality and reduce load for next process.

2. For hematite in a closed reduction roasting operation, select out raw ore that is not fully restored, return it and then burn again.

3. For the ceramic industry, remove mixed iron from porcelain mud to improve the quality of ceramic products.4. For burning coal, foundry sand, refractory and other industries requires iron removal. Working priciple of Wet Drums magnetic separator for Heavy Media Duty

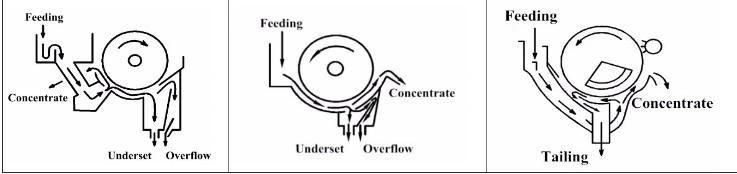

Two basic tank styles are offered. The drum rotates in the same direction as the slurry flow in the concurrent tank style. The slurry enters the feedbox and is channeled underneath the submerged drum. The slurry then flows into the magnetic field generated by the drum. The magnetite is attracted by the magnetic field, collected on the drum surface, and rotated out of the slurry flow. This tank style results in a very clean magnetic product.

Heavy Media Content Rcycling Rate 87-130kg/m3 >99.7% 130-260kg/m3 >99.8% >260kg/m3 >99.9%

A long term research in different performances required by different procedure, we developed wet type heavy media drum separator specially for different procedure. According to specific need, customers can choose from many kinds of magnetic separators with different surface magnetic intensity.

| CTN type countcurrent | CTS type cocurrent | CTB type countcurrent |

| Grain-Size(mm): 0~0.6 Applications: Heavy medium recovery | Grain-Size(mm): 0~6 Applications: Tailing Recycling | Grain-Size(mm): 0~0.6 Applications: Concentration of mine |

Our Services

With well-equipped professional engineers and strong technical force, Ejet speciliazed in various metal separation industries since 2006 , we cooperate with superior suppliers (Nord &Schneider)to keep our quality,the test of materials is free if you are interested in our machine, strict quality checked for every machine before packing, engineers available to service machinery overseas, inaddition, there is not only after sales service support, but also technology support, "keep improing, persuing excellence" would be keep forever.

Our main products are eddy current separator, suspended magnetic separator,magnetic mineral processing equipemnt ,lifting magnets,etc equipement that related to magnetic separation industries .

With good quality, reasonable prices,our products are extensively used in solid waste treatment, metallurgical mine, power plants, coal mining and other industries. The products have been exported to the United States, Canada, Japan and Australia.

We welcome new and old customers to contact us for future business relationships and mutual success!

In order to give you the responsible quotation, pls kindly inform us the following details:

1. What kind of material you are going to deal with?

2.What's the size of the materials?

3. What's the producing capacity you are going to achieve?

Most suitable machine would be recomended to you according to your informations.

please Contact with Miss Jasmine Song :