High Recovery Rate Gravity Separator Concentrator Gold Mining Machine Spiral Chute ...

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.- Type:Gravity Separator

- Voltage:380V

- Weight:Customized

- Material:Fiberglass

- Material Feature:Wear-Resisting

- Certification:ISO9001:2008

Base Info

- Model NO.:BLL-900 Spiral Chute

- Energy Saving:No Power

- Warranty:1 Year

- Color:Customized

- Customized:Customized

- Condition:New

- Name:Chrome Wash Plant with Spiral Chute

- Capacity:2-10 Tph

- Lead Time:10 Working Days

- Spiral Chute in Stock:Check with Us

- Installation:Teaching Video

- Working Principle:Gravity Separating

- Recovery Rate:Around 80%

- Application:Chrome, Tantanium, Tin Ore...

- Transport Package:Steel Frame

- Specification:Standard

- Trademark:hengchang spiral chute

- Origin:Jiangxi, China

- HS Code:8474100000

- Production Capacity:50000 Sets Per Year

Description

So What's the type of your minerals? Click here to get a Solution.

2. Introduce of Spiral chute separator

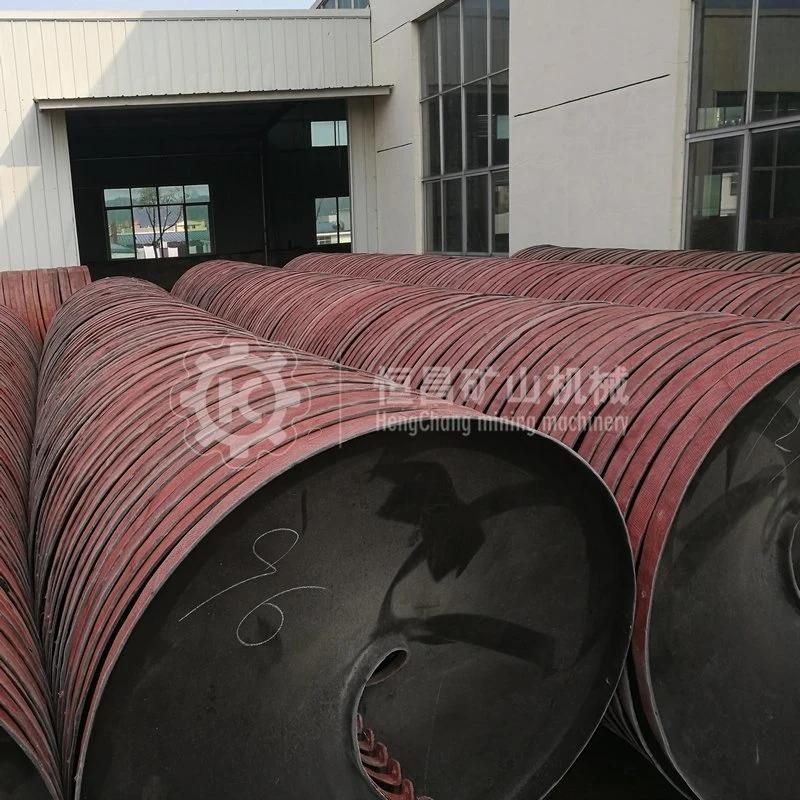

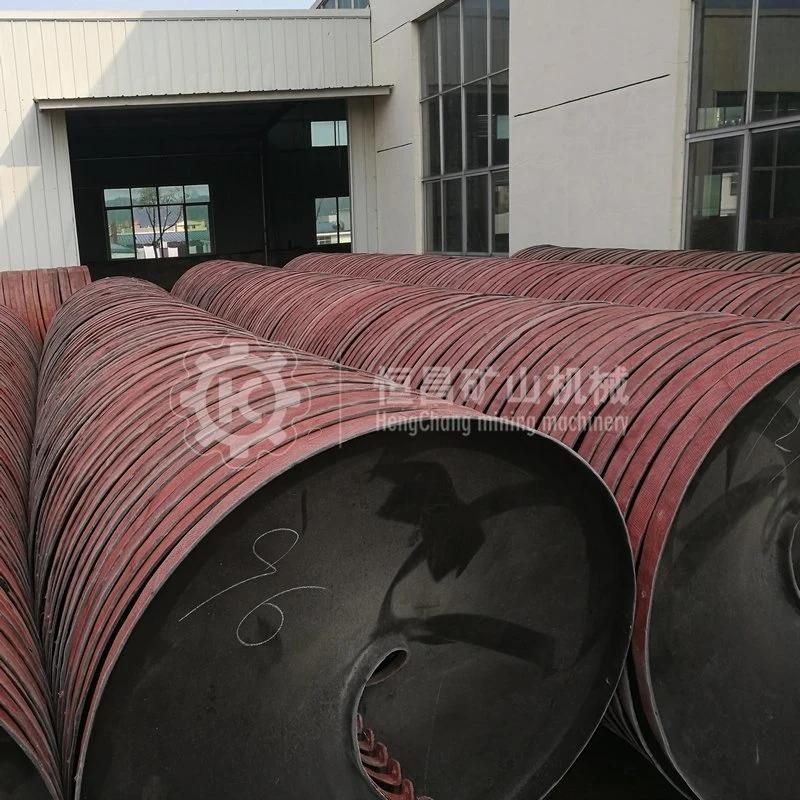

Spiral separator chutes are made of fiberglass lined with wear-resistant polyurethane and corundum cover, which makes the spiral chutes are wearable.

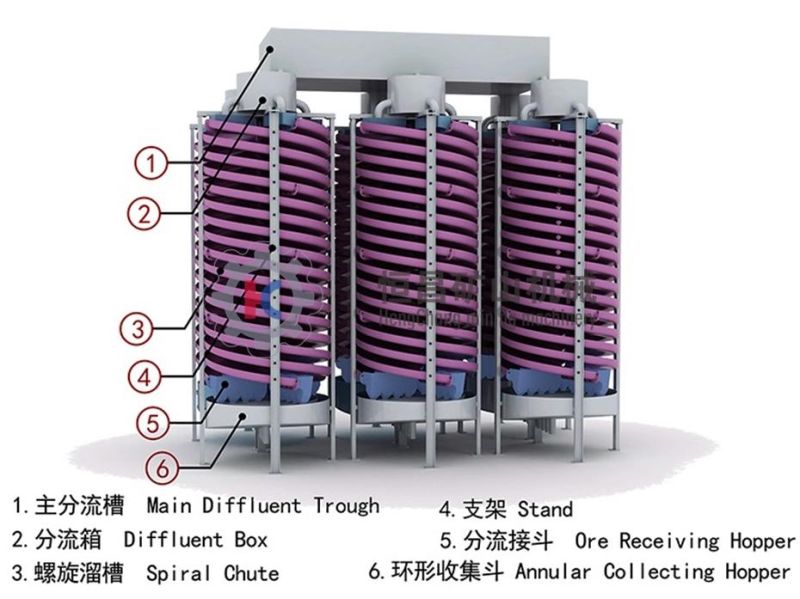

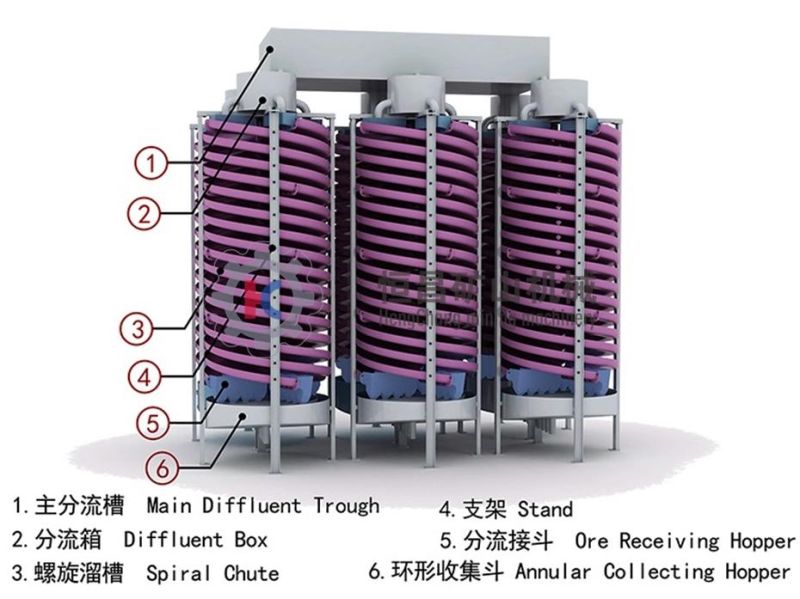

3. Parts of spiral chutes

Top of the spiral chutes spirals the bottom of spiral chutes

Top of the spiral chutes spirals the bottom of spiral chutes

4. How do the spiral chutes wash minerals?

Vertical installed the spiral chutes, fixed them by the iron frame or wood in a suitable position. The sand is sent to the two feeding ports on the top of the spiral chutes by the sand pump, and adjust the density of the slurry ores. The slurry naturally was fed from the high to the low, and an inertial centrifugal force is generated in the rotating inclined flow velocity.

According to the difference in the specific gravity, particle size, and shape of the ore sand, the gravity of the cyclone is passed With the action of centrifugal force, the ore and sand are separated. The concentrate flows into the concentrate hopper and is connected with the pipeline. The tailings flow into the tailing bucket and connected to the sand tank by pipeline, and then discharged by the sand pump. The whole process of mineral processing is completed.

5. Advantage of the spiral chutes

1. Take a small space, process large capacity.

The spiral chute occupies a small area and has a large processing capacity;

2.Moisture, rust, and corrosion resistance

Anti-rust, anti-corrosion, lightweight;

3.Reasonable structure:

Reasonable structure, simple installation, and easy operation;

4.no need power:

It has strong adaptability to the fluctuation of feed rate, concentration, particle size, and grade, and has no noise.

5.The sorting index was stable

The operation conditions of the spiral chute (such as feed particle size, pulp concentration, etc.) are not harsh, and the separation index is relatively stable;

6.Stable performance.

It is stable in mineral processing, can get concentrate, middling, and tailings (in special cases, it can be divided into 4 kinds of ores), large treatment capacity, high efficiency, high concentration ratio, high recovery rate, and reliable operation.

6. Case Analysis

Mineral: Tin ores

Process: Firstly use the spiral chutes to select the tailings, then use the spiral chutes and shaker table to rough select the coarse particle, and the last step to remove the sulfur ores and Arsenite.

Grade of Tin concentrate: 47.61%

Recovery of tin: 75.71%

Step 1: Using Spiral chutes can remove 60% tailings, the coarse tin concentrate grade can be 1.23% and the recovery rate of tin can be 89.21%. Successfully achieve the purpose of preliminary collection and removing the tailings.

Step 2: Using spiral chutes and shaking tables to select the coarse concentrate, which can get 24.47% grade of tin, and recovery 81.99% of tin concentrate from shaker tables.

7. How to install?

Contact us to get the PDF File and video for installing spiral chutes. 8. About our factory:

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. is located in No.3 Chuangye Road. Guzhang Industrial Park. Shicheng County. Ganzhou City. Jiangxi Province. China. Our company is engaged in the mineral processing equipment research, development, design, and production for many years history has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up a good reputation. And mainly the manufacture of the products like a Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

We manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten, lead. zinc. tin. molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile, diamonds, other precious metals and precious metals mine, and for the flotation colored black metal, precious metals, and other minerals. And we have export qualifications, our products sell well all over the world for several years, especially exported to Brazil. India. Indonesia.South Africa. Somalia, Philippines. Malaysia. Sudan, Nigeria. Iran, Russia, Ghana. Kazakhstan Kyrgyzstan.Cambodia, Vietnam, Korea, Mongolia, and other countries.

9. FAQQ: Are you a trading company or manufacturer?

If you have another question, pls feel free to contact us

2. Introduce of Spiral chute separator

Spiral separator chutes are made of fiberglass lined with wear-resistant polyurethane and corundum cover, which makes the spiral chutes are wearable.

3. Parts of spiral chutes

Top of the spiral chutes spirals the bottom of spiral chutes

Top of the spiral chutes spirals the bottom of spiral chutes4. How do the spiral chutes wash minerals?

Vertical installed the spiral chutes, fixed them by the iron frame or wood in a suitable position. The sand is sent to the two feeding ports on the top of the spiral chutes by the sand pump, and adjust the density of the slurry ores. The slurry naturally was fed from the high to the low, and an inertial centrifugal force is generated in the rotating inclined flow velocity.

According to the difference in the specific gravity, particle size, and shape of the ore sand, the gravity of the cyclone is passed With the action of centrifugal force, the ore and sand are separated. The concentrate flows into the concentrate hopper and is connected with the pipeline. The tailings flow into the tailing bucket and connected to the sand tank by pipeline, and then discharged by the sand pump. The whole process of mineral processing is completed.

5. Advantage of the spiral chutes

1. Take a small space, process large capacity.

The spiral chute occupies a small area and has a large processing capacity;

2.Moisture, rust, and corrosion resistance

Anti-rust, anti-corrosion, lightweight;

3.Reasonable structure:

Reasonable structure, simple installation, and easy operation;

4.no need power:

It has strong adaptability to the fluctuation of feed rate, concentration, particle size, and grade, and has no noise.

5.The sorting index was stable

The operation conditions of the spiral chute (such as feed particle size, pulp concentration, etc.) are not harsh, and the separation index is relatively stable;

6.Stable performance.

It is stable in mineral processing, can get concentrate, middling, and tailings (in special cases, it can be divided into 4 kinds of ores), large treatment capacity, high efficiency, high concentration ratio, high recovery rate, and reliable operation.

6. Case Analysis

Mineral: Tin ores

Process: Firstly use the spiral chutes to select the tailings, then use the spiral chutes and shaker table to rough select the coarse particle, and the last step to remove the sulfur ores and Arsenite.

Grade of Tin concentrate: 47.61%

Recovery of tin: 75.71%

Step 1: Using Spiral chutes can remove 60% tailings, the coarse tin concentrate grade can be 1.23% and the recovery rate of tin can be 89.21%. Successfully achieve the purpose of preliminary collection and removing the tailings.

Step 2: Using spiral chutes and shaking tables to select the coarse concentrate, which can get 24.47% grade of tin, and recovery 81.99% of tin concentrate from shaker tables.

7. How to install?

Contact us to get the PDF File and video for installing spiral chutes. 8. About our factory:

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. is located in No.3 Chuangye Road. Guzhang Industrial Park. Shicheng County. Ganzhou City. Jiangxi Province. China. Our company is engaged in the mineral processing equipment research, development, design, and production for many years history has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up a good reputation. And mainly the manufacture of the products like a Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

We manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten, lead. zinc. tin. molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile, diamonds, other precious metals and precious metals mine, and for the flotation colored black metal, precious metals, and other minerals. And we have export qualifications, our products sell well all over the world for several years, especially exported to Brazil. India. Indonesia.South Africa. Somalia, Philippines. Malaysia. Sudan, Nigeria. Iran, Russia, Ghana. Kazakhstan Kyrgyzstan.Cambodia, Vietnam, Korea, Mongolia, and other countries.

9. FAQ

Q: Are you a trading company or manufacturer?

A: We are a factory.not dealer. Direct factory sale makes the price more competitive.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.Q: What are your terms of payment?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us