Bucket Wheel Sand Washer Machine for Sand Making Plant

Xinxiang Great Wall Machinery Co., Ltd.- Type:Bucket Sand Washer

- Capacity:150-200t,h

- Water Consumption:Customized

- Speed of Screw:Customized

- Motor Type:AC Motor

- Motor Power:7.5KW

Base Info

- Model NO.:Sand Washer

- Certification:ISO, CE

- Rotation Speed:0.8-1.2 r,min

- Wheel Bucket Diameter:Customized

- Screw Diameter:Customized

- Input Size:0-10mm

- Material:Granite, Marble, Basalt, Limestone, Quartz, Pebbl

- Transport Package:Transport Package

- Specification:15-200TPH

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:15-200tph

Description

Basic Info.

Model NO. Sand Washer Certification ISO, CE Rotation Speed 0.8-1.2 r/min Wheel Bucket Diameter Customized Screw Diameter Customized Input Size 0-10mm Material Granite, Marble, Basalt, Limestone, Quartz, Pebbl Transport Package Transport Package Specification 15-200TPH Trademark CHAENG Origin Henan Production Capacity 15-200tphProduct Description

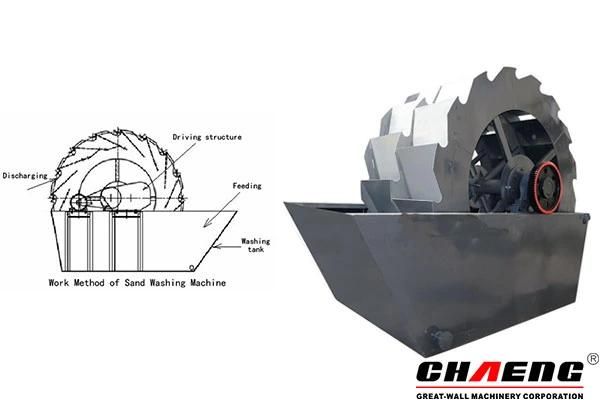

Inroduction of sand washer/sand washing machineThe sand washer is specially designed for washing, grading and dewatering of sandstone and river pebbles. Its novel sealing structure and adjustable overflow plate ensure high efficiency and durability, which is the best choice for upgrading domestic sand washing equipment.

Working principle of sand washer/sand washing machine

When sand washer works, the power plant drives the impeller to slowly rotate after slowing down through the V-shaped belt, reducer, and gear. And sandstone materials go into the washing chute from the material cabin, and are rolled by the impeller, and then grind with each other to remove the impurities covering the surface of the sand and stone materials, and at the same time break the moisture layer coated on the sand particles for the purpose of dehydration. In the meantime, add water in it to form a strong water flow to timely wash away the impurities and foreign matters with small specific gravity, and discharge them from the overflow port to complete the washing process.

Specification of sand washer/sand washing machine

| Model | Wheel Diameter(mm) | Speed(r/min) | Max. Input Size(mm) | Washing Capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) | Weight(kg) |

|---|---|---|---|---|---|---|---|

| XS2210 | 2200 | 2.5 | ≤10 | 15~30 | 4 | 3180×1955×2350 | 2260 |

| XS2610 | 2600 | 2.5 | ≤10 | 20~50 | 5.5 | 3515×2070×2672 | 2500 |

| XS2810 | 2800 | 1.2 | ≤10 | 50~80 | 11 | 3964×3014×2895 | 3200 |

| XS2815 | 2800 | 1.17 | ≤10 | 60~100 | 11 | 3964×2137×2895 | 3580 |

| XS3016 | 3000 | 1.2 | ≤10 | 70~110 | 11 | 4169×3456×3055 | 3850 |

| XS3210 | 3200 | 1 | ≤10 | 80~120 | 15 | 4340×2760×3349 | 3950 |

| XS3215 | 3200 | 1.17 | ≤10 | 95~130 | 15 | 4346×2198×3345 | 4185 |

| XS3610 | 3600 | 1 | ≤10 | 110~200 | 15 | 4580×3218×3600 | 4600 |

Advantages of sand washer/sand washing machine

1.The transmission device is separated from water and water material to avoid be damaged by submerging of water, sand and contaminants, which decreases the malfunction ratio;

2.The wheel impeller is well designed with high washing purity, big output, and less power consumption;

3.Simplified structure, stable operation

About Us

Xinxiang Great Wall Machinery Co., Ltd, founded in 1958, was originally a township collective enterprise and was converted into a private enterprise in 2002. Xinxiang Great Wall now has 2 main sectors, 4 plant areas and 8 companies, and it covers equipment for building material, large steel casting, industrial waste slag grinding, industrial plastic electronics, high-end oil equipment, car-free carrier platform etc, with total assets of one billion RBM, covering an area of 700,000 square meter, owning more than 2000 employees.

Besides doing a good job in green building material equipment manufacturing, at the same time, Xinxiang Great wall Xinxiang Great Wall Machinery carries out transformation and upgrade tightly around energy conservation and environmental protection industry.Achieving excellent results in metallurgical slag recycling industry, Xinxiang Great Wall Machinery cooperated with China king of slag treatment Ji Gengxin,Shanghai Bao steel, Ningbo steel etc, built and run a project of GGBFS/ steel slag composite powder production line in Ningbo Steel, make Ningbo Steel become the first domestic steel company that industrial waste slag is zero discharge, and has come to the forefront in the steel slag resource recycling. In the meanwhile, cooperating with Zhejiang University to develop new equipment to use waste gas drying sludge, which is expected to become the mainstream sludge drying equipment. Self-developed submersible direct drive screw pump system, integrated environmental protection, safety, energy conservation and intelligence, makes it become the research & development manufacture base of pump oil extraction equipment without rod in China, and the only one equipment manufacturing enterprises who participates in making the standards. Along with the national "The Belt and Road" strategy, and actively go out, our products are exported to the US, Germany, Russia, Japan, Korea, Indonesia, Uzbekistan, Pakistan, Vietnam and more than 60 countries and regions, and has achieved long-term cooperation with Sinoma, Shanghai Baosteel, Korea POSCO and other well-known enterprises at home and abroad, and becomes industrial waste slag resource recycling national high-tech enterprises. Xinxiang Great Wall has achieved gorgeous turn from a single equipment supplier to the grinding system integrated service provider of friendly environment builders.