Pwc-B Series Hsi Stone Impact Crusher for Granite, Limestone and River Stone Crushing

Shanghai Duoling Watson Mining Equipment Co., Ltd.- Surface Treatment:Polishing

- Manufacturing Process:Forging

- Material:Carbon Steel

- Application:Mines, Quarries

- Crushing Stage:Secondary Crusher

- Partical Shape:Cubical Shape

Base Info

- Transport Package:Standard Export Package

- Specification:PWC-B-1310

- Trademark:Duoling

- Origin:China

- HS Code:8474209000

- Production Capacity:2sets Per Month

Description

Basic Info.

Transport Package Standard Export Package Specification PWC-B-1310 Trademark Duoling Origin China HS Code 8474209000 Production Capacity 2sets Per MonthProduct Description

PWC-B Series HSI Stone Impact Crusher for Granite , Limestone and River Stone CrushingIntroduction of HSI Impact Crusher

PWCB series impact crusher is manufactured with imported technology from U.K based on domestic actual situations, which can be employed in mines, quarries and road. PWCB enjoys many features which can ensure the best productivity for our customers.

Specifications of HSI Impact Crusher

| Model | Rotor Diameter (mm) | Rotor Effective Width (mm) | Input Size (mm) | Max.Feed Size (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| PWC-B-0808 | 800 | 800 | 830x294 | 200 | 20-30 | 37-55 | 5 |

| PWC-B-0812 | 800 | 1200 | 1230x294 | 200 | 30-40 | 55-90 | 7 |

| PWC-B-1010 | 1000 | 1050 | 2300x400 | 300 | 50-100 | 75-110 | 16.5 |

| PWC-B-1310 | 1300 | 1050 | 1170x490 | 350 | 70-120 | 110-160 | 16.3 |

| PWC-B-1314 | 1300 | 2300 | 1520x490 | 350 | 100-160 | 160-200 | 19.2 |

| PWC-B-1614 | 1600 | 2300 | 1430x500 | 400 | 130-220 | 185-250 | 30 |

| PWC-B-1621 | 1600 | 2100 | 2130x500 | 400 | 160-300 | 200-305 | 36 |

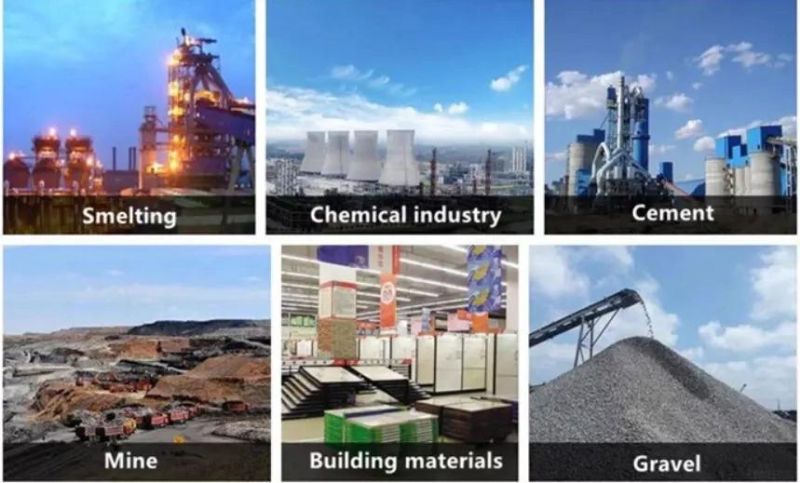

Application of HSI Impact Crusher

Secondary Crushing

Mining, Aggregate, Metallurgy, Industrial, Construction, Environmental

Working Principle of HSI Impact Crusher

Featuring a 4 rows of blow bars balanced rotor assembly, these machines offer smooth operation. When the impact crusher works, the motor drives the rotor rotating at a high speed, on which the blow bars installed. When the materials goes into the area where the blow bars takes the impacting force, under their impact function at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the blow bar works for being crushed again. The materials from large to small all to be crushed in the impact chamber repeatedly. The process won't stop until the materials are crushed to the required size and then discharged from outlet .