95% Convert Rate Coal Charcoal Powder Briquette Machine

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Pressing Mode:Twin-roller

- Product Shape:Oval Shape

- Motor Type:AC Motor

- Condition:New

- Color:as Per Requirement

- Bearing:Wafangdian

Base Info

- Model NO.:YYQ

- Roller Material:65mn,9cr2mo

- Delivery Time:30 Days

- Guarantee:12 Months

- Spare Parts Supply:Long Term, Good Price

- After Sale Service:Long Term

- Machine Type:Hydraulic Pressure

- Installation:Under Our Guide

- Transport Package:Container

- Specification:ISO9001: 2008

- Trademark:HC

- Origin:Henan, China

- HS Code:84748090

- Production Capacity:1-50 Ton,Hour

Description

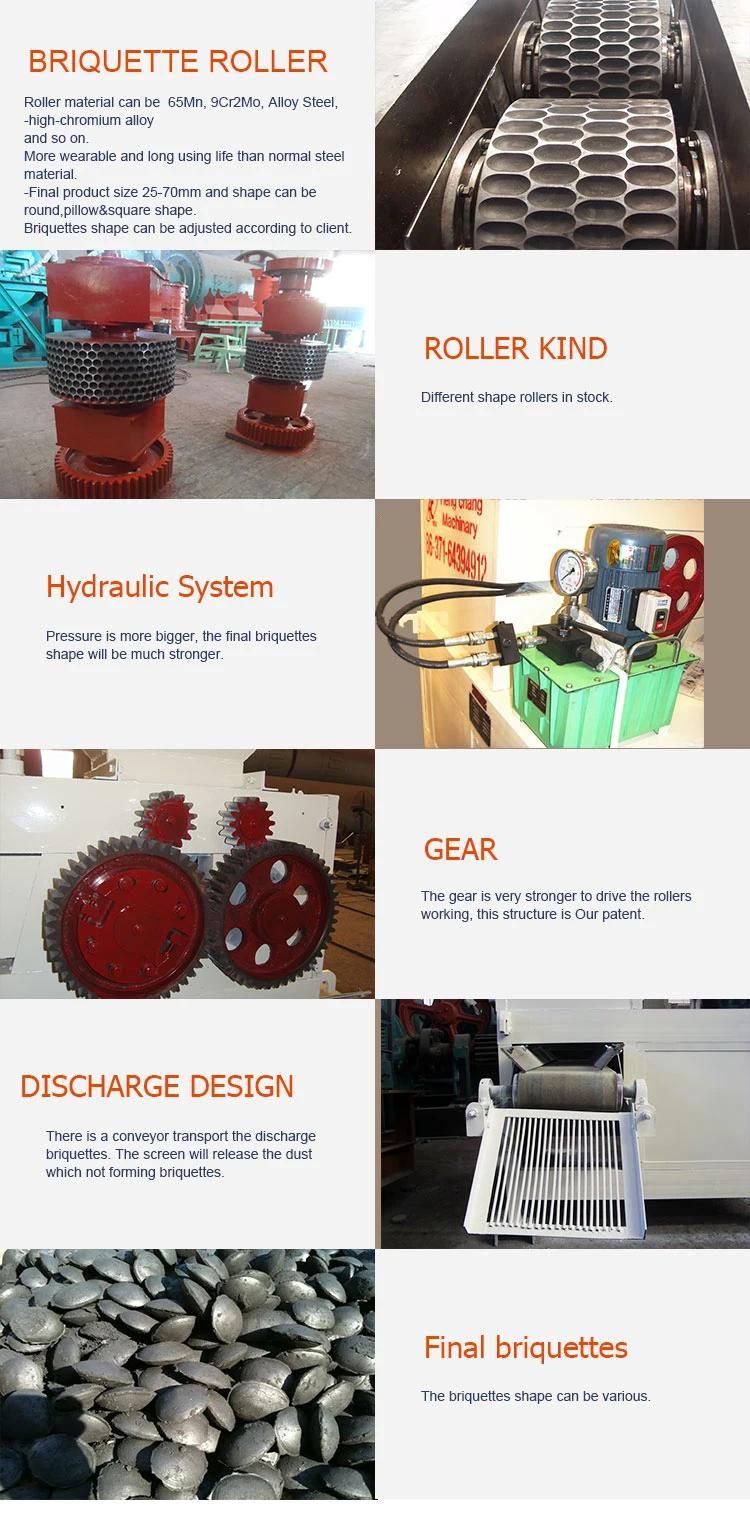

-Different type:Roller type,hydraulic type,high pressure type coal briquette machine

-Strong structure,high briquetting ratio because the briquette machine excellent design

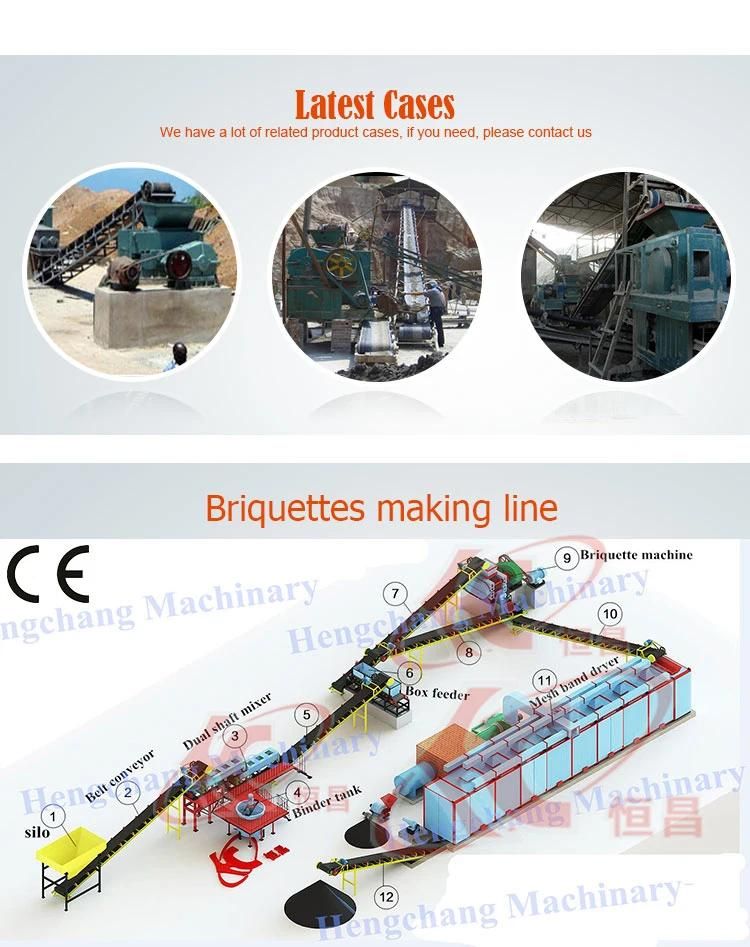

-it can be the single machine or whole production line.

-Roller material can be 65Mn, 9Cr2Mo, Alloy Steel, -high-chromium alloy

And so on

-Final product size 25-70mm and shape can be round,pillow&square shape.

-Engineer available for installation in customer country for briquette machine.

-provide the matched binder for the briquettes making.

-Engineer available for installation in customer country.

2.Charcoal powder/charcoal fine/charcoal dust

3.Gypsum/Desulfurization Gypsum/quicklime/slaked lime/

4.Activated carbon/carbon black

5.All kinds of metal powder/Manganese/magnesium/copper/iron

6.Iron oxide/aluminum oxide/clay

7.Some other type powder.

Height.Meanwhile, it is easy for combustion, no smell and last longer

When burning.The final product shape and the size can be design according

To you.Also,our engineer will suggest you the best size and shape for you.

2)Material moisture control in 8-10%.

3)Material with any metal objects can't be allowed,or else they will

Damage the rollor surface of machine.

95% Convert Rate Coal Powder Briquette Machine

Model

Roller dia.(mm)

Roller width

(mm)

Motor power

(kw)

Shaft speed(r/min)

Reducer model

Capacity

(t/h)

Pressure form

Roller material

YYQ-476

476

210

22/1.5

15

ZQ500

3-6

Hydraulic pressure

65Mn

YYQ -476

476

260

30/1.5

15

ZQ650

4-8

Hydraulic pressure

9Cr2M0

YYQ -500

500

300

30/1.5

15

ZQ650

5-9

Hydraulic pressure

65Mn/9Cr2M0

YYQ -650

650

336

45/1.5

15

ZQ750

8-15

Hydraulic pressure

65Mn

YYQ -672

672

275

75/1.5

13

ZQ1000

8-15

Hydraulic pressure

9Cr2Mo

YYQ -750

750

400

55/1.5

13

ZQ850

15-20

Hydraulic pressure

65Mn/9Cr2Mo

YYQ -850

850

500

75/1.5

10

ZQ850

20-30

Hydraulic pressure

65Mn/9Cr2M0

YYQ-1000

1000

650

110/1.5

10

ZQ1000

30-50

Hydraulic pressure

65Mn/9Cr2M0