Charcoal Lumps Roller Grinder with Mixing Efficience

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Raymond Mill

- Motor Type:AC Motor

- Motor Power:4kw

- Rotationl Speed:41r,Min

- Application:Construction

- Materials:Iron

Base Info

- Model NO.:S115

- Condition:New

- Keyword:Roller Wheel Grinder

- Installation:Engineer Guide

- Name:Charcoal Lumps Roller Grinder with Mixing Efficien

- Weight:900kg

- Color:According to The Customer

- Advantage:in⪞rease Material Solidity

- Model:S112

- Dis⪞ Diameter:1220 mm

- Feeding Quanitity:150kg

- Pressure:0-1200n

- Payment:T,T

- Price:Competitive

- Wheel Size:670*140mm

- Tootal Power:4kw

- Function:Mixing and Grinding Powder Material

- Transport Package:Wooden Package

- Specification:Refer to model

- Trademark:HC

- Origin:Gongyi City, Henan Province, China

- HS Code:84742090

- Production Capacity:2.5-40t,H

Description

S110

S112

S114

S116

S118

S120

S125

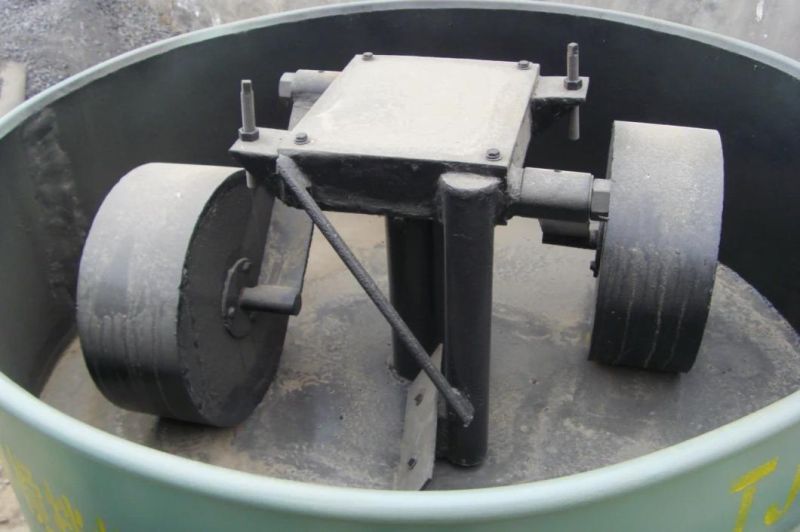

3. Working principle of Charcoal Lumps Roller Grinder with Mixing Efficience

Wheel grinding sand mixer mainly by the grinding wheel, grinding plate and drive the three major components. The relative movement between the grinding wheel and the grinding disc and the differential movement of the roller itself and through the sieve plate hole extrusion to achieve the purpose of processing raw materials. Our factory products are improved after the internal grinding wheel in the grinding plate on the non-perforated plate on the grind, the external grinding wheel will be grinding after the raw materials by grinding plate on the hole plate extrusion, and the screen plate hole shape and quantity and The arrangement has also been improved, both to improve the production, but also improve the overall performance of raw materials processing. Can be said to be a very good raw material processing equipment.

4. Main Features of Charcoal Lumps Roller Grinder with Mixing Efficience

(1)wheel mill structure is relatively simple, easy to manufacture and maintenance, feed size requirements are not too strict;

(2) There is no sieve on the plate, grinding mound lighter, there are specially designed discharge mechanism, to ensure the success of the feed material;

(3) in the mixing process both the crushing and squeezing role, can better remove the gap between the material particles, so that the raw material particles can be better moist and full;

(4) wheel mill machine light weight, low production capacity, but the energy power is larger, with great mixing effect, after grinding machine after the operation of raw materials, good quality, uniform size;

(5) Milling effect is good, the production efficiency is high, the energy saving effect is remarkable, the equipment is sealed well, the adaptability is strong, and the work process will not cause the extra environmental pollution. (6) wheel grinding machinery for a wide range of high economic efficiency. Can be adapted to refractory mud, fly ash, clay, tailings, slag, sand and other types of raw materials crushed and milled, processed materials through the coal pressure ball machine and other equipment to suppress, for refractory materials, ceramics, Building materials and other industries have good economic benefits.

5. Our service

(1) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client's factory.

(2)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3)Warranty:

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

6. Our copmany

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments.