Belt Type Permanent Magnet for Ilmenite (tailings) Separation

SLon Magnetic Separator Co., Ltd.- Type:Magnetic Separator

- Voltage:Customized

- Weight:>10T

- Material:Stainless Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2015

Base Info

- Model NO.:SPBC-2525

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Customized

- Customized:Customized

- Condition:New

- After-sales Service:Lifetime

- Capacity:35~40t,H

- Feed Density:10~35%

- Water Pressure:>0.2MPa

- Feed Size:<3mm

- Motor Power:4kw

- Transport Package:Seaworthy Packing

- Specification:SPBC-2525

- Trademark:SLon

- Origin:China

- HS Code:8474100000

- Production Capacity:30sets,Month

Description

Basic Info.

Model NO. SPBC-2525 Energy Saving Energy Saving Warranty 1 Year Color Customized Customized Customized Condition New After-sales Service Lifetime Capacity 35~40t/H Feed Density 10~35% Water Pressure >0.2MPa Feed Size <3mm Motor Power 4kw Transport Package Seaworthy Packing Specification SPBC-2525 Trademark SLon Origin China HS Code 8474100000 Production Capacity 30sets/MonthProduct Description

Features:• High intensity: The magnetic system is made of high-performance rare earth Neodymium iron boron material and is not easy to demagnetization;

• Large effective separation area: the maximum width and length of the magnetic separation surface can reach 2.5m and 3.0m respectively;

• Smooth surface of magnetic plate: The magnetic block and the magnetic plate are fixed in a unique way, which is firmly fixed and the whole surface of the magnetic plate is smooth;

• Uniform distribution: Two-stage buffering is adopted to distribute the material evenly, and the mesh is distributed evenly, so as to realize the uniform contact of the material in the direction of separation width;

• Clean iron unloading: multi-stage and multi-angle strong washing system is adopted to realize the complete separation of magnetic products and separation belts;

• Water and energy saving: intensive water supply pipeline is adopted to save water; A single device is driven by only one motor, which consumes less power.

Application:

It's suitable for iron removal and purification of non-metallic minerals such as quartz sand, potash feldspar, nepheline and kaolin, and also for magnetic product separation and recovery of metallic minerals such as hematite, limonite, manganese ore, wolfram, tantalum and niobium.

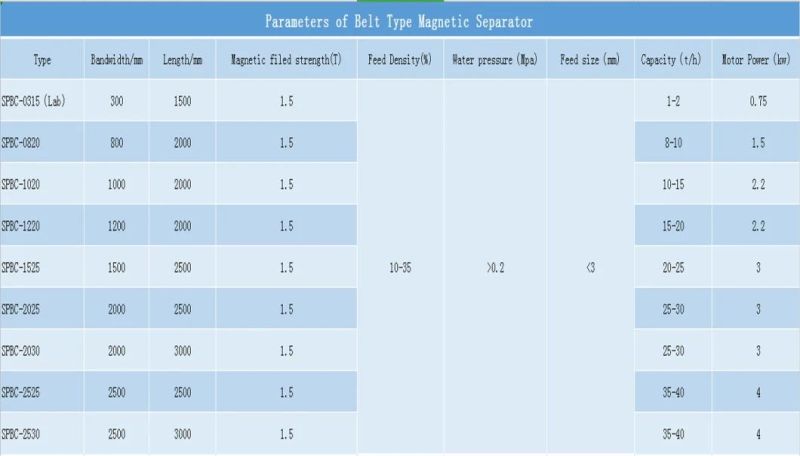

Technical Parameters

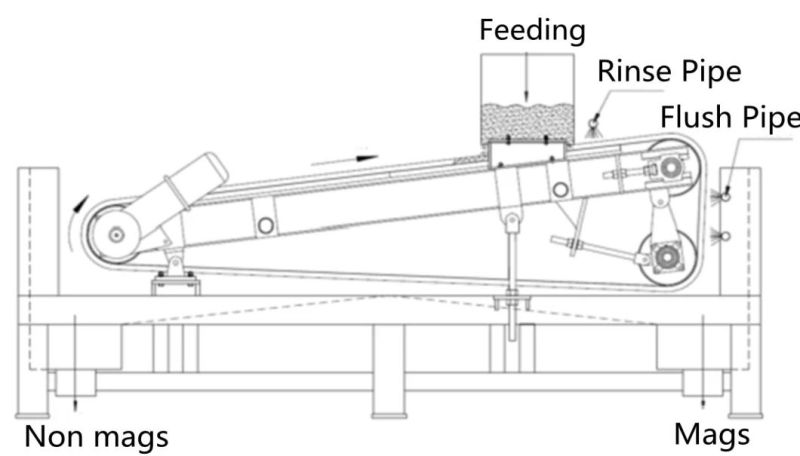

Working Principle:

The slurry enters the feeding box and flows out evenly on the belt with a thin layer through the bottom holes. The magnetic particles in the slurry are captured by the magnetic force of the magnetic system under the belt and adsorbed on the upper surface of the belt.Then the magnetic particles are intercepted by the raised rubber strip on the belt and moves upward with the belt.When it arrived the rinsing zone, the non-magnetic particles will be rinsed out from the magnetic particles.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and Wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.