to Ku Hammer Hydraulic Breaker Chisel Tool Tnb150 for Excavator Hammer

Hebei Monteono Machinery Technology Co., Ltd.- After-sales Service:Online

- Warranty:6month

- Certification:CE, ISO 9001:2008

- Standard:GB

- Surface Treatment:Polishing

- Manufacturing Process:Forging

Base Info

- Material:42CrMo Tsg46A Tsg48A

- Application:Mining, Construction, Rock Drill

- OEM/ODM:Acceptable

- System:Hydraulic-Gas System

- Color:Customer Required

- Suitable Excavator:2.5-45 Tons

- Transport Package:Wooden Case, Pallet

- Specification:120kg 1240mm 177mm

- Trademark:MTON

- Origin:Hebei, China (Mainland)

- HS Code:8412210090

- Production Capacity:100000piece,Year

Description

1. More than 10 years of industry experience.

2. Good quality.

3. Large Stock.

4. Low Price.

5. Support OEM/ODM order.

6.First-class technical level.

7.Perfect after-sales service.

TO KU Hammer Hydraulic Breaker Chisel Tool TNB150 for Excavator hammer

We can produce and supply a full range of spare parts for most of hydraulic breakers, such as Cylinder, back head and front head, ring bush front cover, thrush bush, side bolts and thru bolts, piston and seal kits etc.

All of them are made of high quality raw materials and can be supplied in various design, The most competitive price and excellent after-sale service we are confident that you will completely satisfied with them when our products reach you

Products Character

1. The chisels our factory manufactured are made by 40CrMo steel to fully ensure products' density and performance.

2. Using advanced CNC machining to make accurate size, and paying special attention to each machining detail, to ensure them being equipped with bushings right.

3. Using advanced heat treatment technology, heating them by sectional type, which makes inside machine part be HRC48, abrasion part be HRC55. Meanwhile ensuring having superior wear-resistance and being not easy to break down.

Usage

Crushing things directly.

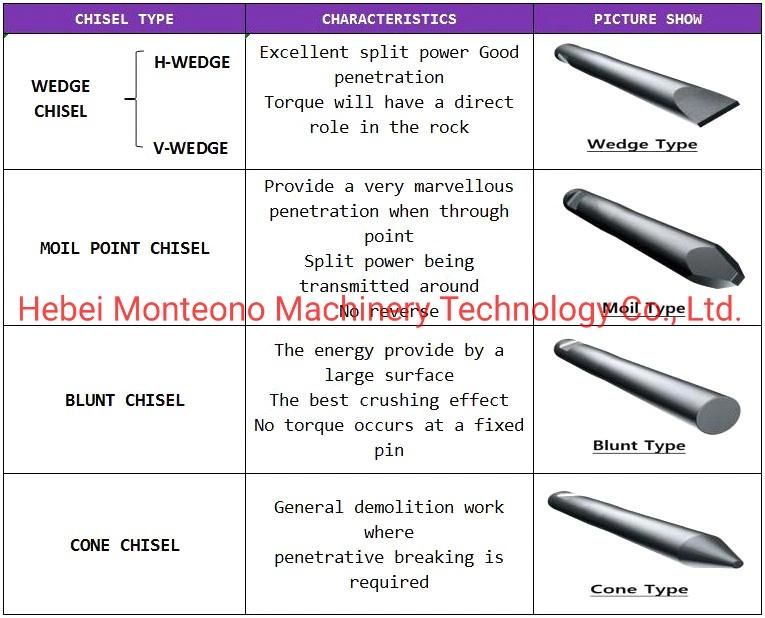

Type

Taper type, flat type, pyramid type, wedge type plain type, round type

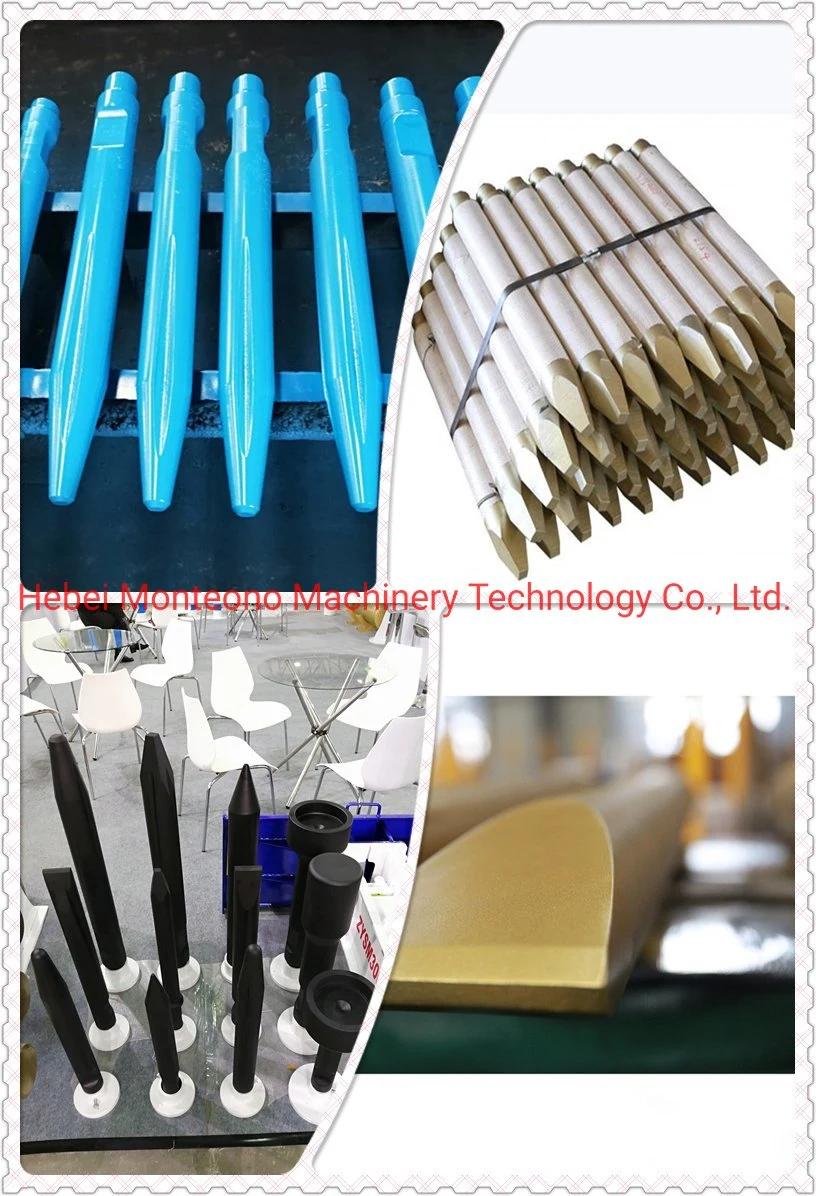

The processing of our products

Forging- Machiningheat- Treatment- Inspection- Lacquering&packaging

The quality is our mission and the integrity is the soul. We always insist to be sincerely to provide the high quality goods for all new and regular customer all the time. Please let us make the progress together.

Applicant:

Chisels for power tools as Bosch, Hitachi, used in cutting chiseling hole for concrete. Point Chisel/Flat Chisel/Groove ChiselAccessories for power tools as Bosch, Hitachi, Metabo, Hilti etc. Suitable for used with electric hammer in chiseling hole, cutting, chiseling groove for concrete and brick wall.

OEM is offered. We also produce per customer's order, any question feel free contact us, we are glad to support you the best service and a long term business.

Our company adopts high quality alloy steel products and advanced heat treatment technology, which makes the surface wear resistance ability and good core toughness, and ensure that the product will not crack under high intensity work.

FAQ

Q: Are you a manufacturer?

A: Yes,our factory was established in 2010.

Q: Are you sure your product will fit my excavator?

A: Our equipments are suitable for most excavators. Show us your excavator model, we'll confirm the solution.

Q: Can you produce according to customers' design?

A: Sure, OEM/ODM service available. We are professional manufacturer in Yantai.

Q: What's the MOQ and payment terms?

A: MOQ is 1set. Payment via T/T,L/C, Western Union accepted, other terms can be negotiated.

Q: How about delivery time?

A: 5-25 work days after the payment.

Q: How about the package?

A: Our equipments wrapped by stretch film, packed by pallet or polywood case; or as requested.

Q: Which country have you exported?

A: Saudi Arabia, America, Thailand, Cyprus, India, Canada, Australia, Peru, Egypt, Brazil, Mexico, Iran, South Africa, etc.

Contact Person:Irene Mei