Nordberg Mining Crusher Jaw Spare Parts Jaw Plate Tooth Plate Suit Metso C110

Jiangsu Hyton Mechanical Equipment Co., Ltd.- Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Industry Quarry:Ore Mining

- Usage:Jaw Crusher Wear Parts

Base Info

- Model NO.:C110

- Drawing:Original,Customized

- Color:as Customer′s Request

- Size:Customized

- Advantage:High-Efficiency

- Guarantee:Same as Original

- Condition:New

- Market:Global

- Machine Mode:C95 C96 C100

- Description:Jaw Plate Tooth Plate

- MOQ:1 PCS

- Quality:100% Original

- Transport Package:Standard Packing

- Specification:Standard Size

- Trademark:Hyton

- Origin:Jiangsu China

- HS Code:84749000

- Production Capacity:30000 Ton Per Year

Description

Basic Info.

Model NO. C110 Drawing Original/Customized Color as Customer′s Request Size Customized Advantage High-Efficiency Guarantee Same as Original Condition New Market Global Machine Mode C95 C96 C100 Description Jaw Plate Tooth Plate MOQ 1 PCS Quality 100% Original Transport Package Standard Packing Specification Standard Size Trademark Hyton Origin Jiangsu China HS Code 84749000 Production Capacity 30000 Ton Per YearProduct Description

Nordberg Mining Crusher Jaw Spare Parts Jaw Plate Tooth Plate Suit Metso C110 Product DescriptionHigh manganese steel wear resistance parts wildely used in the Jaw Crusher , Cone Crusher,Impact Crusher, Gyratory Crusher and etc .HytonCasting produce High manganese casting liners mainly include Jaw Plate,Mantle, Bowl Liner, Feed Cone , Check plate, Arm Liner , Steel Ball ,and etc, Hyton's casting wear parts can suit lots of world famous crushing equipment brand suach as : Nordberg,Sandvic,Telsmith,Terex ,Symons ,Trio ,Kleeman ,Extec and etc.

Specification

Mainly suit the cone crusher model under below :

Met-so:C63 C80 C95 C96 C100 C110 C120 C130 C125 C140 C145 C150 C160 C200

Sand-vik:CJ408 CJ409 CJ411 CJ412 CJ612 CJ613 CJ615 CJ815 JM806 JM907 JM1108 JM1206 JM1208 JM1211 JM1312 JM1511 JM1513

Te-rex:J-1170 J-1175 J-1170AS J-1160 J-960 J-1480

Tels-mith:H2238 H2550 H3244 H3450

Tri-o:CT1030 CT1040 CT1048 CT1252 CT2036 CT2436 CT3042 CT3254 CT3254B CT3648 CT4254 CT4763 CT6080 .

Main Features

Company Profile

· Hyton(Jiangsu) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Jiangsu Province,Nantong City.

· As a new high-tech enterprise professionally manufacturing wear-resisting casting product which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton(Jiangsu) has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer.

· Established in June 2004, the company is now undertaking a National Torch Program Project, and five of its patented products have been honored as the "New High-Tech Product" of Jiangsu Province two of which have been listed into the New Products Program of Jiangsu Province.

· The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Jiangsu Province", the company has been appraised as a "Trustworthy" unit of Jiangsu Province for many consecutive years.

Testing & Shipping

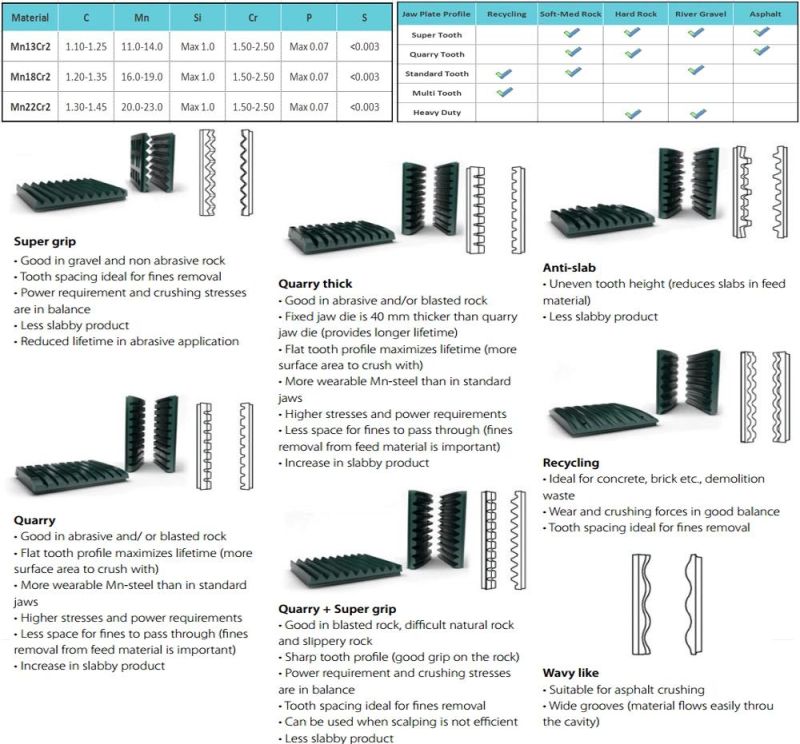

1.Raw Materail Inspection------ Sample Hot Metal,High Performance Raw Materail Ensure Long Service Lifetime (S<0.003, P<0.07)

2.Structural Inspection------Dye Penetration Inspection,Infrared Detection,Magnetic Particle Testing Provide Clean Surface And Higher Compactness.

3.Product Size Inspection------Repeated Examination For Mould and Parts Size,Promise Accurate Parts Outline

4.Hardness Inspection------100% As Same As Original Standard .

After-Sale Service

In the past 15 years, Hyton has always adhered to the principle of our mission "Serving the world with technology and service", adhere to the customer site, adhere to the scientific and pragmatic concept, taking the technology as the core driving force, constantly strive to provide customers with the best quality and efient service, and be well received by the industry.

We has established a set of perfect services structure. It is a "one -stop" work style "without worry service" system involved pre-sale, sells, post- sale as well as the technical support entire proess. Has formed a new business form Mainly include conventional technical support, user operation training, spare parts refurbishment, equipment and spare parts renting, equipment and spare parts leasehold, group user spare parts consignment cooperation mode, equipment escrow, production contract andother new business forms at the core.

FAQ

1.Q: Are you a foundry or trading company?

A: Our factory since 2004, we equip with complete facilities, all production process from manufacturing to testing isfinished in our own factory.

2.Q:What kind of products do you make?

A: We specialize in mining machinery spare and wear parts, widely suit for Jaw Crusher, Cone Crusher, VSI crusher, Impact Crusher...

3 Q:What kind of material do you offer?

A:High manganese steel, high chrome iron, alloy steel are currently the most regular material of us.

4.Q:What is your time of delivery?

A:Our lead time is generally 1~2 weeks for spare parts, 3~4 weeks days for wear parts.

5.Q:Do you offer the supporting service for technology and engineering ?

A:Yes. Our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

6. Q:How to test your quanlity?

A:We will show you material inspection and measurement inspection after fininsh the goods, at the same time we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first, all the good business relationship all from test and trust.