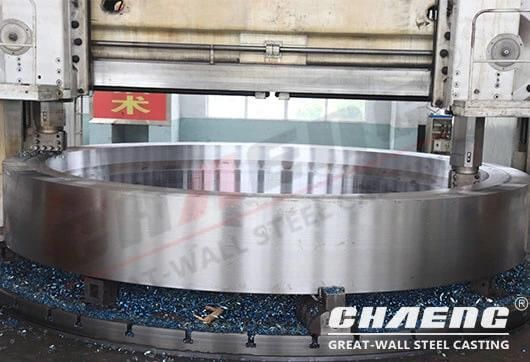

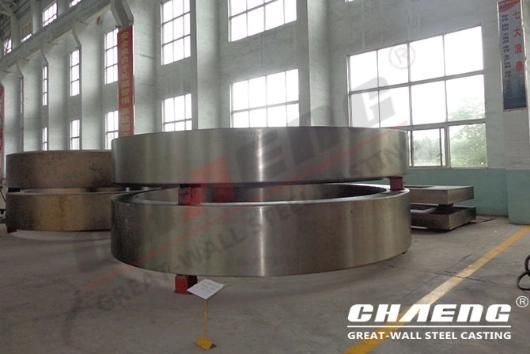

Rotary Kiln Spare Parts Rolling Ring

Xinxiang Great Wall Machinery Co., Ltd.- Certification:ISO9001:2015

- Standard:JIS, GB, ASTM, DIN

- Manufacturing Process:Casting

- Material:Cast Steel

- Color:as Required

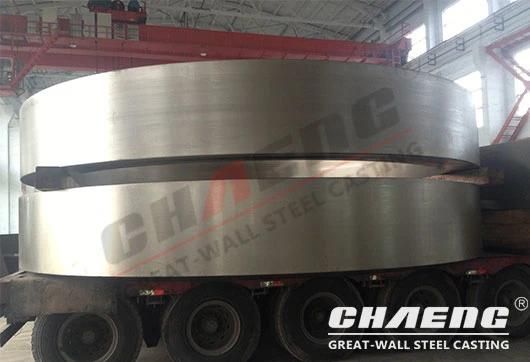

- Transport Package:Suitable for Sea Transportation

Base Info

- Model NO.:customized

- Specification:Customzied

- Trademark:CHAENG

- Origin:China

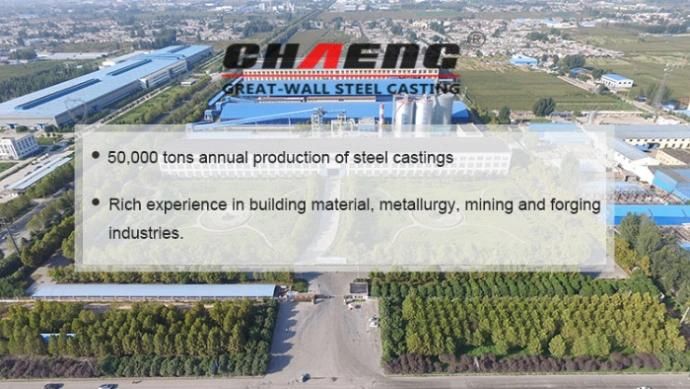

- Production Capacity:50000 Tons,Year

Description

Our rotary kiln rolling ring's advantages:

1. High strength and good durability

2. Advanced double medium quenching process

3. High quenching hardness

4. Good wear resistance

5. Simple structure and easy to adjust and repair

CHAENG rotary kiln rolling ring are widely used:

Excellent product quality makes CHAENG rotary kiln rolling ring sold to Henan, Guangxi, Zhejiang and other provinces, and also to many well-known overseas enterprises in Italy, Turkey, Chicago, Kazakhstan and others.

For Example:

In 2014, a Guangxi building material company purchased φ4.0×60m rotary kiln and φ2.4×4.75m coal mill from Great Wall Machinery, the matched kiln rolling rings were manufactured by us.

In August 2014, the kiln rolling ring produced by CHAENG passes the acceptance of Zhejiang Tongli Company, and got highly praise.

In 2012, CHAENG kiln rolling ring was delivered to Italy.

Why choose CHAENG rotary kiln rolling ring?

1. Cost-effective

CHAENG has the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as "high cost-effective steel castings manufacturer".

2. Fast delivery

CHAENG has strong technical teams, detailed production scheduling, wide range of raw materials purchase channels, and perfect logistics delivery system, making efforts to achieve as fast delivery period as required.

3. Strong production capacity, fast delivery

CHAENG is equipped with complete casting, machining and testing equipment, and has mature casting process and technical teams. It can produce steel castings up to 150 tons per piece, and the annual capacity reaches 50,000 tons, to ensure high quality and fast delivery for customers.

About CHAENG

Xinxiang Great Wall Casting Co,Ltd (CHAENG), located at National Sustainable Development Experience Area, Mengzhuang Town, Huixian City, Henan Province, is an integrated foundry enterprise which involves in research, manufacturing, processing and assembly.

With strong casting, processing and assembly capabilities, the company can provide custmers with one-stop solutions for all kinds of high-end building materials equipment matching cast steel parts including 150 ton-per-piece large carbon steel castings, manganese steel castings and high alloy steel castings, etc, from optimization design, analysis and simulation, product casting, component processing, component assembly, to finished product delivery, covering industries of building materials machinery, metallurgy industry, water conservancy project, chemical industry, forging equipment, ceramic industry, ship parts, etc. It is the support service supplier of world-renowned high-end building materials equipment manufacturers, as well as the supplier of world-renowned steel companies. Its products are exported to more than 60 countries and regions including the United States, Germany, France, Italy, India, Indonesia, South Korea, Turkey, etc.