Excavator Spare Parts Bucket Tooth Bucket Teeth

Tangshan Weilang Trading Co., Ltd.- Certification:ISO 9001:2008

- Standard:GB

- Surface Treatment:Black or Silver

- Manufacturing Process:Forging

- Material:42CrMo, 30crmnsi, etc

- Hardness:47-52HRC

Base Info

- Model NO.:According to the drawing

- Material Density:7.85g

- Weight:5-20kg,PC

- Application:Crawler, Mining and Enegy, Construction, etc

- Transport Package:Seaworthy Packing

- Specification:As per the drawing

- Trademark:Weilang

- Origin:China, Hebei

- HS Code:84834090

- Production Capacity:3000 Pieces Per Month

Description

Basic Info.

Model NO. According to the drawing Material Density 7.85g Weight 5-20kg/PC Application Crawler, Mining and Enegy, Construction, etc Transport Package Seaworthy Packing Specification As per the drawing Trademark Weilang Origin China, Hebei HS Code 84834090 Production Capacity 3000 Pieces Per MonthProduct Description

Product IntroductionProduct Series:

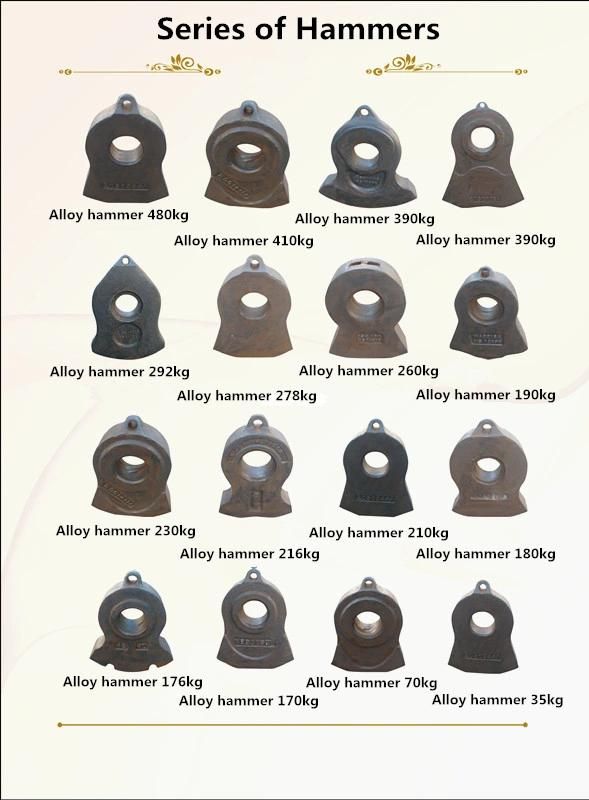

1.Series of high manganese steel

They are the wear-resisting materials that are mainly used in metallurgy,mining and crushing equipment, including ordinary high manganese steel,modified high manganese steel,super-high manganese steel,multi-component alloy intensely processed high manganese steel and magnet high aluminum steel lining plates.

2. Series of medium and low alloy steel

These products are mainly uesd in the lining plates for power plants,coal plants,xement factories and some mining ball mills,characterized with good adaptability,non-deforming,non-breaking and twice the longevity of high manganese steel.

3.Series of high chromium cast iron

These products are mainly used in the crushing equipment or matallurgy,mining and cement sectors,suitable for medium impact casting.With favorable cost performance and sound wear resistance,they are divided into four groups according to the service conditions:KmBCr15,KmTBCr20,KmTBCr26 and compound type.

4.Series of compound wear-resisting products

Hardfacing wear-resistance technique and bimetal compound casting technique are adopted to make high strength wear-resisting products,with the characteristics of being easy to process and strong wear-resisting ability.

Product Display

We can supply all kinds of forgings according to customer's requirements with different designs and materials. For example, forged roller shafts, forged pipe moulds, forged steel blocks for die and moulds, forged gears, forged round steel and son. They are mainly used for rolling mill machiney, mine machinery, chemical and petroleum industries, wind turbine industry, shipbuilding industry and so on.

We can supply all kinds of forgings according to customer's requirements with different designs and materials. For example, forged roller shafts, forged pipe moulds, forged steel blocks for die and moulds, forged gears, forged round steel and son. They are mainly used for rolling mill machiney, mine machinery, chemical and petroleum industries, wind turbine industry, shipbuilding industry and so on.Production Process

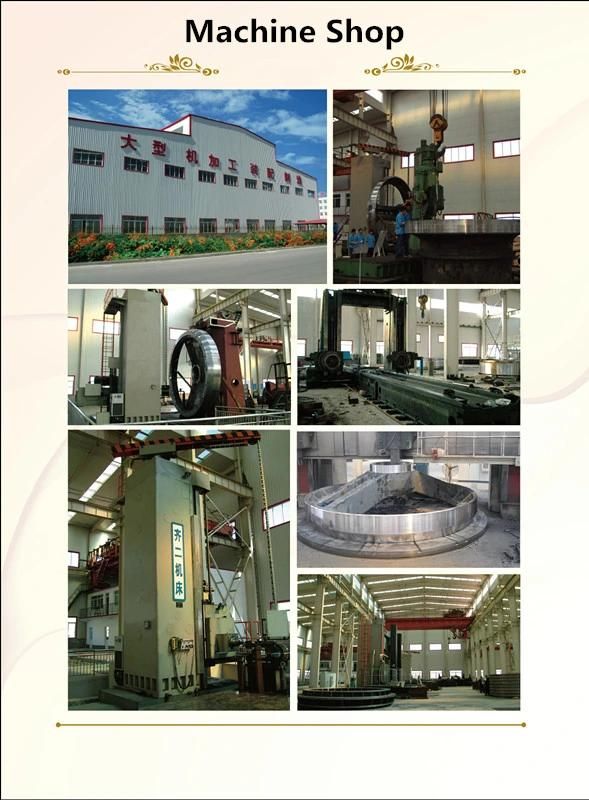

Machine Shop

Inspection Equipment

Welcome you visit our plant and start our cooperation!

Service:

1. Perfect rolling mill solutions including rolling passes design, production line setup, and workshop layout according to customer's requirements.

2. Sophisticated rolling mill stands and auxiliary equipments/spare parts used in the rolling mill production line. (Such as roller box, gearbox reduction, coil laying head, vertical and side loops, flying shears, chopping shears and gripping shears, pinch roll machine and so on)

3. Technical services and post-sale technical supports.

4. Professional engineers available for overseas installation and maintenance.

Contact us:

If you have interest,please do not hesitate to contact me.Pls send the drawing,technical requirements to us by email.

Looking forward to receiving your inquiry and reply.Thank you.