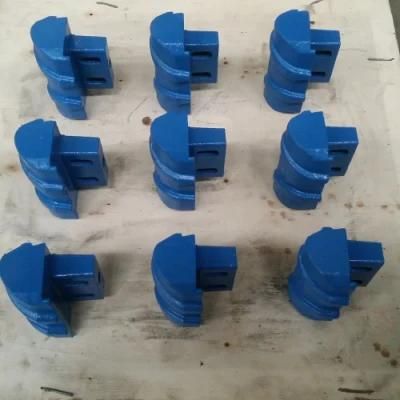

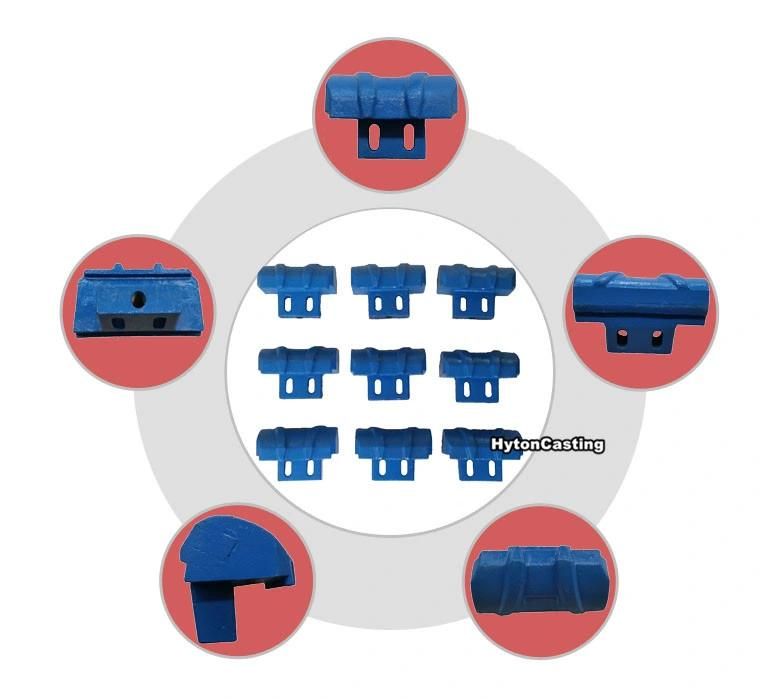

Apply to VSI Crusher Wear Parts CV229 Back up Tip Set 488.0368-901

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.- Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008, Ce, ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:Carbide

- Color:Customerized

Base Info

- Model NO.:CV229

- Advantage:High-Efficiency

- Application:Quarry

- Market:Global

- Packing:The Wooden Packing Materials

- Machine Type:Vertical Shaft Impact Crusher

- Transport Package:Standard Packing

- Specification:standard size

- Trademark:Hyton

- Origin:Jiangsu China

- HS Code:84749000

- Production Capacity:30000 Ton Per Year

Description

Basic Info.

Model NO. CV229 Advantage High-Efficiency Application Quarry Market Global Packing The Wooden Packing Materials Machine Type Vertical Shaft Impact Crusher Transport Package Standard Packing Specification standard size Trademark Hyton Origin Jiangsu China HS Code 84749000 Production Capacity 30000 Ton Per YearProduct Description

Overview VSI crusher, also called vertical shaft impact crusher, or sand making machine, is used for producing the fine sand or reshaping the fine sand, follwing the impact crusher or cone crusher. The famous VSI machine is metso barmac or Sandvik, and there are also some famous Chinese brand, like SBM, Bailike,Liming, etc. The VSI spare parts mainly include cavity wear plate, rotor tip, lower wear plate, upper wear plate, distributor plate, etc.

HytonCasting is the factory affiliated with the foundary factory to supply the VSI sand making spare parts. we can offer most of the spare parts for the famous VSI brands in the market with product code. And if you can offer the drawing, we can also do OEM for the customers.

Suit For Sandvik Machine: CV117 CV128 CV129 CV217 CV228 CV229 RP108 RP109

Aslo Suit For Other Brands:

Metso Barmac:B5100SE B6150SE B7150SE B8100SE B9100SE

Terex:CRJ3042 CRJ3255 CRJ3750

Product Descripition

Rotor Assembly Mainly Include:

Rotor Tip Set, Back Up tip set ,Feed Tube,Top Wear Plate,Bottom Wear Plate,Trial Plate,Wear Plate Lower,Wear Plate Upper,Distributor Plate,Cavity Wear Plate...etc

Hyton(Jiangsu) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Jiangsu Province,Nantong City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton(Jiangsu) has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer .Established in June 2004, the company is now undertaking a National Torch Program Project, and five of its patented products have been honored as the "New High Tech Product" of Jiangsu Province two of which have been listed into the New Products Program of Jiangsu Province. The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Jiangsu Province", the company has beenappraised as a "Trustworthy" unit of Jiangsu Province for many consecutive years.

Our Advantages

20 years experience ,all parts can suit the crusher well.

Hyton guarantee the 100% replace the original parts

Certified by ISO system certification

Large amount of stock for customer with competitive price.

OEM service available.

Hyton's Guarantee to all of our customers :

-All of the castings finish must go along with the Metal Inspection and Dimension Inspection .

-Hyton will always have the responsibility of all the products from hyton in the market , will service a "24+3"service rules (After get the request from customer , The after-service department of hyton myst supply the feedback solution within 24 hours ,and must get Consistent scheme amd solve the promblem within 3 days .

-Hyton have a professional after-service team can promise service all over the world ,service including the Installation Guide ,Measurement at site ,Inspection and etc .

Packing and Shipping

After goods packaged well , we need only 1 day ship good to shanghai port ,which means that most of the spare parts you bought from Hyton ,it will get your port within 30 days all around the world if ship by sea.

FAQ

1.Q: Are you a foundry or trading company?

A: Our factory since 2004, We equip with complete facilities, all production process from manufacturing to testing is finished in our own factory.

2.Q:What kind of products do you make?

A: We specialize in mining machinery spare and wear parts, widely suit for Jaw Crusher,Cone Crusher,VSI crusher,Impact Crusher...

3.Q:What kind of material do you offer?

A:High manganese steel, high chrome iron, alloy steel are currently the most regular material of us.

4.Q:What is your time of delivery?

A:Our lead time is generally 1~2 weeks for spare parts,3~4 weeks days for wear parts.

5.Q:Do you offer the supporting service for technology and engineering ?

A: Yes. our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

6.Q:How to test your quanlity?

A:We will show you material inspection and measurement inspection after fininsh the goods,at the same time,we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first,all the good business relationship all from test and trust