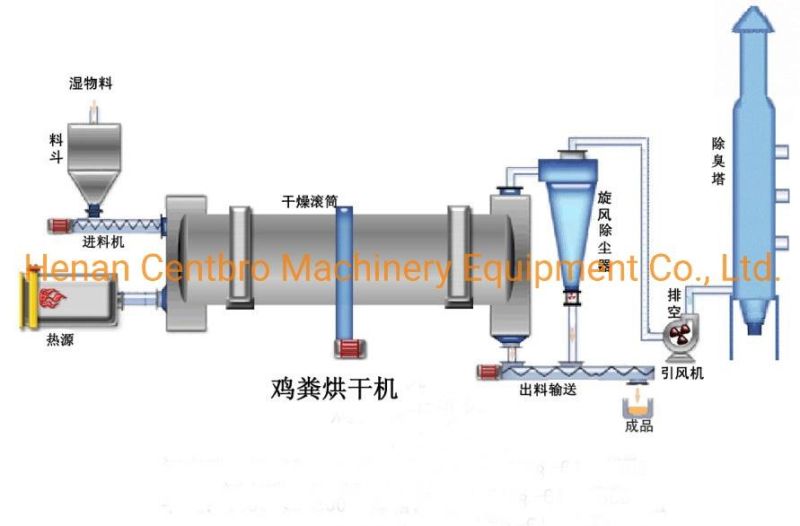

Mineral Processing Use Rotary Dryer for Zinc/Sliver/Copper/Iron ...

Henan Centbro Machinery Equipment Co., Ltd.- Model:3*6.5m

- Object:Clay

- Voltage:Customization

- Drum diameter:3m

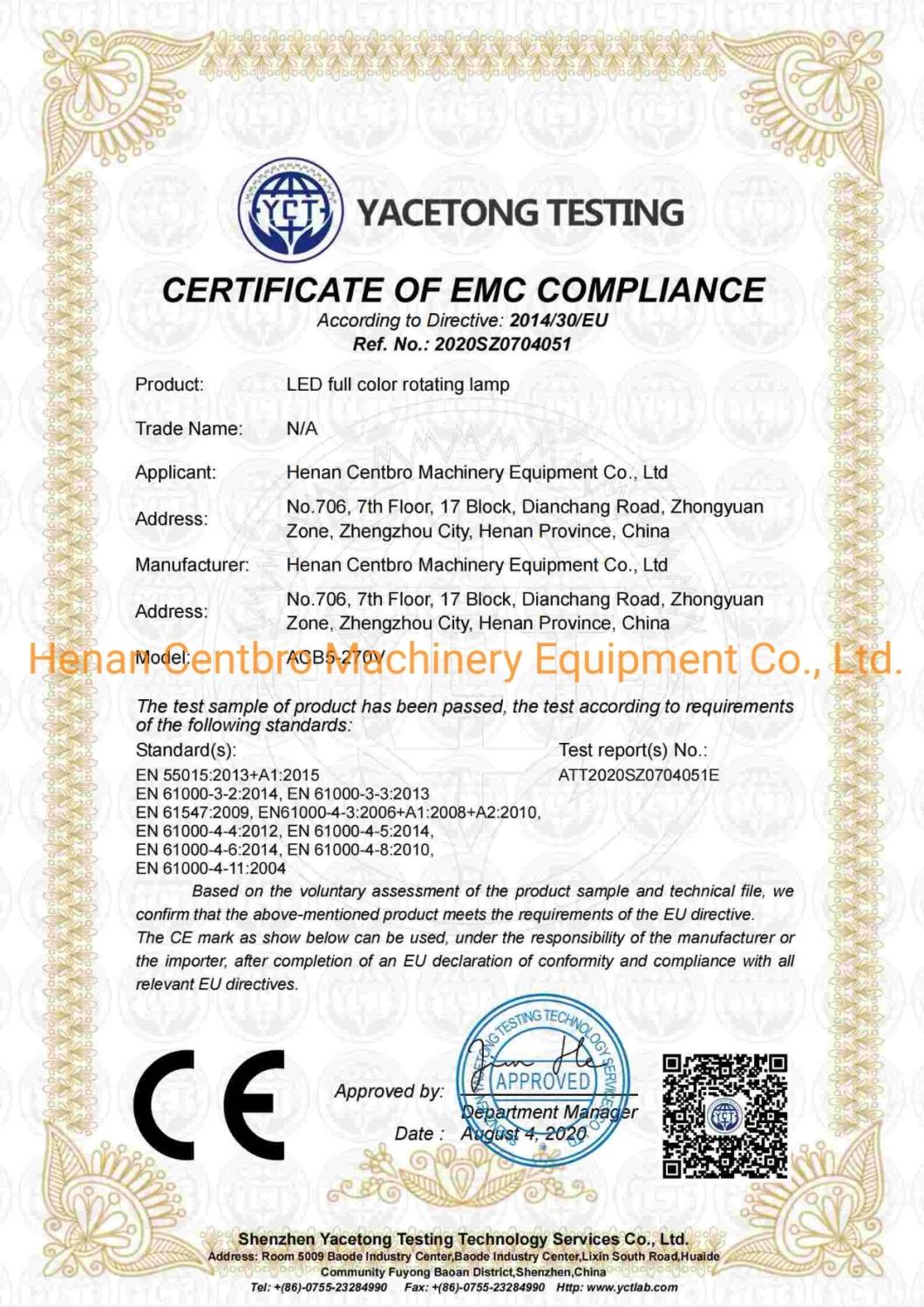

- Certification:ISO9001:2000, CE, TUV

- Energy Saving:Energy Saving

Base Info

- Model NO.:3*6.5m

- Warranty:1 Year

- Color:Customization

- Customized:Customized

- Condition:New

- After-sales Service:Engineer Working in The Site

- Outer Tube Lenght:6.5m

- Cylinder Volume:45.95

- Cylinder Rotating Speed:4-10r,Min

- Highest Inlet Air Tenperature:700-750

- Thoughput:35-40t,H

- Motor Power:11*4kw

- Transport Package:Eport Standard

- Specification:see the details

- Trademark:STM Centbro

- Origin:Zhengzhou, China

- HS Code:8419399090

- Production Capacity:10 Sets Per Month

Description

Product Details

Product Details

Benefits Features

Contact:

Trustworthy Brand: Henan Centbro Machinery Equipment Co., Ltd. is a large-scale enterprise, mainly engaged in the production of heavy mining machines, integrating scientific research, production, and sales. Our products have passed ISO9001, CE and GOST international certification. Choosing us will not disappoint you.

Packing

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Delivery

1.Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available.

2.We will remind you before boat arrival

Our Services & Strength

All machine are from Henan Centbro Mining Machinery are made by ourselves, with lower price, good quality and assured full after service.

So please buy machine from factory.

Pre-sale services:

We provide you with the proper plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the worksite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers

Support:

Support:We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support :

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support :

STM Group has been largely adopting new technologies, new techniques and high-tech equipment. And STM Group also has strict and effective quality control system. We have obtained ISO9001:2000, TUV and CEquality system certificate.