New Designed High Quality --Ball Mill by China Company

Xinxiang Great Wall Machinery Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:15KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Materials:Steel

Base Info

- Model NO.:Ball Mill

- Condition:New

- Installation:Installation

- Warranty:1 Year

- Transport Package:Transport Package

- Specification:20-380 t,h

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:20-380 T,H

Description

Basic Info.

Model NO. Ball Mill Condition New Installation Installation Warranty 1 Year Transport Package Transport Package Specification 20-380 t/h Trademark CHAENG Origin Henan Production Capacity 20-380 T/HProduct Description

China Ball Mill Product Profile

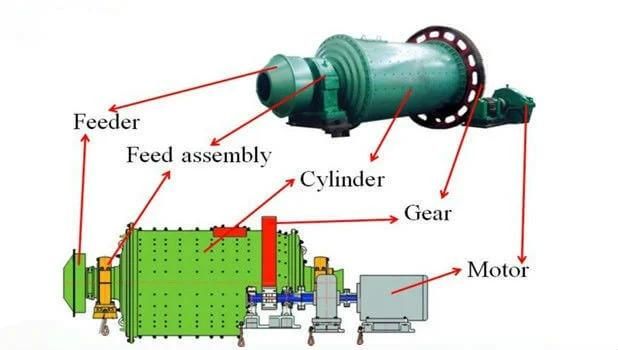

New Designed High Quality --Ball Mill by China Company is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on. The hollow axis adopts the cast steel and the lining can replace , the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scale board. This machine runs steadily and works reliably.

Ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries. It is widely used in Cement Plant, Clinker Grinding Unit, Quicklime Plant, Thermal Power Plant, Steel Mill, Mining

Ball Mill Working Principle

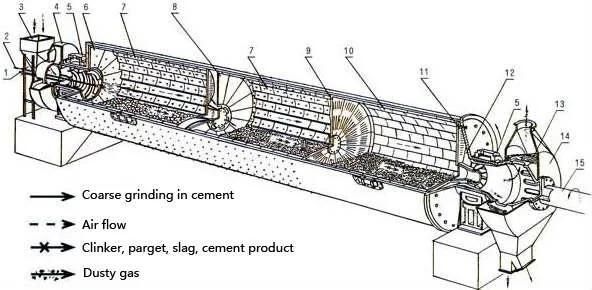

1. This ball mill machine, a horizontal type and tubular running device, has two chamber. This machine is grid type. The material enters first warehouse spirally and evenly along the input material hollow axis by input material device.

2. In this chamber, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls. When shell rotates and it produces centrifugal force. At this time, steel balls will be carried to certain height and falls down to make the material heavy impact and grinded.

3. After being grinded coarsely in the first chamber, material enters second chamber for regrinding with the steel ball and scaleboard. At the end, the powder is discharged by output material board and the final products are completed.

Structure characteristics:

1.There is high-quality wear-resistant liner in the cylinder. With strong wear resistance, its life time is lengthened effectively.

2.The double sliding belt structure is adopted, increasing the stability and running time of the equipment.

3.The advanced partition for powder selecting and discharge grate greatly improves the efficiency of grinding and selecting.

4.The gap between the bearing cage of sliding belt and the base is sealed with rubber and sealant. While working, the seal is strengthen to prevent the oil from leaking.

China Ball Mill Specifications

| Model | Output (t/h) | Rotate Speed (r/min) | Feeding Granularity (mm) | Grinding Media Load (t) | Effective Volume (m³) | Motor (kW) | Weight (t) |

|---|---|---|---|---|---|---|---|

| Φ2.4×13 | 21-23 | 20.3 | ≤25 | 65 | 51.7 | 800 | 116 |

| Φ2.6×13 | 28-32 | 19.61 | ≤25 | 75 | 60 | 800 | 149 |

| Φ3.0×13 | 33-37 | 18.08 | ≤25 | 108 | 80.9 | 1250 | 172.3 |

| Φ3.2×13 | 45-50 | 17.8 | ≤25 | 128 | 92.4 | 1600 | 218 |

| Φ3.2×14 | 48-52 | 18.04 | ≤25 | 138 | 99.8 | 1800 | 228 |

| Φ3.5×13 | 55-60 | 17.09 | ≤25 | 160 | 111.2 | 2000 | 250 |

| Φ3.8×12 (closed-circuit) | 110 | 16.6 | ≤25 | 175 | 123.6 | 2500 | 203 (excluding drive parts) |

| Φ3.8×13 | 66 | 16.4 | ≤25 | 195 | 129.3 | 2500 | 286 |

| Φ4.0×13 | 80-85 | 15.5 | ≤25 | 235 | 155 | 2800 | 220 (excluding drive parts) |

| Φ4.2×13 (closed-circuit) | 140-155 | 15.6 | ≤25 | 240 | 157 | 3550 | 287 (excluding drive parts) |

Company Information

Chaeng (Xinxiang Great Wall Machinery Corporation) located at National Sustainable Development Experiment Area, Mengzhuang Town, Huixian City, Henan Province, China, was initially built in 1958 and restructured into limited liability Company from township collective enterprise in 2002.

Covering an area of 330,000 m² and having more than 1,100 employees, the company has a total asset of CNY 500 million and has passed ISO9001:2008 quality management system authentication and is a main specialized supplier for manufacturing large scale kiln mill. Possessing the experience of equipment manufacturing for more than half a century, the Company has formed the perfect operation and management system in design and development, product manufacturing, market promotion, equipment installation and after sales service.

The Company once won the honors of High Growth Private Enterprise of Henan Province, The Top 100 Suppliers of China's Cement Industry in 2015, The Top 10 Innovative Enterprise of China's Cement Industry in 2015 and so on.