High Capacity Mini Cement Grinding Mill Plant

Henan Zhengzhou Mining Machinery Co., Ltd.- Production Scope:Product Line

- Automation:Automation

- Automatic Production Line:Reference Manual

- Flexible Production:Reference Manual

- Rhythm:Reference Manual

- Transmission Type:Reference Manual

Base Info

- Model NO.:ZK

- Installation:Under Our Engineer′s Guide

- Spares Parts:Supply for One Year Freely

- Certificate:ISO9001,ISO14000

- Working Hours:Continuous

- Transport Package:Standard Export Packing

- Specification:ISO9001, ISO14000

- Trademark:ZK

- Origin:Zhengzhou, China

- Production Capacity:Customized

Description

Basic Info.

Model NO. ZK Installation Under Our Engineer′s Guide Spares Parts Supply for One Year Freely Certificate ISO9001,ISO14000 Working Hours Continuous Transport Package Standard Export Packing Specification ISO9001, ISO14000 Trademark ZK Origin Zhengzhou, China Production Capacity CustomizedProduct Description

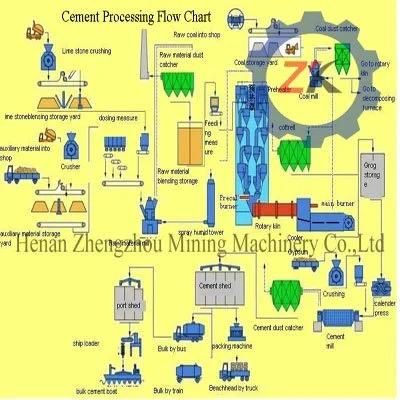

We Zk corporation have a large capacity in cement production line, which capacity from 100tpd to 3000tpd, , the national large-size enterprise and national market leader enterprise of Chinese building material industry, is an export base of cement equipments. We henan zhengzhou mining machinery Co., Ltd, can offer 150tpd-8000tpd clinker cement production line. And all of our products have passed by ISO9001: 14000.

Clinker cement machinery mainly has lifting equipment, drying equipment, grinding equipment, transmission equipment, dust removal equipment, and packaging equipment, etc. According to different plant design production planning, a variety of equipment also need to customize. Our company has a long-term production equipment design, manufacturing and installation experience. We have extensive experience for producing 1600 tons / day cement production line project. We can provide the appropriate technical support to all the clients, including select equipment model.

We carry out a detailed research on these fields: The proof of the technical program, the optimized of the technical process and the selection of the equipment function. We adopt an advanced and dependable DSC control system and network technology, In order to achieve the purpose that the cement production is high efficiency, energy saving and optimized control, to maximum reduce the number of the operated workers and the costs of the production. The construction of the production need about 21 months.

cement grinding:

Cement grinding is the final process of cement manufacture, but also the most power hungry process. The main materials through the cement clinker (and gelling agent, performance adjustment material etc.) grinding to appropriate particle size (in fineness, specific surface area, such that the outlet material) by the bucket elevator into high efficiency separator in the sorting, coarse powder grinding to grinding, cement products by the air box. Pulse bag type dust collector to collect after by air transport chute, bucket elevator sent to a repository.

Main Equipments for Cement Production Line

Rotary kiln, vertical preheater, cement ball mill, raw mill, air swept coal mill, rotary cooler, jaw crusher, DTIIfixed belt conveyor, bag filter, bucket elevator, screw conveyor, ZSW series vibrating feeder, coal burner and so on.

Company Name: Henan Zhengzhou Mining Machinery Co., Ltd.

Official Website: http://hnzkjq.en.made-in-china.com/ & http://hnzkjq.en.made-in-china.com/

24-hour Free Sales Consulting Phone : 861-0371 -5590 2866 .

Company Address: Qiaolou caizhai industrial estate, Xingyang city, Henan Province