-

Thrust Roller for Cement Rotary Kiln and Rotary Dryer

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design, and uses CAE software to simulate the casting process. Strictly according to the process procedures to produce high-quality rotary kiln thrust roller: wood mold - modelling - pouring - heat preservatio

-

Rotary Kiln Spare Parts Thrust Roller in Cement Industry

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design, and uses CAE software to simulate the casting process. Strictly according to the process procedures to produce high-quality rotary kiln thrust roller: wood mold - modelling - pouring - heat preservatio

-

Factory Price Thrust Roller for Rotary Kiln

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design, and uses CAE software to simulate the casting process. Strictly according to the process procedures to produce high-quality rotary kiln thrust roller: wood mold - modelling - pouring - heat preservatio

-

China High Quality Rotary Kiln Thrust Roller

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design, and uses CAE software to simulate the casting process. Strictly according to the process procedures to produce high-quality rotary kiln thrust roller: wood mold - modelling - pouring - heat preservatio

-

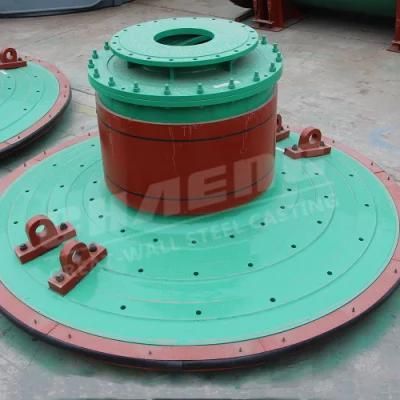

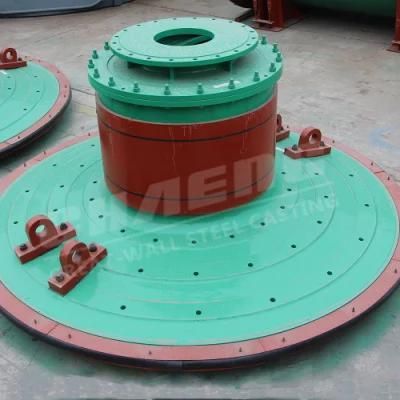

Large Casting Steel Ball Mill End Cover by Chinese Manufacturer

The first step: Simulation and modelingBefore casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize quality of ball mill end cover.The second step: pouring and heat treatmentSample the hot metal and perform the spectral analysis. After

-

Cement Ball Mill Spare Part Steel End Cover

The first step: Simulation and modelingBefore casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize quality of ball mill end cover.The second step: pouring and heat treatmentSample the hot metal and perform the spectral analysis. After

-

Hot Sale Ball Mill End Cover/Ball Mill Head

The first step: Simulation and modelingBefore casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize quality of ball mill end cover.The second step: pouring and heat treatmentSample the hot metal and perform the spectral analysis. After

-

Customized Casting Steel Ball Mill End Cover

The first step: Simulation and modelingBefore casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize quality of ball mill end cover.The second step: pouring and heat treatmentSample the hot metal and perform the spectral analysis. After