Pilot Scale X-ray Sorting of Tungsten Ore/Wolframite/Antimony Ore/Tin Ore/Lead-Zinc ...

SLon Magnetic Separator Co., Ltd.- Type:Auxiliary Equipment

- Voltage:Customized

- Weight:>10T

- Material:Stainless Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2015

Base Info

- Model NO.:SIXS1400

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Lifetime

- Capacity:50~90t,H

- Power:60kw

- Range:10~80

- Channel:120

- Installation:Site Installation

- After-Sale Service:Lifetime

- Transport Package:Seaworthy Packing

- Specification:SIXS1400

- Trademark:SLon

- Origin:China

- HS Code:8479899990

- Production Capacity:20sets,Month

Description

Parameters of X-ray SortingType Range Power/kw Capacity(t/h) Channels/per Dimensions (L*W*H) /mm SIXS1200 Φ10-Φ80 50 30-70 100 8250*2100*2100 SIXS1400 Φ10-Φ80 60 50-90 120 8250*2300*2300 SIXS1600 Φ10-Φ80 70 70-110 140 8250*2500*2500

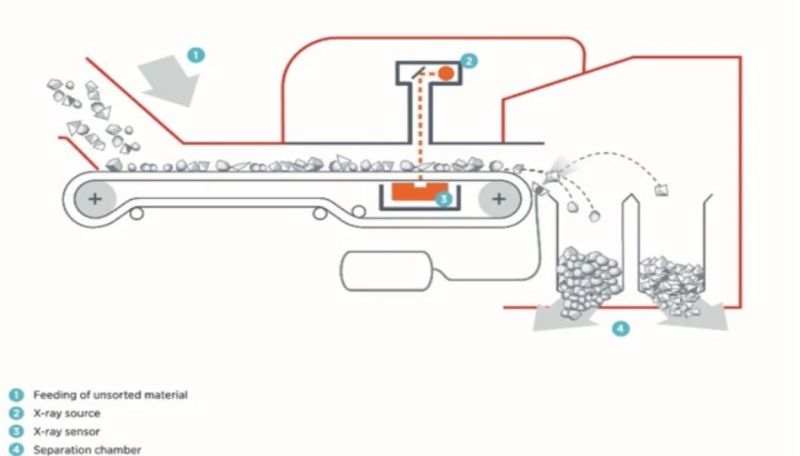

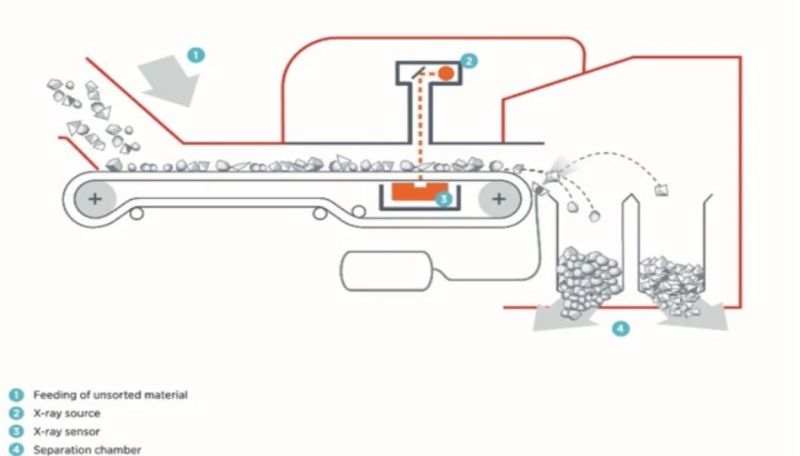

Working Principle:

X-ray sorting is based on a planar projection of X-ray attenuation of a particle stream. These particles are distributed either on a chute or fast conveyor, and they are scanned and evaluated individually while passing. Hard X-ray radiation is emitted on one side of the material stream, and an image is recorded by a line scan detector on the other side. Following fig shows the working principle of a belt-type XRT sorter. The particles are fed to the machine via vibrating feeder, diverted down a shaped chute, stabilized on the high-speed conveyor, detected by the X-ray system, analyzed and classified in the sorter control, and rejected depending on the classification of each individual particles. The capacity of XRT sorting machines varies with particle size, bulk density of the feed and specific sorting tasks. XRT-sorters have been successfully installed for diamond concentration, processing of chromite, coal, iron ore, limestone, phosphate ore, talc, tin ore, tungsten ore and more.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.

Working Principle:

X-ray sorting is based on a planar projection of X-ray attenuation of a particle stream. These particles are distributed either on a chute or fast conveyor, and they are scanned and evaluated individually while passing. Hard X-ray radiation is emitted on one side of the material stream, and an image is recorded by a line scan detector on the other side. Following fig shows the working principle of a belt-type XRT sorter. The particles are fed to the machine via vibrating feeder, diverted down a shaped chute, stabilized on the high-speed conveyor, detected by the X-ray system, analyzed and classified in the sorter control, and rejected depending on the classification of each individual particles. The capacity of XRT sorting machines varies with particle size, bulk density of the feed and specific sorting tasks. XRT-sorters have been successfully installed for diamond concentration, processing of chromite, coal, iron ore, limestone, phosphate ore, talc, tin ore, tungsten ore and more.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.