High Performance Ore Processing Line Ore Processing Plant for Sale

Jiangxi Gandong Mining Equipment Machinery Manufacturer- Type:Gravity Separator

- Voltage:380V

- Weight:Depends on Quantity

- Material:Q235 Steel

- Certification:ISO9001:2008

- Energy Saving:Energy Saving

Base Info

- Model NO.:Gandong

- Warranty:1 Year

- Color:Blue

- Customized:Customized

- Condition:New

- After-sales Service:One Year for The Guarantee

- Application:Alluvial Ore, Placer Ore

- Capacity:5-300t,H

- Transport Package:Non-Packed Because Its Large Size

- Specification:As request

- Trademark:Gandong

- Origin:Jiangxi China

- HS Code:84741000

- Production Capacity:5 Lines,Month

Description

Basic Info.

Model NO. Gandong Warranty 1 Year Color Blue Customized Customized Condition New After-sales Service One Year for The Guarantee Application Alluvial Ore, Placer Ore Capacity 5-300t/H Transport Package Non-Packed Because Its Large Size Specification As request Trademark Gandong Origin Jiangxi China HS Code 84741000 Production Capacity 5 Lines/MonthProduct Description

High performance ore processing line ore processing plant for sale

Placer Gold Ore Gravity Production LineApplication

Placer gold ore dressing process is simple, usually through screening, gravity separation, cleaning separation can obtain good quality gold. But placer ore contains only a small amount of gold, is very limited, how can we ensure the return on investment of gold mining? This requires high performance, energy-efficient, large capacity, high recovery rate of dressing flow chart and dressing equipment.

Process Introduction

We use a process flow through jig machine for rougher, centrifugal concentrator for scavenger, shaking table and algamation for cleaner, ensure the capacity and the recovery rate at one time, Only in this way we can ensure economic benefit of dressing process of low grade gold ore. First, use wheel loader feed raw ore into trommel screen (or rotary scrubber) to remove rock and gravel, avoid rock and gravel into the jig machine effect the performance. The small sand which removed rock and gravel feed into the jig machine for gold separation, the rough concentrate get from jig machine feed into shaking table, after that the gold concentrate is produced. The tailing of jig machine put into vibrating screen to remove the sand bigger than 1mm, to guaranteed the feeding size reaches the best effective separation size range of centrifugal concentrator. The action of centrifugal concentrator scavenge the tailing of jig is to raise gold recovery for the whole process flow, to collect fine gold, flake gold which lost from jig machine as much as possible. The concentrate of centrifugal concentrator through algamation to obtain gold.

1. We are factory (NOT Dealer)

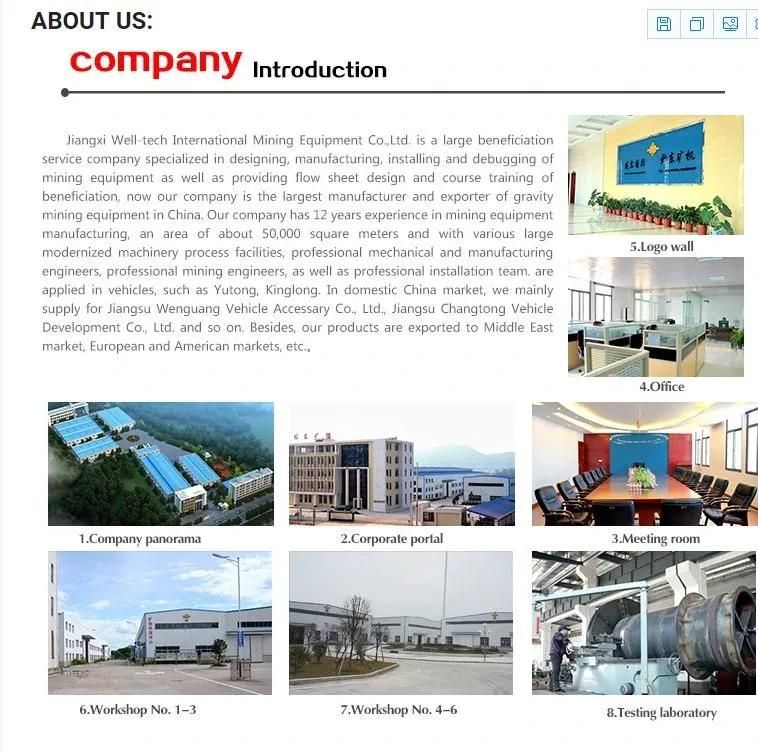

1. We are factory (NOT Dealer)All machinery from Well-tech international equipment Mining Machinery Manufactory are made by ourselves, No trade company make

Commission(many trade companies do not produce the machinery),the lower price with the same goods, good quality, after service can be assured (after service of trade companies will get help from factory).

So please buy from factory

2. We will do our best to satisfy every customer's needs

Producing high-quality and reliable machines is our first priority, because we know that our success depends entirely on the satisfaction of our customers. We never give-up quality to save cost.

3. Training & service

Training is FREE to every customer. Whenever you need us, for installation, maintenance, or proper use of our company machines, we will be right there for you. In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

4. If you are new for this business, I will help you

Many thanks for your trust; we can provide you with the pre-services of design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments, drilling rig, Loader, trucks, excavators and so on

5. We will recommend a suitable type for you and send you a best quotation

Our Services

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export

3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

Sales: Vicky